The commissioning of lyophilization units is a crucial step in the pharmaceutical and biotech manufacturing process. It ensures that freeze-drying systems are installed correctly, function as designed, and meet cGMP and regulatory requirements.

The commissioning process typically involves several stages, including design qualification (DQ), installation qualification (IQ), operational qualification (OQ), and performance qualification (PQ). Each stage is meticulously documented to verify that all components—from refrigeration systems to vacuum pumps and control panels—are working within specified parameters. Comprehensive testing also confirms uniform temperature distribution and pressure stability across the shelves, which are critical for product consistency.

This process minimizes the risk of failures during production and ensures the consistent quality of lyophilized products, including biologics, vaccines, and injectables.

What is commissioning in lyophilization?

Commissioning refers to the systematic process of verifying that a lyophilization unit—also known as a freeze dryer—is installed, configured, and operating in accordance with predefined specifications. It includes inspections, adjustments, and testing of all components, from vacuum systems to temperature controls, to validate performance before production use.

Importance of Commissioning in Freeze-Drying

The commissioning phase is essential because freeze-drying is a sensitive and complex process. Proper commissioning guarantees:

- Accurate temperature control across shelves

- Reliable vacuum levels

- Consistent sublimation and drying cycles

- Product and operator safety

- Regulatory compliance

Neglecting this step can lead to equipment failures, inconsistent product quality, or regulatory noncompliance.

To better understand how temperature accuracy impacts outcomes, refer to our guide on temperature control in freeze-drying processes.

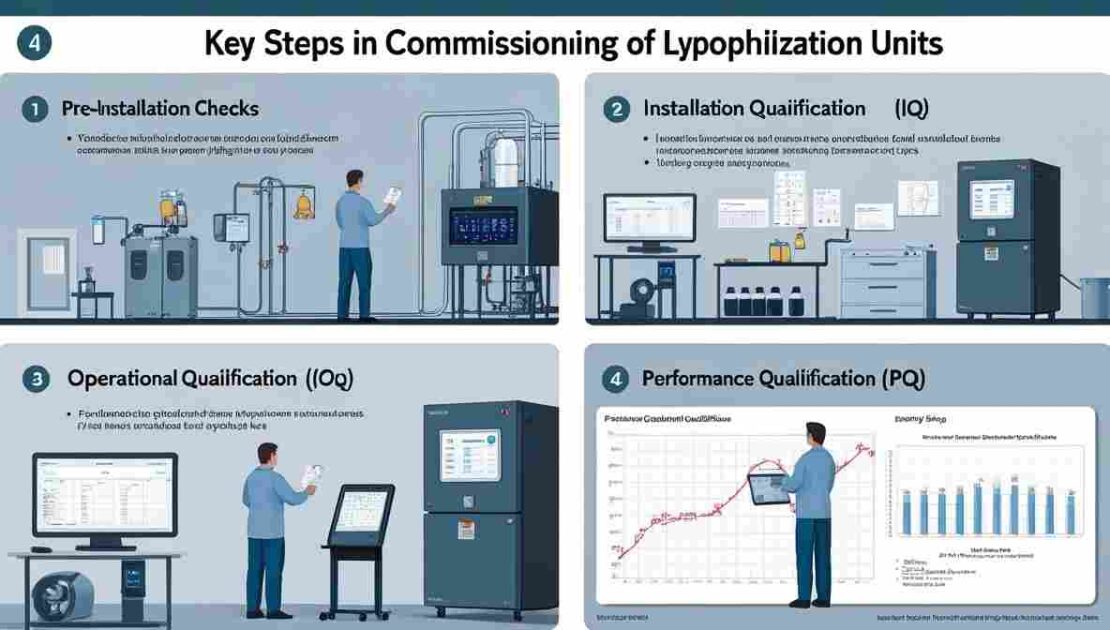

Key Steps in Commissioning of Lyophilization Units

Pre-Installation Checks

- Site validation

- Utility availability (power, water, clean air)

- Room conditions per lyophilization room requirements

This stage ensures that the lyophilization site is properly prepared. It includes validation of the room layout, checking the availability of essential utilities such as power, water, and clean compressed air, and verifying that environmental conditions meet lyophilization room standards.

