NIR Spectroscopy Lyophilization: Advanced Real-Time Monitoring for Modern Freeze-Drying

Lyophilization has evolved rapidly over the past decade, and today, NIR spectroscopy lyophilization stands at the center of high-precision, real-time process monitoring. In modern pharmaceutical freeze-drying, ensuring consistent product quality, preventing defects, and reducing energy consumption have become essential goals. Because traditional monitoring methods rely on indirect measurements, manufacturers increasingly turn to Near-Infrared (NIR) spectroscopy as a reliable, non-destructive tool for tracking moisture content, solid-state structure, and critical drying endpoints.

In this comprehensive guide, you will learn how NIR spectroscopy integrates with freeze dryers, why it is emerging as a core PAT (Process Analytical Technology) tool, and how it improves efficiency, compliance, and product quality.

Introduction to NIR Spectroscopy Lyophilization

Although freeze-drying has been a critical technology in pharmaceuticals for decades, real-time monitoring remained a challenge. Traditional tools like Pirani gauges and thermocouples provide only partial insight. However, NIR spectroscopy lyophilization now enables full, in-process visibility by capturing the chemical and structural changes within the product throughout the cycle.

This key phrase will also appear naturally in headings and content for maximum SEO optimization.

Why Real-Time Monitoring Is Critical in Freeze-Drying

Real-time monitoring affects every major aspect of the lyophilization cycle, including:

- Optimizing primary drying times

- Avoiding meltback and collapse

- Ensuring proper secondary drying

- Reducing batch variability

- Improving energy efficiency

For deeper knowledge on monitoring methods, you may explore the guide on PAT in freeze-drying here:

👉 https://asitafreezedryer.com/pat-in-freeze-drying/

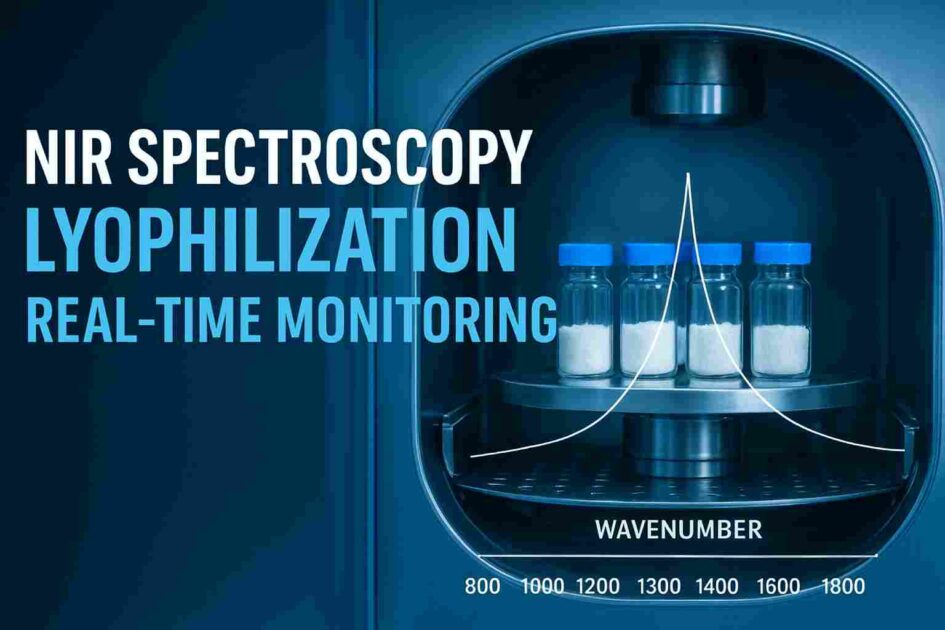

How NIR Spectroscopy Works in Lyophilization

NIR spectroscopy analyzes how molecules absorb near-infrared light. During freeze-drying, this absorption spectrum changes as:

- Ice sublimates

- Bound and unbound water decreases

- Crystalline structures transform

- Cake morphology stabilizes

Thus, NIR becomes an ideal non-invasive tool to observe moisture levels and solid-state changes without interrupting the cycle.

Key Advantages of NIR Spectroscopy Lyophilization

NIR offers several benefits that align with modern pharmaceutical requirements:

- Real-Time Moisture Estimation: Unlike gravimetric or endpoint testing, NIR continuously monitors residual moisture levels.

- Non-Destructive Testing: No vials need to be removed for sampling.

- Supports QbD (Quality by Design): Manufacturers can identify CPPs (Critical Process Parameters) effectively.

- Enhances PAT Frameworks: A combination of NIR and AI monitoring (see AI Monitoring: https://asitafreezedryer.com/freeze-drying-ai-monitoring-smarter-control-defect-prevention/) ensures strong process control.

Monitoring Primary Drying Using NIR Spectroscopy

Primary drying is the longest and most energy-intensive phase. NIR helps by:

- Detecting the end of ice sublimation precisely

- Avoiding prolonged drying

- Preventing meltback and cake collapse

Learn more about primary drying science here:

👉 https://asitafreezedryer.com/primary-drying-phase-optimization-strategies-models-and-results/

Secondary Drying Moisture Detection with NIR

NIR is widely recognized as the most accurate non-invasive tool for secondary drying monitoring because:

- It detects changes in bound water

- It matches Karl Fischer moisture results

- It ensures correct drying endpoint

Residual moisture directly impacts stability (see: https://asitafreezedryer.com/lyophilized-drug-stability/).

