Characteristics of the Freeze-Drying Process

Have you ever wondered how your favorite instant coffee or astronaut ice cream is made? The answer lies in a fascinating method called freeze-drying. This process preserves perishable materials, ensuring they last much longer without losing their quality. Let’s dive into the unique characteristics of the freeze-drying process and understand why it’s a game-changer in food preservation and beyond.

What is Freeze-Drying?

Freeze-drying, also known as lyophilization, is a dehydration process used to preserve a wide array of perishable products. Unlike traditional drying methods, freeze-drying involves freezing the product and then reducing the surrounding pressure to allow the frozen water in the product to sublimate directly from the solid phase to the gas phase.

Freeze-Drying Stages:

-

- Sublimation (Freezing)

- Primary Drying

- Secondary Drying

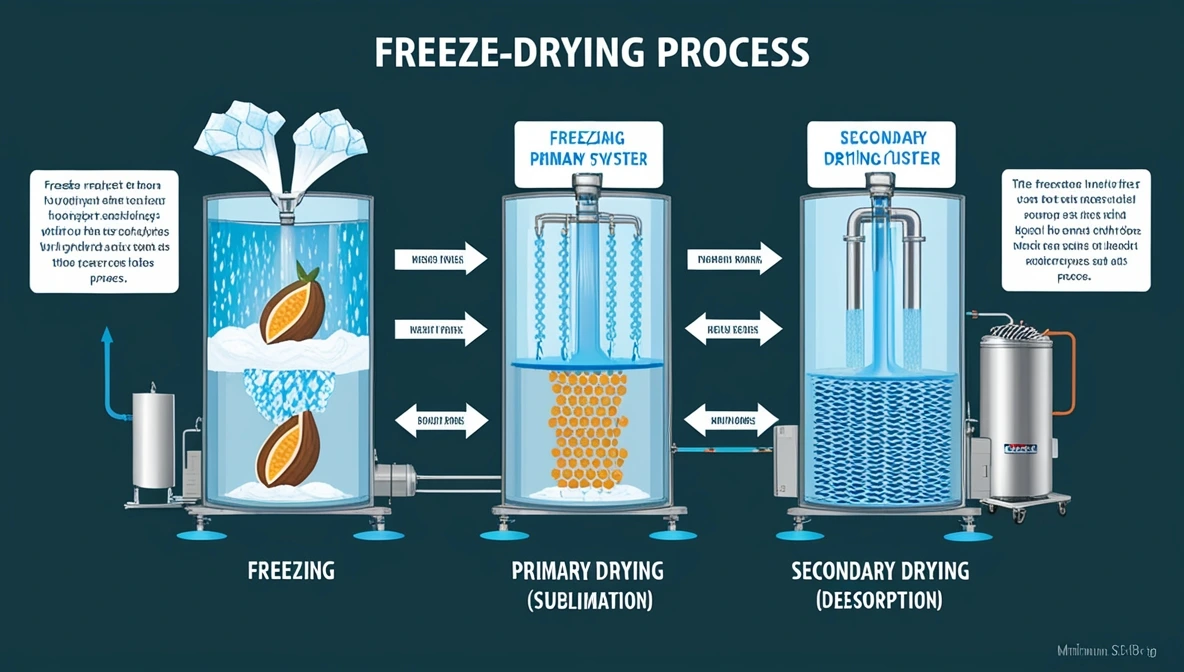

Freezing

The first step in freeze-drying is freezing the product. This phase is crucial because it preserves the product’s structural integrity and prevents ice crystals from damaging the cellular structure. The product is rapidly frozen to ensure that small ice crystals form, maintaining the product’s original texture and appearance.

Primary Drying (Sublimation)

In the primary drying phase, the pressure is lowered and heat is applied to the product. This causes the frozen water to sublimate, meaning it transitions directly from a solid to a vapor without passing through the liquid stage. This stage removes about 95% of the water content from the product.

