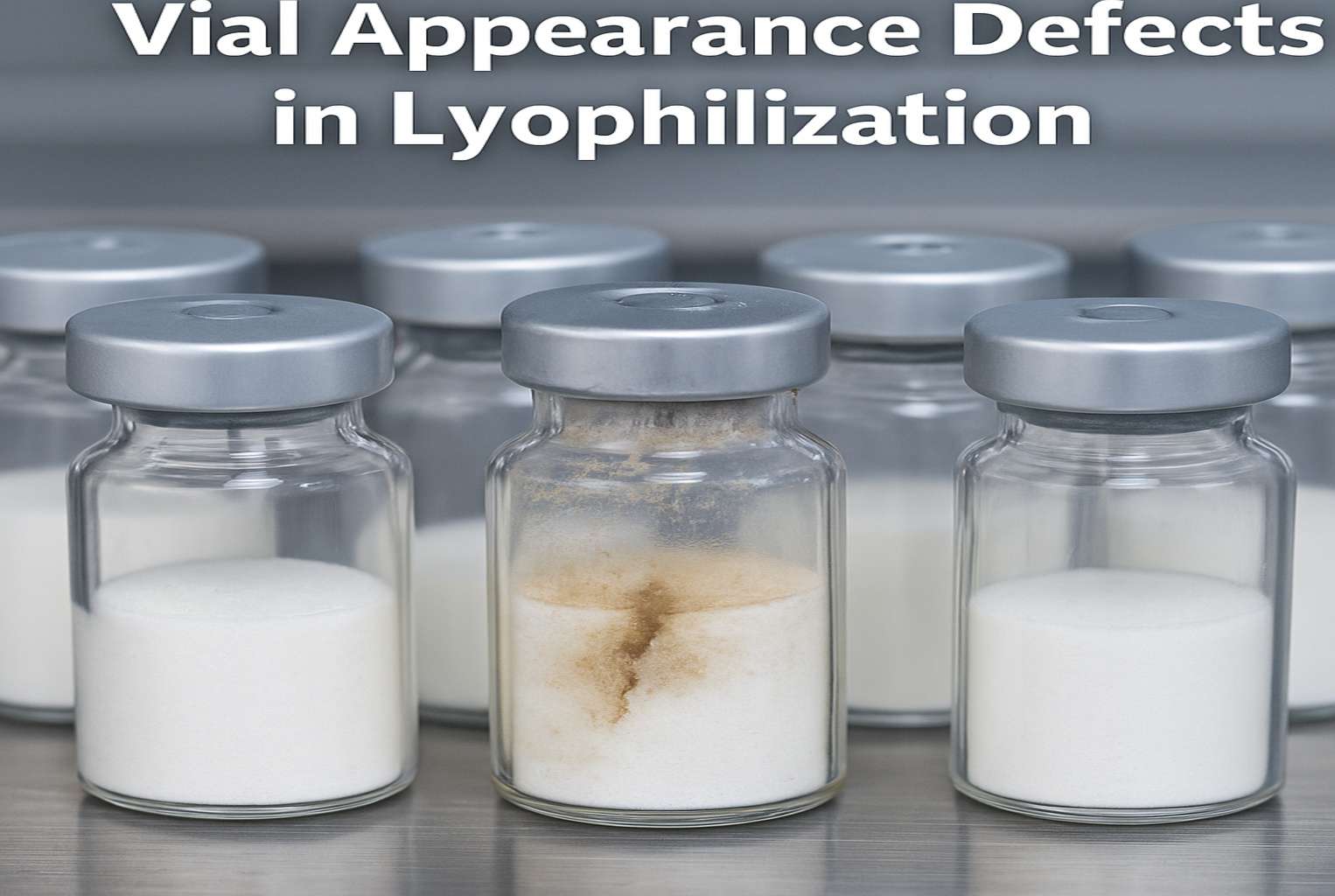

Lyophilization, or freeze-drying, is a delicate pharmaceutical manufacturing process that significantly extends the shelf life and stability of injectable drugs, biologics, and vaccines. However, during the lyophilization process, vial appearance defects can occur—impacting both the product’s perceived quality and its regulatory acceptability.

