Drying is a critical process in the pharmaceutical industry, as it ensures product stability, potency, and extended shelf life. Traditional drying methods, such as hot air drying or freeze-drying, have been widely used for decades.

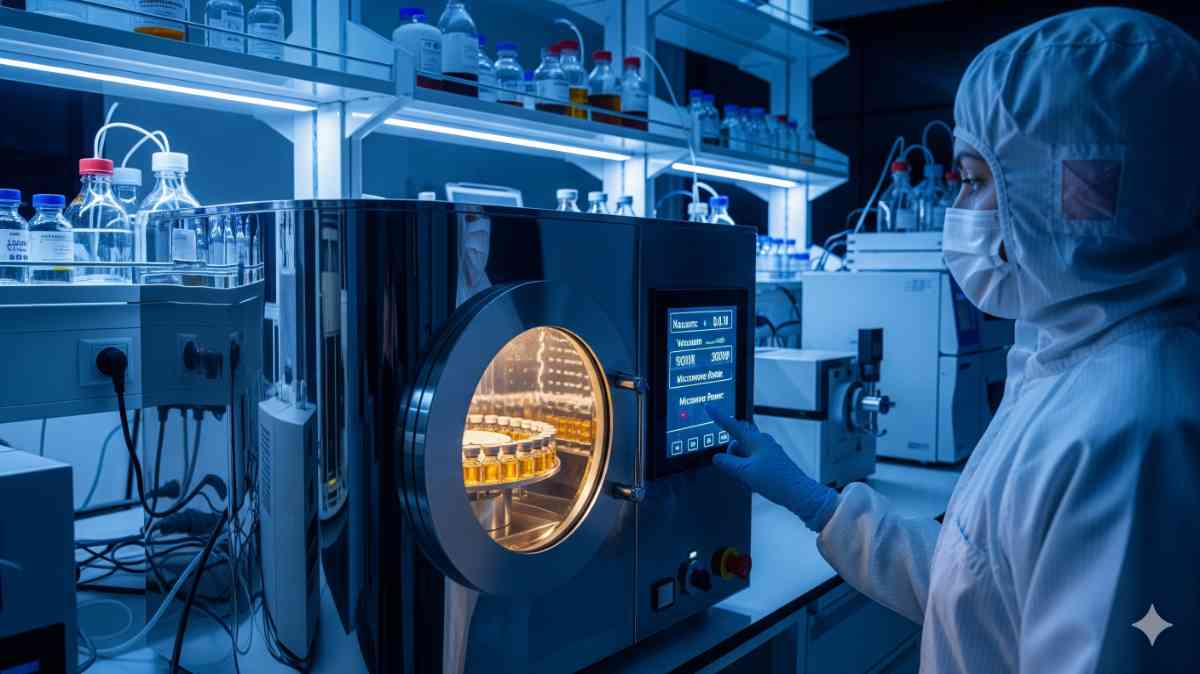

However, innovative techniques are emerging that offer faster, more energy-efficient, and cost-effective results. One such technology is Vacuum Microwave Drying (VMD).

This method combines the advantages of vacuum drying and microwave energy to deliver rapid moisture removal without compromising product quality. Due to its unique mechanism, vacuum microwave drying in pharmaceuticals has become a promising alternative for heat-sensitive drugs, herbal extracts, and biological materials.

Key Takeaways

- VMD combines vacuum pressure and microwave heating.

- It offers faster drying, higher energy efficiency, and better preservation of active compounds.

- Ideal for heat-sensitive drugs, herbal extracts, proteins, and vaccines.

- Challenges include higher costs and scalability, but ongoing innovations are improving adoption.

- Plays a vital role in the future of pharmaceutical drying technologies.

What is vacuum microwave drying?

(VMD) is an advanced dehydration process that integrates two powerful mechanisms:

- Vacuum Environment: Lowers the boiling point of water, allowing moisture to evaporate at lower temperatures.

- Microwave Heating: Provides uniform and rapid heating by directly exciting water molecules within the product.