Secondary Drying (Desorption)

The secondary drying phase aims to remove the unfrozen water molecules that are bound to the material. By gradually raising the temperature, the remaining water is desorbed, resulting in a final product with very low moisture content. This stage ensures that the product is stable and can be stored for long periods.

Advantages of Freeze-Drying

Long Shelf Life

One of the most significant advantages of freeze-drying is the extended shelf life of the products. With the moisture content reduced to minimal levels, freeze-dried products can last for years without the need for refrigeration, making them ideal for long-term storage.

Preservation of Nutritional Value

Freeze-drying preserves the nutritional value of the product better than other drying methods. The process retains the vitamins, minerals, and flavors, ensuring the final product is as close to fresh as possible.

Lightweight and Convenient

The removal of water makes freeze-dried products significantly lighter, which is perfect for activities like backpacking or space travel where weight is a concern. Additionally, these products are easy to rehydrate and use.

Applications of Freeze-Drying

Food Industry

Freeze-drying is extensively used in the food industry to preserve fruits, vegetables, meats, and instant meals. It ensures that the food retains its taste, texture, and nutritional content, providing consumers with a high-quality product.

Pharmaceuticals

In the pharmaceutical industry, freeze-drying is used to preserve antibiotics, vaccines, and other biological materials. The process ensures the stability and efficacy of these sensitive products.

Biotechnology

Biotechnology applications include the preservation of enzymes, microorganisms, and cell cultures. Freeze-drying helps maintain the viability and functionality of these biological materials over extended periods.

Document Preservation

Freeze-drying is also employed in the preservation of important documents and books that have been water-damaged. The process effectively removes moisture without causing additional damage to the delicate paper.

Challenges in Freeze-Drying

High Cost

One of the main drawbacks of freeze-drying is the high cost associated with the process. The equipment and energy required are significant, making it more expensive than other drying methods.

Time-Consuming

Freeze-drying is a slow process, often taking several hours to complete. This extended time frame can be a limiting factor, especially in high-demand situations.

Technical Complexity

The freeze-drying process is technically complex and requires precise control of temperature and pressure. This complexity necessitates skilled operators and robust equipment to ensure consistent results.

Innovations in Freeze-Drying

Energy Efficiency

Recent advancements aim to make freeze-drying more energy-efficient. Innovations include improved vacuum pumps and heat transfer methods that reduce energy consumption and operational costs.

Speed Enhancements

New technologies are being developed to shorten the freeze-drying process without compromising quality. These include advanced freezing techniques and optimized drying cycles.

Automation

Automation is playing a significant role in modern freeze-drying. Automated systems ensure precision and consistency, reducing the need for manual intervention and minimizing errors.

Six Main Physical Phenomena in Freeze-Drying:

-

- Phase transition of water into ice.

- Ice-to-vapor phase transition.

- Desorption of water molecules from material structures.

- Achieving sufficiently low pressure.

- Re-sublimation of water vapor on the condenser surface.

- Removal of the ice layer from the condenser.

Important Factors:

-

- Balance the heat supply to avoid slow processes or overheating.

- Monitor the temperature to prevent exceeding cryoscopic or glass transition temperatures.

- Low-temperature maintenance ensures a balanced heat supply and sublimation rate.

Freezing Process:

-

- Freezing is critical for solid (fruits, vegetables) and liquid products (coffee, juices).

- Benefits of freezing include immobilizing ingredients, limiting chemical and biological changes, creating ice crystal structure, and stiffening product structure.

Freezing Rate:

-

- Freezing rate affects ice crystal size and product properties.

- Optimal freezing varies by material type (solution, suspension, or biological).

- Large ice crystals reduce mass transfer resistance in primary drying; smaller crystals are better for secondary drying.

- Quick freezing of biological materials is necessary to prevent cell damage.

New Technologies:

-

- Spray-Freezing into Liquid (SFL): Creates ice spheres for a porous bed, enhancing heat and mass transfer.

