Step-by-Step Guide to Addressing Excess Pressure Failures

When you encounter an excess pressure failure, it’s crucial to follow a systematic approach to resolve the issue:

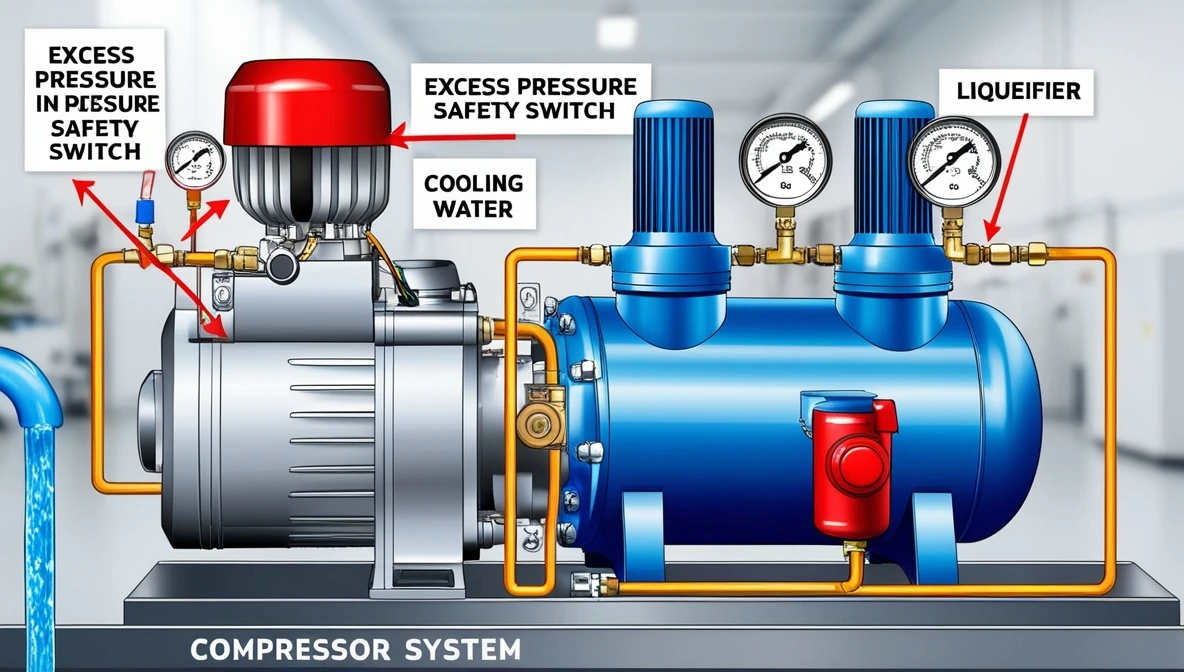

- Identify the Failure: Check the system for any warning messages indicating an excess pressure issue.

- Inspect the Pressure in the Liquefier: If the pressure is too high, investigate the cooling water flow to the liquefier.

- Reset the Pressure Safety Switch: Once the problem is resolved, press the unlocking button on the switch casing to reset the compressor.

Solutions for High Pressure in the Liquefier

To tackle high pressure in the liquefier, you need to ensure that the cooling water flow is optimized. This can be done by:

- Regularly Checking the Cooling System: Ensuring that there’s no blockage or malfunction in the water flow.

- Cleaning and Inspecting the Liquefier: Preventative maintenance is essential to avoid high-pressure issues.

Restarting the Compressor After Excess Pressure Failure

Once the failure has been eliminated, you’ll need to follow these steps:

- Press the unlocking button installed in the switch casing.

- Wait for the designated period before attempting to restart the compressor.

This waiting period is crucial to ensure that the system stabilizes before reactivating the compressor.

Preventative Maintenance for Compressor Systems

Regular maintenance is key to avoiding excess pressure failures in the future. Make it a habit to:

- Inspect Cooling Systems: Check for proper water flow.

- Monitor Safety Switches: Ensure they are functioning properly and replace them if necessary.

The Role of the Pressure Safety Switch in Preventing Damage

The pressure safety switch is an essential component for detecting excess pressure early. By shutting down the compressor when necessary, it prevents severe damage to the system, saving you from costly repairs down the line.

Troubleshooting the Excess Pressure Switch

If you suspect the excess pressure switch isn’t functioning correctly, here’s what to do:

- Test the Switch: Use a multimeter to check if the switch is still operational.

- Replace if Necessary: If the switch is faulty, it should be replaced promptly.

Impact of Excess Pressure on Compressor Efficiency

Excess pressure can significantly impact the compressor’s efficiency. When the system is overloaded with pressure, it has to work harder, leading to more energy consumption and potential long-term damage.

Signs of Compressor Excess Pressure Failure

Look out for these warning signs:

- Unusually high pressure readings

- Frequent shutdowns due to safety switches

- Inefficient cooling or airflow

Avoiding Future Excess Pressure Issues

Preventing excess pressure failures can be achieved by following best practices, such as upgrading to modern pressure switches and ensuring the cooling systems are well-maintained.

Cost Implications of Excess Pressure Failures

Ignoring excess pressure issues can lead to:

- Repair Costs: Replacing damaged components.

- Downtime: The compressor will remain offline until repairs are completed.

Conclusion

Compressor excess pressure is a common yet critical issue that can be managed through regular maintenance, careful monitoring, and timely repairs. By understanding the causes and solutions, you can ensure that your compressor system operates efficiently and reliably.

FAQs

How do you fix excess pressure in compressors?

To fix excess pressure, you need to inspect the liquefier, optimize the cooling water flow, and ensure the pressure switches are functioning properly.

What happens if you ignore excess pressure failures?

Ignoring excess pressure failures can lead to severe system damage, costly repairs, and extended downtime.

How does excess pressure affect compressor lifespan?

Excess pressure can overwork the compressor, leading to increased wear and tear, which shortens its overall lifespan.