Vial appearance defects in lyophilization not only affect the visual aesthetics of the product but may also be indicators of more serious process or equipment-related issues. These defects can arise from improper handling, faulty sealing, glass integrity issues, or poor process control.

In this comprehensive guide, we will explore the various types of vial appearance defects, their causes, how they affect product quality, and what pharmaceutical manufacturers can do to prevent and manage them effectively.

Common Vial Appearance Defects in Lyophilized Products

Fogging or Haze on Vial Wall: A thin fog or cloudiness appears on the inner wall of the vial. Caused by vapor condensation or temperature fluctuations during drying.

Read: Demystifying Fogging in Lyophilized Products

Glass Particles: Visible or microscopic glass fragments due to vial breakage, delamination, or mechanical stress. Critical for patient safety and can lead to regulatory non-compliance. Learn more: Glass Particles in Injectable Drugs

Vial Discoloration: Yellow, brown, or black stains may appear due to contamination or reaction between product and packaging materials. Often linked to extractables and leachables. Detailed resource: Extractables and Leachables Issues

Scratched or Dented Vials: Cosmetic but may lead to regulatory rejection if recurrent. Common during transport or loading/unloading operations.

Seal Misalignment or Improper Crimping: Flip-off seal not seated correctly or uneven aluminum crimp. May lead to seal integrity failure. Also see: Freeze-Drying Process and Stoppering System

Color Variation on Seals or Labels: Inconsistent printing, coding, or color may affect product traceability.

Improper Cake Appearance: Collapsed, chipped, or discolored cake can reflect poor vial-vacuum interaction. Learn about cake defects: Defects in Lyophilized Product

Root Causes of Vial Appearance Defects

- Inadequate drying temperatures and vacuum levels

- Improper vial loading

- Vial-to-shelf heat transfer inconsistencies

- Poor stopper positioning

- Mishandling during capping or inspection

- Residual moisture and product splashing during freezing

Quality Control Measures

- Visual inspection under controlled lighting

- Use of automated inspection systems for seal, label, and cake consistency

- Routine monitoring of environmental conditions

- Qualification of cleanroom processes

- Refer to Freeze Dryer Batch Inspection Checklist

Regulatory Perspective

Appearance defects—even cosmetic ones—can lead to batch rejection if they compromise container closure integrity or mislead end users. According to cGMP and FDA guidelines, all units must be inspected and meet labeling, packaging, and product appearance specifications.

For compliance reference, see Pharmaceutical Regulatory Affairs SEC 211.44—Lighting.

Related Internal Resources:

- Understanding Dose Variation in Freeze-Dried Pharmaceuticals

- Foreign Matter in Lyophilized Product

- Defect Classification in Lyophilized Products

- How to Identify Critical Defects in Lyophilized Pharmaceuticals

- Lyophilized Product Quality Standards

FAQs on Vial Appearance Defects in Lyophilization

1. What are vial appearance defects in lyophilization?

Defects related to the external and internal appearance of the vial, cake, seal, or label.

2. Are appearance defects considered critical?

Some are cosmetic, but others—like glass particles or improper sealing—can be critical.

3. What causes fogging in vials?

Temperature fluctuations or rapid drying rates during freeze-drying.

4. How can scratched vials be avoided?

By using automated handling systems and careful tray-loading techniques.

5. Can vial discoloration affect product safety?

Yes, if caused by chemical interactions or contaminants.

6. What regulatory standards apply to appearance defects?

FDA and cGMP guidelines require visual inspection and rejection of non-conforming units.

7. What is the best way to detect appearance defects?

A combination of manual visual inspection and automated optical systems.

8. Can seal crimping defects lead to sterility failure?

Yes, improper crimping may lead to vacuum leaks and contamination.

9. Are label issues considered appearance defects?

Yes, especially if labels are missing, damaged, or incorrectly printed.

10. How can manufacturers reduce vial appearance defects?

By optimizing freeze-drying cycles, using high-quality packaging materials, and implementing strict QA protocols.