Condenser cooling rate verification is a crucial step in ensuring the efficiency and reliability of freeze-drying operations. The condenser plays a vital role in capturing water vapor during sublimation, and its ability to reach -40.0°C within the required timeframe ensures consistent product quality and system performance. Without proper verification, the freeze-drying process may face delays, reduced efficiency, or compromised results.

This verification process involves systematically recording the condenser’s temperature trend, documenting the start and end times, and comparing them against predefined acceptance criteria. By doing so, operators can confirm whether the system meets the required standards of performance and regulatory compliance.

Through structured monitoring, accurate observation, and proper documentation, Condenser Cooling Rate Verification provides assurance of equipment functionality. This practice minimizes risks, improves operational consistency, and supports the long-term reliability of freeze-drying systems.

Table of Contents

ToggleKey Takeaways – Condenser Cooling Rate Verification

- Condenser cooling rate verification is essential for ensuring freeze-dryer efficiency and product quality.

- The condenser must reach -40.0°C within 30 minutes to meet acceptance criteria.

- Accurate recording of start time (Time-1), end time (Time-2), and temperatures is mandatory.

- An observation table helps track performance and determine pass/fail results.

- Proper documentation, including trend screen prints and signatures, supports compliance and traceability.

- Any failure to meet the criteria requires investigation and corrective action before resuming operations.

- Regular verification ensures long-term system reliability, process consistency, and regulatory compliance.

Step-by-Step Procedure

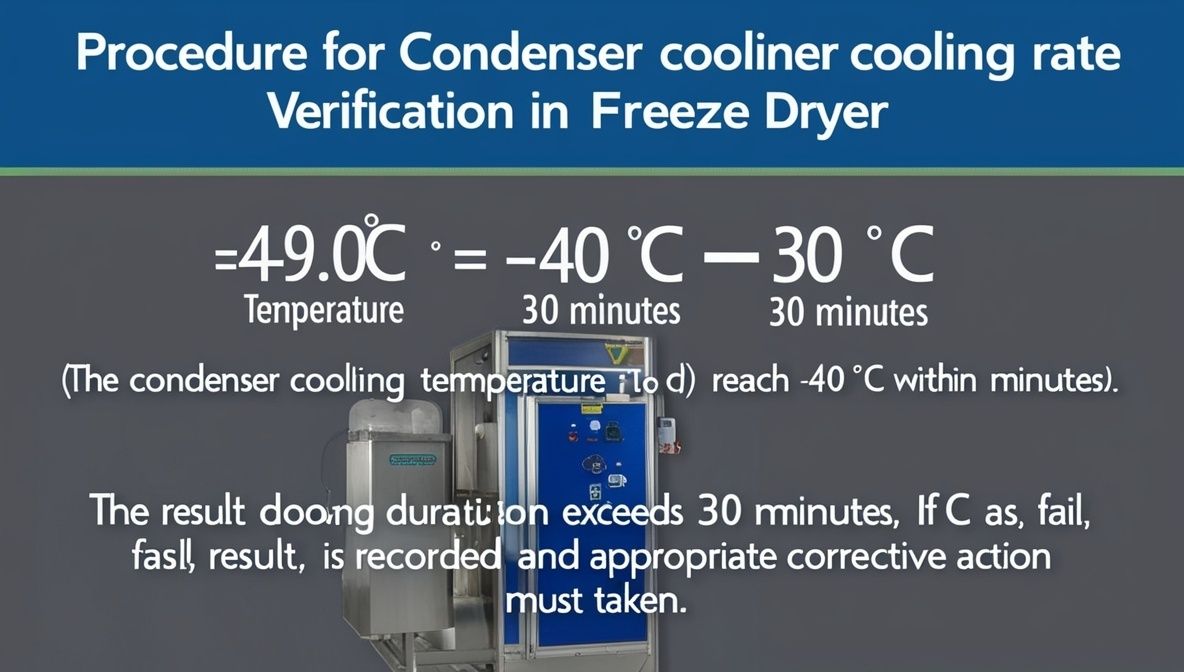

Completion of Leak Test: Perform and complete the leak test before starting the condenser cooling rate verification. Based on the trend, determine the time required to cool from ambient temperature to -40.0°C.

Initial Observations Record the ambient temperature and note the start time as Time-1 in the observation table. Monitor the condenser temperature trend on the system display.

Initiating Condenser Cooling: Switch to manual mode on the freeze-dryer system. Enable condenser cooling to begin the cooling process.