- Control Over Residual Moisture, Density, and Particle Size: SFL allows for high control over these parameters.

- Radiant Heating: Essential for SFL due to limited heat conduction through small particles.

Conclusion of Characteristics of the Freeze-Drying Process

Freeze-drying is an innovative and versatile method for preserving a wide range of perishable products. Despite its high cost and complexity, the benefits of extended shelf life, preserved nutritional value, and lightweight convenience make it an invaluable process in various industries. Continuous advancements in technology are making freeze-drying more efficient and accessible, ensuring its ongoing importance in food preservation, pharmaceuticals, biotechnology, and more.

FAQs on Characteristics of the Freeze-Drying Process

Characteristics of Freeze-Dried Products

Freeze-dried products exhibit several unique characteristics that distinguish them from products preserved using other methods:

- High Porosity and Light Weight: Due to the sublimation process, freeze-dried products retain a porous structure, making them lightweight.

- Retained Nutritional and Bioactive Compounds: The low-temperature drying process helps preserve vitamins, antioxidants, and other sensitive bioactive compounds.

- Extended Shelf Life: Reduced moisture content leads to a significant extension in shelf life without the need for refrigeration.

- Texture Preservation: Freeze-drying maintains the original texture of the product, which is crucial for consumer acceptance, especially in food products.

- Enhanced Rehydration Ability: Freeze-dried products can be quickly and easily rehydrated, restoring their original properties more effectively than products dried using other methods.

- Minimal Shrinkage: The process minimizes shrinkage, helping maintain the original shape and size of the product.

Features of a Freeze Dryer

Freeze dryers, also known as lyophilizers, come equipped with various features to facilitate the freeze-drying process effectively:

- Freezing Chamber: This is where the initial freezing of the product takes place, solidifying the water content.

- Vacuum System: Essential for reducing pressure during the primary drying phase, allowing ice to sublimate directly into vapor.

- Heating Shelves: Provide controlled heat to the product during primary and secondary drying stages to facilitate sublimation and desorption.

- Condenser: Captures and condenses the vaporized water, preventing it from returning to the product.

- Sensors and Controls: Advanced sensors monitor temperature, pressure, and moisture levels, ensuring optimal conditions throughout the process.

- Chamber Design: The design of the chamber is crucial for uniform drying, with features that allow for even heat distribution and efficient vapor removal.

Principles of Freeze-Drying Process

The freeze-drying process is based on the principle of sublimation, where water transitions directly from a solid (ice) to a gas (vapor) without passing through the liquid phase. The process can be broken down into three main stages:

- Freezing: The product is frozen, and the water content is solidified into ice crystals. This step is critical, as the size and distribution of the ice crystals influence the quality of the final product.

- Primary Drying (Sublimation): Under reduced pressure, heat is applied to the frozen product, causing the ice to sublimate. The vapor is then removed via a vacuum system and condensed.

- Secondary Drying (Desorption): Any remaining unfrozen water molecules are removed by further heating the product. This reduces the residual moisture content to safe levels, ensuring stability and extended shelf life.

Objectives Behind Freeze-Drying

The primary objectives behind employing freeze-drying as a preservation method are:

- Preservation of Bioactive Compounds: To maintain the nutritional and bioactive integrity of the product, ensuring it retains its therapeutic or nutritional benefits.

- Enhanced Stability and Shelf Life: By significantly reducing moisture content, freeze-drying prevents microbial growth and chemical degradation, extending the product’s shelf life.

- Retaining Product Quality: To preserve the original texture, color, flavor, and overall sensory attributes, which are crucial for consumer acceptance.

- Facilitating Easy Rehydration: To enable the product to be easily and quickly rehydrated to its original state, maintaining its structural and functional properties.

- Minimizing Additive Use: To avoid the need for chemical preservatives or additives, offer a more natural and clean-label product.