Why Lyophilized Cakes Collapse During Freeze-Drying: Causes, Consequences, and Lyophilization (freeze-drying) is a delicate process widely used in pharmaceuticals to stabilize heat-sensitive drugs, vaccines, and biologics. A common challenge encountered during this process is collapse of the lyophilized cake—a serious defect that impacts product quality, stability, and marketability.

In this comprehensive guide, we explain why lyophilized cakes collapse during freeze-drying, identify critical causes, and provide effective preventive strategies based on GMP and cGMP standards.

Table of Contents

Toggle🔬 What Is Cake Collapse in Lyophilization?

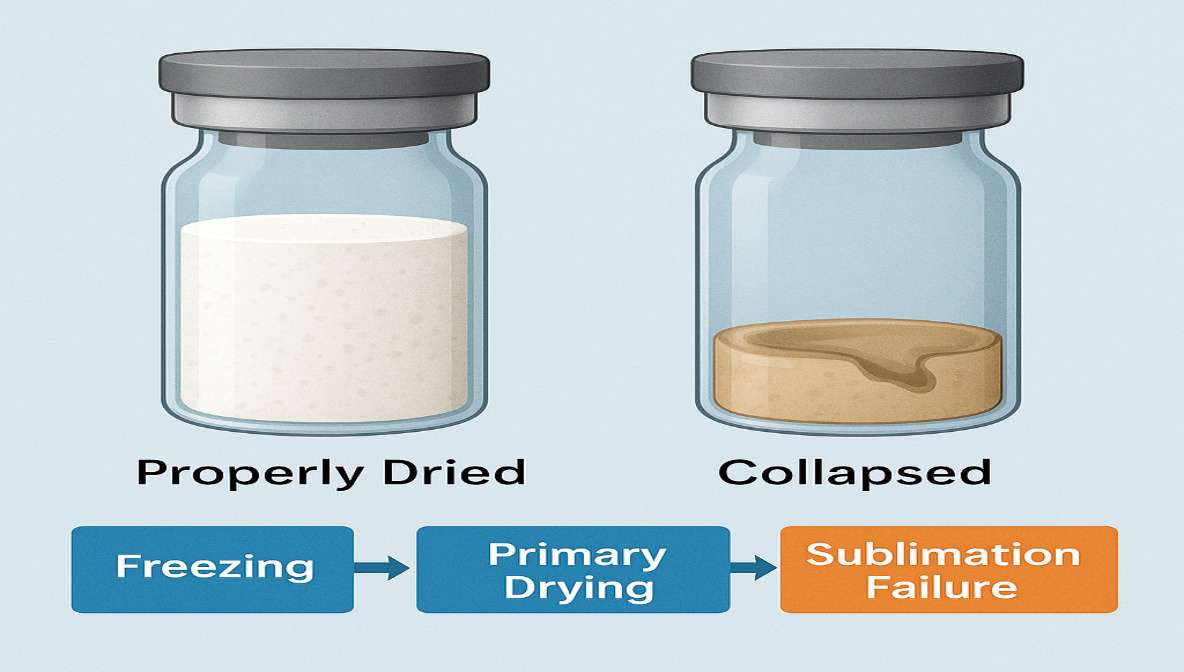

Cake collapse refers to the physical breakdown or structural distortion of the dried solid mass (cake) inside the vial during or after the freeze-drying process. Instead of a firm, porous structure, the cake may appear sunken, sticky, melted, shrunken, or gummy. A collapsed cake typically

- Fails visual inspection

- Indicates poor thermal control

- Affects product reconstitution time

- May reduce product efficacy and stability

🧊 Primary Causes of Cake Collapse in Freeze-Drying

Several factors contribute to cake collapse, most of which are linked to temperature control, product formulation, and chamber pressure.

1. Exceeding Collapse Temperature (Tc)

Each formulation has a specific collapse temperature. When the product temperature (Tp) exceeds this limit during primary drying, the structure begins to collapse.

Solution: Follow precise temperature control guidelines during freezing and sublimation. Learn more about temperature control in freeze-drying processes.

2. Improper Freezing or Incomplete Solidification

Inadequate or uneven freezing can lead to soft zones within the product, increasing the chance of collapse during sublimation.

Solution: Ensure consistent freezing below the product’s eutectic point. Refer to Eutectic Temperature in Lyophilization for better formulation handling.

