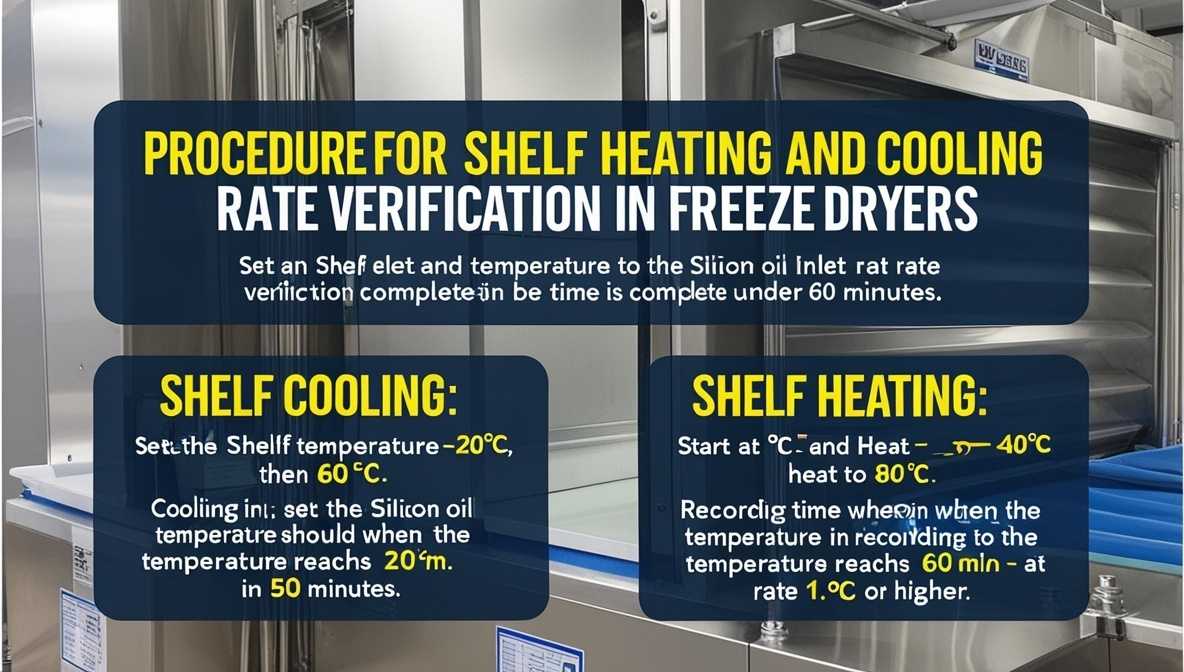

Shelf heating and cooling rate verification in freeze dryers is an essential procedure that ensures the accuracy and reliability of the lyophilization process. Since shelf temperatures directly influence the freezing, primary drying, and secondary drying phases, any deviation in heating or cooling performance can compromise product quality, stability, and compliance with pharmaceutical standards. By systematically verifying shelf temperature transitions, manufacturers can confirm that equipment operates within the required parameters for consistent results.

The verification process involves carefully monitoring shelf inlet temperatures during controlled heating and cooling cycles. For cooling, the shelves are evaluated on their ability to reach -40°C from 20°C within 50 minutes, while for heating, the transition from -40°C to 20°C must occur within 60 minutes at a rate of at least 1.0°C per minute. Recording these values in an observation table allows operators to validate performance against acceptance criteria, ensuring proper system function and early detection of deviations.

By conducting regular shelf heating and cooling rate verification, facilities can maintain compliance with Good Manufacturing Practices (GMP), enhance equipment reliability, and safeguard product quality. This verification not only prevents temperature-related issues during freeze-drying but also provides documented evidence for audits and regulatory inspections. Ultimately, it supports both operational efficiency and patient safety by guaranteeing consistent freeze-drying performance.

🔑 Key Takeaways

- Shelf heating and cooling rate verification ensures freeze dryer accuracy and reliability.

- Cooling verification: Shelves must reach -40°C from 20°C within 50 minutes.

- Heating verification: Shelves must reach 20°C from -40°C within 60 minutes at ≥1.0°C/min.

- Regular verification supports GMP compliance, product quality, and equipment reliability.

- Proper documentation provides evidence for audits and regulatory inspections

Shelf Cooling Rate Verification in Freeze Dryers

- Select Manual Mode.

- Set the shelf control temperature to 20°C. Enable shelf temperature regulation

- When the temperature of the silicon oil inlet is within 20.0°C+1.0°C, recode the shelf inlet temperature in observation table and record

- Set shelf control temperature to -60.0°C.

- When silicon oil inlet temperature reaches -40.0°C, the recorded shelves inlet Temperature

- Shelf Fluid IN <50 Minutes Temp. (°C) (Yes/No)

