Freeze-Drying Temperature Chart: Essential Guide. Did you know freeze-drying can keep food, medicines, and biological samples fresh for up to 25 years? This method, also known as lyophilization or cryogenic drying, changes the game in preservation and storage. Knowing the right freeze-drying temperatures lets you use this technology to its fullest for your needs

In this article, we’ll explore the significance of the Freeze-Drying Temperature Chart, detailing the key temperature parameters for every stage of the process. Whether you are preserving pharmaceuticals, biological samples, or food products, mastering these temperature ranges will help you optimize the freeze-drying process and deliver consistent, high-quality results.

Freeze-drying, also known as lyophilization, is a crucial process utilized in various industries, including pharmaceuticals, food preservation, and biotechnology. This method involves removing moisture from a product while preserving its structure and integrity. One key aspect of freeze-drying is the temperature chart, which outlines the temperature ranges crucial for different stages of the process. In this article, we’ll delve into the significance of the freeze-drying temperature chart and its role in achieving successful freeze-dried products.

Key Takeaways

- Freeze-drying can preserve items for up to 25 years, making it a game-changer in the world of preservation and storage.

- Understanding the critical freeze-drying temperature parameters is key to unlocking the full potential of this valuable technology.

- This guide provides an essential freeze-drying temperature chart to help you optimize the lyophilization process.

- Learn the key temperature parameters and techniques for successful freeze-drying, including cryogenic drying and vacuum dehydration.

- Optimize the freeze-drying process for food, pharmaceuticals, and biological samples with the help of this comprehensive resource.

- For a broader perspective on lyophilization trends, check out the Lyophilized Drugs Market Trends 2025-2030.

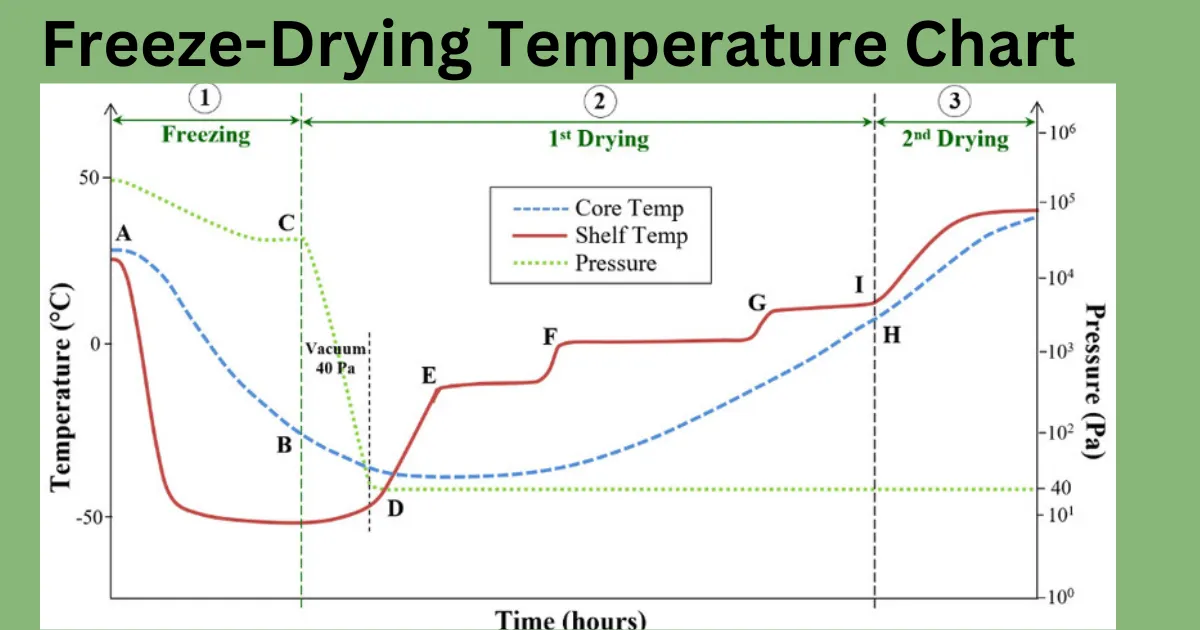

Freeze Drying Temperature Chart

The freeze-drying temperature chart is key for food, pharmaceutical, and research experts. It shows the best temperature ranges for each step of the freeze-drying process. This ensures products are preserved well and meet quality standards.

The freeze-drying temperature chart lists the best temperatures for freezing, primary drying, and secondary drying. It helps manufacturers and researchers maintain the right lyophilization parameters for successful cryogenic drying cycles. This keeps products or samples safe and effective.

For food producers or pharmaceutical scientists, the freeze-drying temperature chart is a must-have. It helps you get the right temperature for your products. This way, you can make sure your products last longer and are in top quality.

