In the pharmaceutical industry, maintaining leak rate testing of lyophilizers is crucial for ensuring product quality and regulatory compliance. One fundamental aspect of this maintenance is leak rate testing, which evaluates the system’s ability to maintain vacuum pressure. Understanding the formula for conducting leak rate testing is essential for pharmaceutical professionals involved in the operation and maintenance of lyophilizers and freeze dryers. This article delves into the key components of the formula and provides insights into its practical application to optimize system performance and product integrity.

Table of Contents

- Freeze Dryer

- Pharmaceutical Freeze Dryers and Lyophilizers

- Vacuum Integrity

- Leak Testing

- Lyophilization Process

- Lyophilizer & Freeze Dryer Maintenance

- Leak Test Vacuum System

- Leak Test Vacuum Line

- Leak Test Vacuum Pump

- Leak Test Vacuum Seals

- Leak Test Refrigeration System

- Leak Test Condenser

- Leak Test Compressor

- Leak Test: Regulating Valves

- Typical Indicators of In-Leakage

- Door Seals

- Main Vapor Valve Flanges

- Instrumentation Connections

- Thermocouple Feedthroughs

- Relief Valves

- Process Valves

- How to Calculate Leak Test of Lyophilizer

- Acceptance Criteria

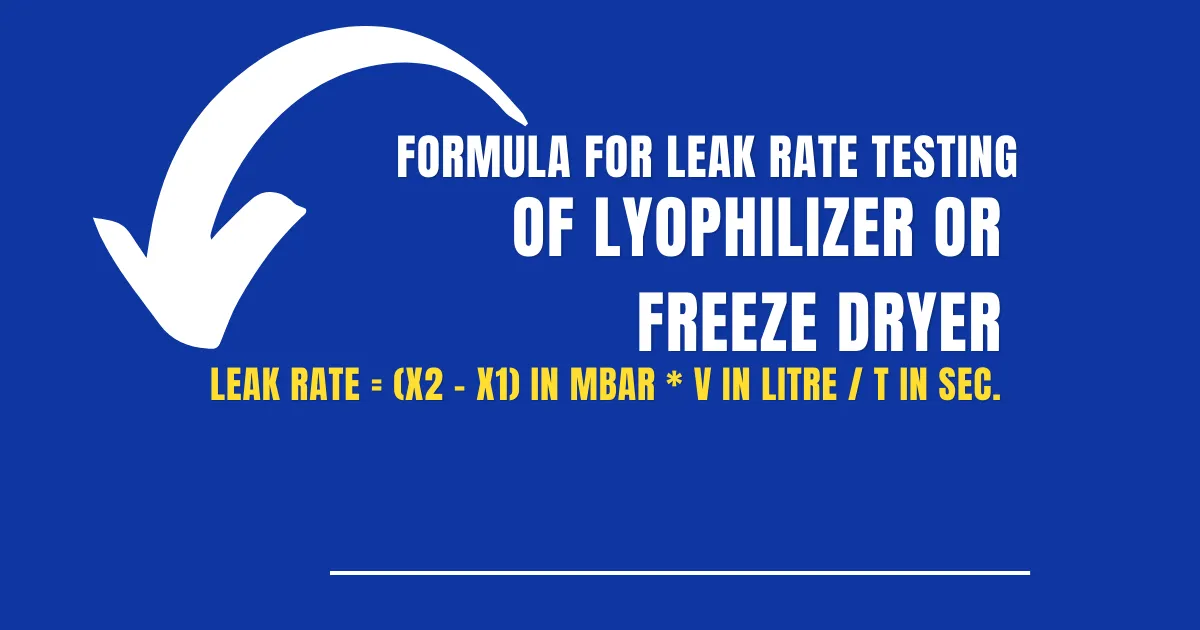

- Formula for Leak Rate Testing

- Understanding Formula Components

- Practical Application of the Formula

- Checks and Precautions

- Conclusion

- FAQs of Leak Rate Testing of Lyophilizer or Freeze Dryer

- Leak Test Rate for Freeze Dryer

- Commonly Used Leakage Tests for Lyophilized Products

- Difference Between Freeze Dryer and Lyophilizer

- Procedure of Leak Test in Pharma

- Formula for Calculating Leak Rate

- Minimum Required Pressures for Compressed Air, Chilled Water, and Nitrogen

Freeze dryer

Freeze drying, also known as lyophilization, is a process increasingly utilized in the pharmaceutical industry to stabilize products that may not maintain their integrity over extended periods in a liquid state. This method involves freezing the product and then subjecting it to a vacuum, removing the frozen solvent (usually water) through sublimation, and leaving behind a solid that retains its properties.

Pharmaceutical freeze dryers and lyophilizers

Lyophilizer & Freeze Dryer Maintenance

- Proper maintenance of lyophilizers and freeze dryers is essential to ensuring their efficiency and reliability. One crucial aspect of maintenance is conducting leak tests on various components to prevent any potential issues. Here’s a breakdown of what needs to be checked:

- Leak Test Vacuum System: Verify the integrity of the vacuum system to ensure it operates correctly.

- Leak Test Vacuum Line: Inspect the vacuum lines for any leaks or damages that may affect their performance.

- Leak Test Vacuum Pump: Check the vacuum pump to ensure it maintains proper suction without any leaks.

- Leak Test Vacuum Seals: Examine the vacuum seals to confirm they are intact and effectively seal the system.

- Leak Test Refrigeration System: Evaluate the refrigeration system to detect any leaks that could affect cooling efficiency.

- Leak Test Condenser: Inspect the condenser for leaks or blockages that may hinder the freeze-drying process.

- Leak Test Compressor: Check the compressor for any leaks or malfunctions that could impact its operation.

- Leak Test: Regulating Valves: Verify the regulating valves are functioning correctly and are not leaking.

Regularly performing these leak tests helps maintain the functionality and integrity of lyophilizers and freeze dryers, ensuring they operate optimally and produce high-quality products consistently.