Installation Qualification (IQ)

This step verifies that all components, including condensate preparation containers, vacuum pumps, and piping, are correctly installed. Learn more in our freeze-drying unit installation check.

IQ verifies that all components of the freeze dryer—such as condensate preparation containers, vacuum pumps, refrigeration systems, and piping—are correctly installed according to design specifications and manufacturer guidelines.

Operational Qualification (OQ)

Tests are performed under empty load conditions to ensure each component operates as expected. Read about our full freeze dryer operational qualification protocol.

In this phase, the system is tested under empty load conditions to ensure all components operate as intended. This includes verifying controls, alarms, sensors, and temperature and pressure parameters to confirm equipment functionality.

Performance Qualification (PQ)

This involves running actual freeze-drying cycles with product or product simulants to validate consistent performance. Reference our performance testing methodology for insights into test procedures.

PQ involves running actual freeze-drying cycles with product or product simulants to validate the system’s performance. It confirms the equipment consistently delivers the required results, meeting predefined quality and process standards.

Critical Components Inspected During Commissioning

- Vacuum Chamber Integrity: Verified through leak testing protocols

- Filter-Drier System: Ensures moisture and contaminants are removed. See details about the filter-drier cylinder

- CIP (Clean-In-Place) Functionality: Validated through CIP efficiency testing

- Compressor Checks: Problems like overheating can be addressed early. For example, compressor motor jacket cleaning is often necessary during commissioning.

Validation and Documentation

Commissioning is not complete without thorough documentation for audits and future troubleshooting. This includes:

- Base value verification: Verification of base values

- Condenser performance testing: Freeze dryer condenser capacity test

- Shelf heating and cooling rate verification: Shelf heating and cooling rate verification

- Filter integrity testing: Learn about the online filter integrity test

Regulatory Compliance and Risk Management

Proper commissioning helps ensure alignment with CGMP guidelines for lyophilized product manufacturing and reduces risks from contamination, temperature overshoots, or equipment failure. These issues are discussed in detail in our guide on the impact of temperature overshoots during lyophilization.

Final Thoughts

The commissioning of lyophilization units is not just a box-ticking exercise—it’s a foundational step toward achieving high-quality, stable, and compliant freeze-dried products. It builds the trust necessary for large-scale pharmaceutical production and ensures product consistency, safety, and market success.

For additional resources on commissioning, validation, and maintenance of freeze dryers, visit:

- Lyophilizer qualification guidelines

- Functional test of the freeze-drying process with remoisturing

- Process performance qualification

❓ FAQs – Commissioning of Lyophilization Units

What is commissioning in lyophilization?

Commissioning is the process of verifying that a lyophilization (freeze-drying) unit is installed correctly and operates according to design specifications. It includes system checks, testing, and validation steps before production.

Why is commissioning important in freeze-drying?

It ensures product quality, equipment performance, and compliance with cGMP regulations. Proper commissioning helps avoid process failures and production delays.

What are the key stages of lyophilizer commissioning?

The main stages are

- Pre-installation checks

- Installation Qualification (IQ)

- Operational Qualification (OQ)

- Performance Qualification (PQ)

How is performance qualification conducted?

Performance Qualification (PQ) involves testing the freeze dryer under real production conditions using product or placebo loads to confirm consistent drying performance.

What documents are required during commissioning?

Documents include base value verification, test results, calibration reports, system diagrams, and SOPs. These are necessary for audits and compliance.

Does commissioning include CIP and SIP systems?

Yes, Clean-in-Place (CIP) and Steam-in-Place (SIP) systems are tested to ensure cleaning and sterilization protocols meet industry standards.

Is leak testing part of commissioning?

A: Absolutely. Leak detection is critical to maintaining vacuum integrity. Refer to our freeze dryer leak test guide for more details.

How long does lyophilizer commissioning take?

It typically takes several days to weeks, depending on system complexity, documentation requirements, and the number of tests involved.

Where can I learn more about freeze dryer validation?

Visit our Lyophilizer Qualification Guidelines page for a complete breakdown of validation steps.