3. High Chamber Pressure During Sublimation

Improper vacuum regulation causes heat to build up, pushing the product temperature above safe limits.

Solution: Regularly verify vacuum performance. Use this detailed vacuum performance verification procedure to ensure optimal freeze-dryer function.

4. Incorrect Shelf Temperature Ramp Rates

Overly rapid heating during primary drying can lead to cake shrinkage or meltback.

Solution: Maintain validated ramp-up profiles. Follow industry best practices from freeze dryer operational qualification protocol.

5. High Concentration of Excipients or Sugars

Certain sugars (e.g., mannitol, sucrose) lower the collapse temperature of the formulation and require precise lyophilization cycle development.

Solution: Conduct pre-formulation studies with proper thermal profiling. Check out lyophilization cycle development guide for safe formulation planning.

🧪 Visual Appearance of a Collapsed Cake

- Shrunken structure: The cake doesn’t fill the vial.

- Meltback effect: Edges appear sticky or glassy.

- Surface defects: rough, wavy, or sunken cake top.

- Sticky texture: Difficult to reconstitute with diluent.

To understand other product defects, refer to this complete guide on defects in lyophilized products.

🚨 Consequences of Cake Collapse

- Rejection of batch during quality checks

- Compromised product stability

- Inaccurate dosing upon reconstitution

- Non-compliance with regulatory visual inspection norms

The issue also impacts packaging and shelf life, further reducing product viability in the pharmaceutical market.

✅ Solutions and Best Practices to Prevent Cake Collapse

✔ 1. Conduct Pre-Study Qualification

Use a pre-study qualification of a thermocouple to monitor internal product temperature precisely.

✔ 2. Implement Real-Time Process Monitoring

Use pressure gauges like the TIM APG100 Active Pirani Gauge for accurate vacuum and pressure tracking.

✔ 3. Optimize Drying Time

Primary drying time must be long enough for full sublimation but short enough to avoid thermal buildup. Refer to dry layer resistance during primary drying to monitor thermal gradients effectively.

✔ 4. Follow Proper Commissioning and Qualification

Get your lyophilizer unit fully commissioned and tested for performance, pressure uniformity, and ramp rates. Read:

✔ 5. Enhance Energy Efficiency in Cycle Design

Balancing energy input with drying time ensures thermal stability throughout the process. Explore this guide to energy efficiency in lyophilization.

🧴 Post-Drying: Check for Structural Integrity

After drying, perform a reconstitution test to confirm cake integrity. Learn how to reconstitute lyophilized drug products and inspect for meltback or solubility issues.

📋 Bonus: Regulatory Focus on Visual Appearance

Regulatory bodies like the FDA, EMA, and WHO emphasize that visual inspection is the first quality gate. Collapsed cakes often lead to batch rejection unless justified by risk assessment and scientific rationale. Ensure compliance with:

- CGMP guidelines for lyophilized product manufacturing

- Regulatory compliance guide for lyophilized products

🧾 Conclusion

Why do lyophilized cakes collapse during freeze-drying? The answer lies in a combination of thermal, pressure, and formulation-related errors. With the right preventive measures—like thermal mapping, qualified equipment, and optimized cycle protocols—this defect can be significantly minimized.

By maintaining strong lyophilized product quality standards, pharmaceutical companies can ensure product stability, compliance, and patient safety. Explore more about applications of freeze-drying in biopharmaceuticals to understand its broader significance.

✅ FAQs – Why Lyophilized Cakes Collapse During Freeze-Drying

Q1. What is cake collapse in lyophilization?

A1. Cake collapse refers to the structural failure of the freeze-dried solid, causing it to appear shrunken, melted, or sticky.

Q2. What are the top reasons for cake collapse during freeze-drying?

A2. Key reasons include exceeding collapse temperature, incomplete freezing, improper vacuum control, and incorrect shelf ramp rates.

Q3. Can cake collapse affect drug stability?

A3. Yes, a collapsed cake can compromise product stability, increase reconstitution time, and lead to regulatory rejection.

Q4. How can I prevent lyophilized cake collapse?

A4. By controlling temperature, validating vacuum systems, optimizing excipient formulation, and using qualified equipment and processes.

Q5. What should be done after cake collapse is observed?

A5. The batch should be inspected. Root cause analysis and equipment qualification, like lyophilizer qualification guidelines, must be carried out before reprocessing.