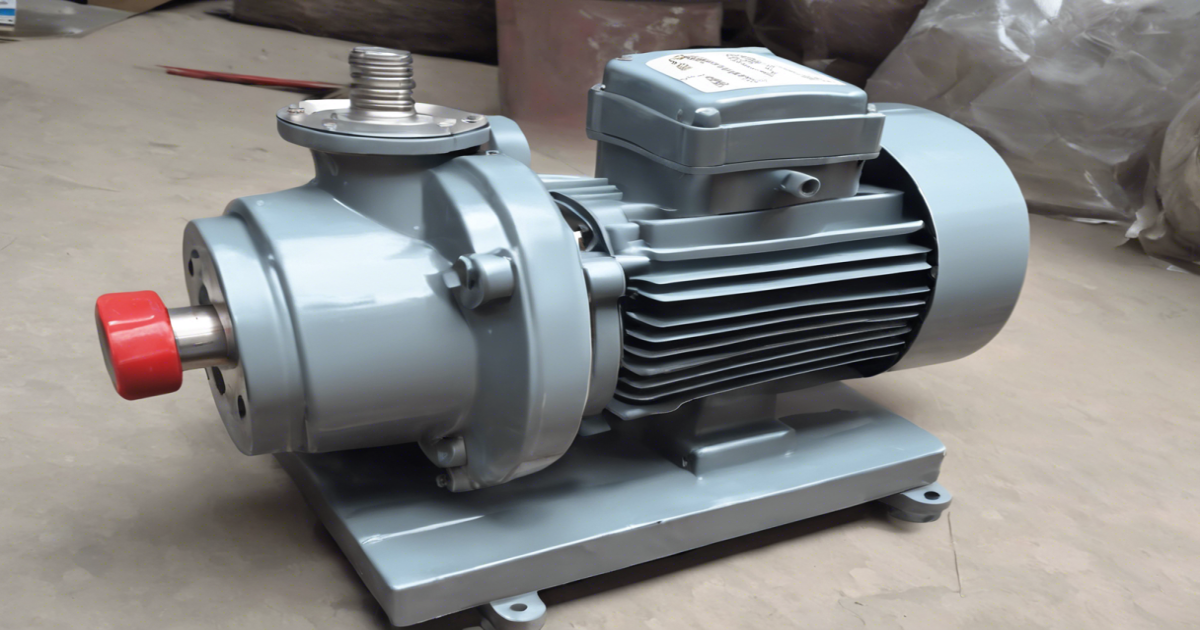

In industrial processes, the Silicon Oil Circulation Pump plays a crucial role in maintaining efficient and stable operations. This pump ensures the continuous flow of silicone oil, which is often used as a heat transfer fluid in various applications.

However, like any other mechanical component, the silicone oil circulation pump can encounter issues that disrupt its operation. In this article, we will delve into the key aspects of silicone oil, the significance of its circulation pump, and the potential failures that may occur in the pump system.

Description:

This article provides an overview of common failures in silicone oil circulation pumps used in industrial systems. It explores the causes of these failures, including issues with motor contactors, protection switches, and temperature monitoring systems. The article also offers troubleshooting tips and preventive measures to ensure the reliable operation of silicone oil pumps, helping to minimize downtime and maintain system efficiency.

What is silicone oil?

Silicone oil is a synthetic compound that consists of long-chain polymers with a silicon-oxygen backbone. Known for its excellent thermal stability, low viscosity, and resistance to oxidation, silicone oil is widely used as a heat transfer fluid in industrial processes, medical devices, cosmetics, and lubricants. Its ability to withstand extreme temperatures makes it an ideal choice for applications where consistent thermal management is required.

🔷 Overview:

This schematic illustrates the silicon oil circulation system in a freeze dryer. Silicon oil is used as a heat transfer fluid to control the shelf temperature during the freeze-drying process. The system ensures accurate heating and cooling of the product shelves via oil flow through heat exchangers, pumps, and sensors.

Failure of a silicone oil pump:

Failures in the silicone oil pump can lead to significant operational challenges. One common failure message is triggered when the related motor contactor is commanded to switch on, but the status “ON” is not reported. This failure can stem from various causes, which are outlined below: This failure message is given when the related motor contactor is commanded on, but the status ON is not reported. The causes for this failure could be:

Causes of Silicone Oil Pump Failure

The motor protection switch is responsible for safeguarding the motor from overload or short circuits. If this switch is tripped or malfunctioning, it can prevent the motor from turning on, leading to a failure in the pump operation.

Coil of the Motor Contactor: The motor contactor is an electrically controlled switch used to start and stop the motor. If the coil within the motor contactor is damaged or faulty, it can result in the motor failing to engage, thereby causing the pump to fail.

Interrupted Control Line to the Motor Contactor: The control line to the motor contactor has been interrupted. The control line delivers signals to the motor contactor to engage the motor. Any interruption in this control line, whether due to a break in the wiring or a loose connection, can lead to the motor failing to start, triggering a failure message.

Silicone Oil Pump Excess Temperature: An excess temperature condition can occur when the motor winding high-temperature switch is activated, causing the pump to shut down to prevent damage. Once the temperature cools and the switch resets to its normal status, the pump will automatically restart.