Monitoring Temperature Drop: Continuously monitor the condenser sensor temperatures. When one of the condenser sensor temperatures reaches -40.0°C, record:

- Condenser sensor temperature

- Time as Time-2 in the observation table.

Observation Table Details: Record the following details in the observation table for clarity:

| Time-1 (Start Time) | Condenser Temperature at Start (°C) | Time-2 (End Time) | Condenser Temperature at End (°C) | Difference (Minutes) |

|---|

Acceptance Criteria: Verify if the condenser temperature has reached -40.0°C within 30 minutes. Record the result as Pass or Fail in the observation table.

Observation Table Example

| Time-1 (Start Time) | Condenser Temperature (°C) | Time-2 (End Time) | Condenser Temperature (°C) | Difference (Minutes) | ≤30 Minutes (Yes/No) | Pass/Fail |

|---|---|---|---|---|---|---|

| 10:00 AM | 25.0°C | 10:25 AM | -40.0°C | 25 | Yes | Pass |

| 11:00 AM | 26.5°C | 11:35 AM | -39.5°C | 35 | No | Fail |

| 12:15 PM | 24.8°C | 12:45 PM | -40.2°C | 30 | Yes | Pass |

| 01:30 PM | 25.2°C | 02:10 PM | -38.9°C | 40 | No | Fail |

Key Considerations of Condenser cooling Rate Verification

- Ensure all data is accurately recorded in the observation table.

- Attach a trend screen print with the protocol for documentation purposes.

- Any deviation from the acceptance criteria must be reported and investigated.

Acceptance Criteria for Condenser Cooling

The condenser temperature should reach -40.0 °C within 30 minutes. If the cooling duration exceeds 30 minutes, the result is recorded as Fail, and appropriate corrective action must be taken.

This process ensures the condenser operates efficiently, maintaining system reliability and product quality during freeze-drying operations. For further troubleshooting, refer to your freeze-dryer’s user manual or consult a technical expert.

Conclusion of Condenser cooling Rate Verification

In conclusion, condenser cooling rate verification is an essential procedure for maintaining freeze-dryer performance and product integrity. By ensuring the condenser consistently reaches -40.0°C within 30 minutes, organizations can validate system efficiency, reduce risks of process failure, and maintain compliance with industry standards. Proper execution of this verification, along with accurate documentation, strengthens reliability and supports smooth freeze-drying operations

Summary of Condenser cooling Rate Verification

- Objective: Verify the condenser’s ability to cool from ambient temperature to -40.0°C within 30 minutes.

- Procedure: Record the start temperature and time (Time-1), enable condenser cooling, and monitor until the condenser reaches -40.0°C. Record the end temperature and time (Time 2).

- Acceptance Criteria: The condenser must reach -40.0°C within 30 minutes.

- Documentation: Maintain accurate records in the observation table and attach trend screen prints for validation.

- Outcome: Pass or fail is determined based on the condenser meeting the cooling time criteria.

Related Articles for Comprehensive Understanding

For more insights into freeze-drying processes, check out these guides:

- Shelf Heating and Cooling Rate Verification

- Freeze Dryer Shelf Package Installation Verification

- Freeze Dryer Condenser Capacity Test

- Troubleshooting Failure: Condenser Cooling Issues

- Lyophilizer Operational Qualification

FAQs related to condenser cooling Rate Verification

Why is condenser cooling rate verification important?

Condenser cooling rate verification ensures the equipment is functioning correctly, maintaining the efficiency and reliability necessary for successful freeze-drying processes.

What should I do if the condenser fails to reach -40.0°C within 30 minutes?

If the condenser fails, record the observation as “fail,” investigate potential causes such as insufficient refrigerant, system leaks, or compressor issues, and take corrective action before repeating the test.

How frequently should this test be performed?

This verification is typically performed during routine maintenance, after repairs, or when any deviation in performance is suspected.

Can I use any condenser sensor for temperature monitoring?

Yes, you can use any functional condenser sensor to monitor the temperature drop, as long as it provides accurate readings.

What documents should be attached to the protocol?

Include a trend screen print of the condenser cooling process, a completed observation table, and signatures from the personnel performing and checking the test.

What are common causes of condenser cooling failure?

Cooling failures can result from refrigeration leaks, faulty compressors, inadequate insulation, or system blockages.

What additional resources can help with freeze-drying processes?