This combination reduces drying time significantly while protecting sensitive compounds from thermal degradation.

Advantages of Vacuum Microwave Drying in Pharmaceuticals

- Faster Drying Time—VMD drastically reduces drying cycles compared to conventional drying methods.

- Energy Efficiency – Uses less power by targeting water molecules directly, minimizing energy loss.

- Preservation of Active Ingredients—Heat-sensitive compounds, such as enzymes and proteins, remain stable.

- Better Product Uniformity—Microwave heating provides consistent moisture removal throughout the product.

- Improved Porosity – Produces a porous structure, making rehydration easier for oral or injectable drugs.

- Reduced Contamination Risk – The closed vacuum system reduces microbial growth and contamination.

- Environmentally Friendly – Consumes less energy and reduces carbon footprint compared to traditional dryers.

Applications in Pharmaceuticals

- Drying of Herbal Extracts—Maintains bioactive compounds in medicinal herbs.

- Protein & Enzyme Preservation – Protects delicate molecules from thermal denaturation.

- Drying of Antibiotics and Vaccines – Provides stability without destroying sensitive active ingredients.

- Oral Solid Dosage Forms – Enhances solubility and bioavailability of drugs through porous structures.

For a detailed comparison of other advanced drying methods, you can explore our guide on vacuum microwave drying in pharmaceuticals.

Challenges of Vacuum Microwave Drying

While VMD offers multiple benefits, some challenges exist:

- High Equipment Cost – Initial investment is more expensive than conventional dryers.

- Process Optimization Needed – Requires precise control over temperature, vacuum, and microwave intensity.

- Scale-Up Issues—Industrial-scale VMD systems are still developing.

Conclusion

Vacuum microwave drying in pharmaceuticals is a breakthrough technology that bridges the gap between efficiency and product safety. By combining vacuum and microwave energy, it ensures faster drying cycles, enhanced stability, and energy savings, making it a promising solution for modern pharmaceutical manufacturing.

As the demand for cost-effective and high-quality drug production grows, VMD is expected to become a key technology in the pharmaceutical drying landscape, alongside traditional freeze-drying and spray-drying techniques.

FAQs on Vacuum Microwave Drying in Pharmaceuticals

What is vacuum microwave drying (VMD) in pharmaceuticals?

VMD is an advanced technique that combines vacuum pressure with microwave heating to rapidly remove moisture from pharmaceutical products while protecting heat-sensitive compounds.

How does vacuum microwave drying work?

The vacuum lowers the boiling point of water, allowing evaporation at lower temperatures, while microwave energy excites water molecules directly, enabling fast and uniform drying.

Why is VMD important in the pharmaceutical industry?

VMD ensures faster drying cycles, preserves active ingredients, enhances drug stability, and reduces energy consumption compared to conventional methods.

Which pharmaceutical products benefit most from VMD?

Heat-sensitive drugs, herbal extracts, proteins, enzymes, antibiotics, vaccines, and oral solid dosage forms are ideal candidates for VMD.

How does VMD compare with traditional drying methods like freeze-drying?

While freeze-drying is effective, VMD is significantly faster, more energy-efficient, and often better at preserving bioactive compounds, though it has higher initial equipment costs.

Is VMD environmentally friendly?

Yes, VMD consumes less energy and reduces the carbon footprint compared to traditional hot air or freeze-drying methods, making it a greener alternative.

What are the major challenges of using VMD in pharmaceuticals?

Challenges include high equipment costs, the need for precise process optimization, and difficulties in scaling up for industrial production.

Can VMD replace freeze-drying completely in pharmaceuticals?

Not entirely. While VMD is faster and efficient, freeze-drying is still preferred for certain sensitive biological products. However, VMD is emerging as a strong complementary technology.

What is the future outlook for VMD in the pharma industry?

With ongoing innovations to reduce costs and improve scalability, VMD is expected to play a major role in modern drug manufacturing, especially for heat-sensitive and bioactive compounds.