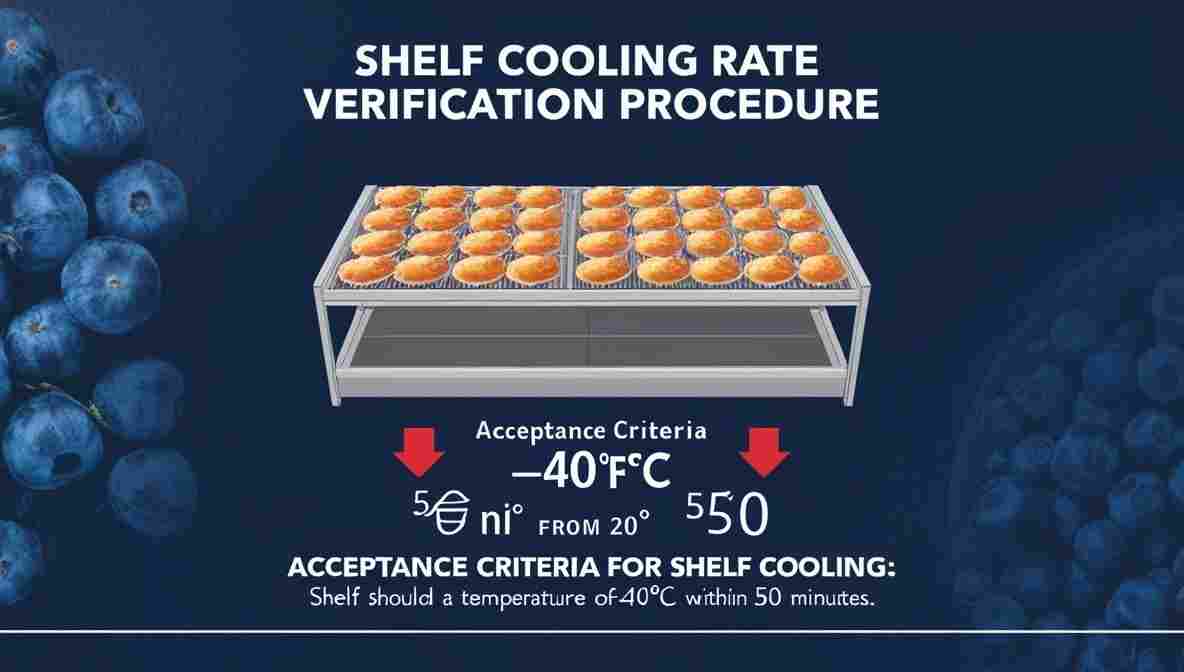

Shelf Cooling Rate Verification procedure

- Activate Manual Mode: Select the manual mode on the freeze dryer and set the shelf control temperature to 20°C. Enable shelf temperature regulation.

- Record Observations at 20°C: When the silicon oil inlet temperature stabilizes within 20.0°C ± 1.0°C, record the shelf inlet temperature in the observation table.

- Set Temperature to -60°C: Adjust the shelf control temperature to -60°C.

- Monitor and Record at -40°C: When the silicon oil inlet temperature reaches -40.0°C, record the shelves’ inlet temperature in the observation table.

Acceptance Criteria for Shelf Cooling: Shelves should achieve a temperature of -40°C from 20°C within 50 minutes.

To ensure seamless cooling, explore our comprehensive freeze dryer troubleshooting guide.

Shelf Heating Rate Verification in Freeze Dryers

- When the shelf inlet temperature reaches -40.0°C + 1.0°C, inlet temperature and time are recorded

- Set shelf temperature to 80.0°C.

- When the shelf inlet temperature reaches 20°C, time is Time-2 in observation table

Shelf Heating Rate Verification procedure

- Initial Observation: Begin with the shelf inlet temperature at -40°C ± 1.0°C. Record the initial temperature and time in the observation table.

- Set Temperature to 80°C: Adjust the shelf temperature to 80°C.

- Monitor and Record at 20°C: When the shelf inlet temperature reaches 20°C, record the time as Time-2 in the observation table.

Acceptance Criteria for Shelf Heating: Shelves must achieve 20°C from -40°C within 60 minutes, with a heating rate of 1.0°C/min or higher.

For detailed insights into heater performance, refer to our troubleshooting guide on excess heater temperatures during freeze-drying.

📊 Table: Shelf Heating and Cooling Rate Verification

| Process | Initial Setting | Target Setting | Observation Point | Acceptance Criteria |

|---|---|---|---|---|

| Shelf Cooling Verification | Set shelf control temperature to 20°C (stabilize at 20.0°C ±1.0°C) | Lower to -60°C | Record shelf inlet temperature when silicon oil inlet reaches -40°C | Shelves must reach -40°C from 20°C within 50 minutes |

| Shelf Heating Verification | Start with shelf inlet temperature at -40.0°C ±1.0°C | Increase to 80°C | Record shelf inlet temperature when it reaches 20°C | Shelves must reach 20°C from -40°C within 60 minutes at ≥1.0°C/min |

🔹 Difference Between Shelf Heating and Cooling Rate Verification

| Aspect | Shelf Cooling Rate Verification | Shelf Heating Rate Verification |

|---|---|---|

| Starting Point | Shelf is stabilized at 20°C | Shelf is stabilized at -40°C ±1.0°C |

| Target Temperature | Reduced to -60°C, observation at -40°C | Increased to 80°C, observation at 20°C |

| Process Nature | Cooling (temperature decreases) | Heating (temperature increases) |

| Acceptance Criteria | Must achieve -40°C from 20°C within 50 minutes | Must achieve 20°C from -40°C within 60 minutes with ≥1.0°C/min rate |

| Purpose | Ensures rapid and uniform cooling for product freezing | Ensures effective heating for sublimation and drying |

| Key Risk if Failed | Incomplete freezing, risk of product collapse or poor structure | Delayed drying, inefficient sublimation, possible degradation |

✅ Summary: Cooling verification checks how fast the shelves can drop temperature to freeze products properly. Heating verification checks how fast the shelves can rise in temperature to support sublimation and drying.

Importance of Verification

Shelf heating and cooling rate verification is a key part of ensuring uniform product quality, maintaining equipment reliability, and achieving compliance with pharmaceutical manufacturing standards. For further guidance on operational checks, explore our freeze-drying unit installation guide.