Causes of Excess Temperature Failure

Excess temperature in the silicone oil pump is a critical issue that can disrupt the entire system. Below are the common causes:

Silicone oil pump excess temperature

This failure message appears when the motor-winding high-temperature switch has switched off the pump. The pump is switched on automatically again when the temperature has cooled down again because the temperature switch has automatically reset to normal status.

The causes of this failure could be

- The connecting line to the switch has been interrupted or the switch is defective

- The flow in the silicone oil circuit is too low

- The excess temperature safety switch is defective

Interrupted or Defective Connecting Line to the Temperature Switch: The temperature switch is responsible for monitoring the motor winding temperature. If the connecting line to this switch is interrupted or if the switch itself is defective, it may not accurately detect the temperature, leading to pump failure.

Low Flow in the Silicone Oil Circuit: Proper flow of silicone oil is essential for effective heat transfer and motor cooling. If the flow rate is too low, it can result in insufficient cooling, causing the motor to overheat and triggering the excess temperature safety switch.

Defective Excess Temperature Safety Switch: The excess temperature safety switch is designed to protect the motor from overheating. If this switch is defective, it may not trigger at the appropriate temperature, leading to potential damage or failure of the pump.

Impact of Silicone Oil Pump Failure on Freeze-Drying

The failure of a silicone oil circulation pump can have a significant impact on freeze-drying processes. Silicone oil is often used as a heat transfer fluid in freeze-drying systems to maintain precise temperature control. If the pump fails, it can lead to several critical issues:

Inconsistent Temperature Control: The primary role of silicone oil in freeze-drying is to regulate the temperature of the shelves where products are placed. A pump failure disrupts the flow of silicone oil, leading to uneven temperature distribution. This can result in incomplete or uneven drying of the product, compromising its quality and efficacy.

Extended Drying Time: Without proper temperature regulation, the freeze-drying process may take longer than expected. This delay can increase operational costs and reduce throughput, affecting overall productivity.

Risk of Product Damage: In freeze-drying, maintaining a consistent low temperature is crucial to preventing product degradation. A pump failure could cause temperature spikes, potentially damaging sensitive products and leading to costly losses.

System Shutdown: In severe cases, a failure in the silicone oil circulation pump could trigger safety mechanisms that shut down the entire freeze-drying system to prevent further damage. This unplanned downtime can result in significant delays and financial losses.

Maintenance and Repair Costs: Addressing the pump failure and any resulting damage to the freeze-drying system can lead to increased maintenance and repair costs. Prolonged or repeated failures may require costly equipment replacements.

In summary, the failure of a silicone oil pump in a freeze-drying system can disrupt temperature control, extend processing times, risk product quality, and lead to costly downtime and repairs. Ensuring the reliability of the pump through regular maintenance is essential for maintaining efficient and effective freeze-drying operations.

Conclusion

The circulation pump for silicone oil is an integral component in maintaining the efficiency and safety of industrial processes. Understanding the potential causes of pump failure, such as issues with the motor contactor, protection switch, or temperature monitoring systems, is essential for preventing downtime and ensuring smooth operations. Regular maintenance and prompt troubleshooting can help mitigate these risks, ensuring the longevity and reliability of the silicone oil pump. This system plays a critical role in maintaining accurate shelf temperatures during the freeze-drying process. Proper functioning of heaters, pumps, valves, and sensors ensures product quality, safety, and process efficiency.

FAQs: Circulation Pump for Silicone Oil

What is the role of the circulation pump for silicone oil?

The circulation pump for silicone oil is responsible for maintaining the continuous flow of silicone oil within an industrial system. It is used as a heat transfer fluid, and the pump ensures that it circulates efficiently to manage temperature and maintain the system’s stability.

What are the common causes of silicone oil pump failure?

Common causes of silicone oil pump failure include issues with the motor protection switch, the coil of the motor contactor, or interruptions in the control line to the motor contactor. Additionally, excess temperature due to low flow or a defective temperature switch can also cause pump failure..

Can a defective excess temperature safety switch cause permanent damage to the pump?

Yes, a defective excess temperature safety switch can lead to permanent damage. If it fails to trigger at the appropriate temperature. This can result in the motor overheating, which may cause severe damage to the pump and other components in the system. Regular inspection and testing of the safety switch are crucial to avoiding such issues.

Why is silicone oil used in industrial applications?

Silicone oil is used in industrial applications due to its excellent thermal stability, low viscosity, and resistance to oxidation. It can withstand extreme temperatures, making it an ideal heat transfer fluid for systems that require consistent temperature control.

What happens if the flow of oil is too low?

If the flow of silicone oil is too low, it can lead to insufficient cooling, causing the motor to overheat. This may trigger the excess temperature safety switch and result in the pump shutting down to prevent damage.

What is the purpose of silicon oil in a freeze dryer?

Silicon oil acts as a heat transfer fluid that helps regulate the temperature of the freeze dryer shelves during freezing and drying phases.

How does the heat exchanger function in this system?

The heat exchanger adjusts the temperature of silicon oil by either cooling it with chilled fluid or maintaining its heat, depending on the process requirement.

What role do temperature sensors play in the freeze dryer?

Temperature sensors monitor the oil temperature at different points (inlet, heat exchanger, etc.) to ensure accurate thermal control throughout the drying cycle.

What happens if the pressure in the system is too high or too low?

Abnormal pressure readings could indicate blockages, leaks, or pump failure, which can disrupt the temperature uniformity and affect product quality.