For a more detailed guideline on temperature control in lyophilization, check out Lyophilization Temperature Guidelines.

Here’s a simple table of the freeze-drying temperature chart.

| Phase | Temperature Range |

|---|---|

| Initial Freezing | 0°C to -50°C |

| Primary Drying Phase | -30°C to -10°C |

| Secondary Drying Phase | 0°C to 20°C |

| Final Drying Phase | 20°C to 60°C |

Loading stage

After starting the freezer, the loading temperature is achieved, then the freezer door is opened on the aseptic area side, and the empty and filled vials are loaded into the freezer. The freezing cycle is then started by SCADA (Supervisory Control and Data Acquisition) systems, which are used for controlling and monitoring the freeze drying process or

Loading stage: Once the freeze dryer is started and the loading temperature is reached, the door is opened in a sterile area. Empty and filled vials are then loaded into the freeze dryer before initiating the freezing cycle using SCADA.

Science of Freezing

- Water freezes at 32°F, releasing a small amount of heat as ice crystals form.

- Food has a lower freezing point than water due to its complex composition (e.g., sugar, tissue, air).

- Slow temperature drop during freezing in food allows gradual ice crystal formation.

- Each food freezes differently depending on its content (water, sugar, muscle, air).

Initial Freezing Phase (0°C to -50°C) or freezing

The freeze-drying process begins with the initial freezing phase. During this stage, the product is rapidly frozen to temperatures ranging from 0°C to -50°C. Freezing solidifies the water content in the product, forming ice crystals. Proper freezing is essential to ensure uniform distribution of ice crystals, which is crucial for efficient sublimation in subsequent stages. For insights into freeze dryer vacuum performance, visit Vacuum Chamber Lyophilization.

Primary Drying Phase (-30°C to -10°C)

Following the initial freezing, the primary drying phase commences. In this phase, the temperature is maintained between -30°C and -10°C. The primary drying phase involves sublimation, where ice transitions directly from solid to vapor without passing through the liquid phase. This process is facilitated by creating a vacuum. Which lowers the pressure and allows ice to sublime effectively. For insights into freeze-drying process failures, check out Failure: Compressor Excess Temperature During Freezing.

Secondary Drying Phase (0°C to 20°C)

Once the primary drying phase is complete, the secondary drying phase begins. During this stage, the temperature is gradually raised to a range of 0°C to 20°C. While most of the water is removed during primary drying, residual moisture may still remain in the product. The secondary drying phase aims to eliminate this residual moisture through desorption, ensuring the product’s stability and shelf life. For a comprehensive freeze-drying unit leak test, refer to Freeze-Drying Unit Leak Test: A Comprehensive Guide.

Final Drying Phase (20°C to 60°C)

The final drying phase marks the conclusion of the freeze-drying process. In this phase, the temperature is further increased to a range of 20°C to 60°C. The goal is to remove any remaining traces of moisture and ensure the product is completely dry. Final drying helps prevent microbial growth and degradation, preserving the quality and integrity of the freeze-dried product. For more information on lyophilized drug stability, read Lyophilized Drug Stability.

Venting Before Stoppering

After completion of the secondary drying process, the venting process done with the help of plant nitrogen or pure nitrogen as per recipe provisional present in batch manufacturing records For a deep dive into vacuum performance verification, refer to Vacuum Performance Verification: A Comprehensive Procedure.

Stoppering stage

After completing the secondary drying process, half the vials are fully stoppered in the freeze dryer using the stoppering force applied by the shelf.

Door opening process

After completion of the venting and stoppering stage, reach the unloading temperature for door opening, then open the door from aseptic area side and start the process of freeze-drying vials unloading with the help of ALUS (automatic loading and unloading system) for capping.

Unloading stage

After completion of the freeze-drying and stoppering stage, reach the unloading temperature, open the door on the aseptic area side, and unload the freeze-dried product. (lyophilized vials) one by one shelves

Remark: During unloading, always remove vials starting from the higher shelves. For example, if the freeze dryer is loaded from shelf 01 to shelf 10 during filling, then after completion of the freeze-drying process, unloading should be carried out in reverse order — beginning from shelf 10 down to shelf 01.”

Conclusion

Understanding the freeze-drying temperature chart is essential for achieving optimal results in the freeze-drying process. Each phase of the chart plays a critical role in removing moisture while preserving the product’s structure, texture, and nutritional content. By adhering to the specified temperature ranges and carefully controlling the process parameters, manufacturers can produce high-quality freeze-dried products with extended shelf life and enhanced stability. As technology advances, innovations in freeze-drying continue to improve efficiency and broaden their applications across various industries. For additional insights into freeze-drying efficiency, check out Lyophilization Cycle Development Guide for Success.