Applications in Biopharmaceuticals

Biopharmaceuticals require delicate drying due to sensitivity to structure and temperature.

NIR spectroscopy lyophilization is essential for:

- Monoclonal antibodies

- Cell and gene therapy products (related read: https://asitafreezedryer.com/freeze-drying-for-cell-and-gene-therapy/)

- Vaccines

- Peptides

- Enzymes

NIR vs Other PAT Tools in Freeze-Drying

| PAT Tool | Measures | Limitation |

|---|---|---|

| Pirani Gauge | Pressure | Indirect moisture detection |

| MKS Sensor | Absolute pressure | No chemical insight |

| Thermocouples | Product temperature | Risk of error or misplacement |

| NIR Spectroscopy | Chemical + moisture + structural info | Requires chemometric models |

Thus, NIR is the only PAT tool that provides a full chemical fingerprint inside the vial.

Equipment Integration and System Design

Modern freeze dryers allow NIR probes to be installed:

- Inside chamber walls

- On flexible fiber optic cables

- Above shelf levels

- Viewing selected vials

For details on chamber construction:

👉 https://asitafreezedryer.com/construction-of-freeze-dryer/

NIR Spectroscopy in Lyophilization 4.0

Lyophilization 4.0 aims to achieve the following:

- Automation

- Predictive analytics

- Integrated PAT tools

- Digital twins

- AI-assisted decision-making

NIR plays a core role in digital transformation. Read the full Lyophilization 4.0 guide:

👉 https://asitafreezedryer.com/lyophilization-4-0-smart-freeze-drying/

Improving Process Efficiency Through NIR

NIR shortens cycle times by:

- Identifying exact endpoint of primary drying

- Reducing unnecessary secondary drying by up to 30%

- Lowering energy consumption

For deeper info on improving efficiency:

👉 https://asitafreezedryer.com/lyophilization-process-efficiency-best-practices-for-optimized-freeze-drying/

Preventing Product Defects Using NIR Spectroscopy

Defects like

- Meltback

- Collapse

- White residue

- High moisture

- Cake shrinkage

can be detected early using NIR signals.

Explore defect analysis:

👉 https://asitafreezedryer.com/defects-in-lyophilized-product-a-complete-easy-guide/

NIR Models and Chemometrics

NIR requires advanced modeling tools:

- PCA (Principal Component Analysis)

- PLS (Partial Least Squares Regression)

- Multi-way chemometrics

- AI-based spectral interpretation

This helps differentiate between:

- Crystalline vs amorphous structures

- Free vs bound moisture

- Product phase transitions

Validation and Regulatory Acceptance

Regulatory bodies accept NIR under PAT and QbD frameworks.

To meet compliance, manufacturers must:

- Validate spectral models

- Establish calibration transfer

- Justify critical attributes

Learn more on cGMP compliance:

👉 https://asitafreezedryer.com/cgmp-guidelines-for-lyophilized-product-manufacturing/

Challenges and Limitations

Though powerful, NIR has limitations:

- Requires robust chemometric modelling

- Probe placement must be precise

- Sensitive to scattering effects

- Calibration may take time

However, its benefits outweigh challenges when implemented correctly.

Future Trends in NIR Spectroscopy Lyophilization

The future includes:

- AI-optimized NIR signals

- Hybrid PAT: NIR + Mass Spectrometry

- 3D moisture mapping

- Real-time digital twins

- Cloud-based monitoring systems

Explore AI-driven monitoring:

👉 https://asitafreezedryer.com/freeze-drying-ai-monitoring-smarter-control-defect-prevention/

Conclusion

NIR spectroscopy lyophilization is rapidly becoming the gold standard for real-time, non-invasive monitoring in freeze-drying. It improves product quality, ensures regulatory compliance, reduces cycle time, minimizes defects, and enhances control strategies under the PAT and QbD frameworks.

As the industry moves toward automation and lyophilization 4.0, NIR spectroscopy will continue to be a cornerstone technology for modern and future freeze-drying processes.

FAQs related to NIR spectroscopy lyophilization

1. What is NIR spectroscopy lyophilization?

It is the use of near-infrared spectroscopy to monitor real-time moisture and structural changes during freeze-drying.

2. Why is NIR useful in freeze-drying?

Because it provides non-invasive, chemical-level data directly from the product.

3. Can NIR replace thermocouples?

Not entirely, but it provides more comprehensive product insights.

4. Is NIR accepted by regulatory agencies?

Yes, as part of PAT and QbD approaches.

5. Does NIR reduce cycle time?

Yes, by detecting accurate drying endpoints.

6. Can NIR detect product defects?

It can detect early signs of meltback, collapse, or high moisture.

7. How is NIR installed in a freeze dryer?

Through probes placed inside the chamber or fiber optic systems.

8. Is NIR useful for biologics?

Absolutely—especially for sensitive cell-based and protein formulations.

9. What data does NIR provide?

Moisture levels, structural transitions, and chemical signatures.

10. Does NIR require calibration?

Yes, robust chemometric models are needed for accuracy.