What is the purpose of a freezer dryer?, Ever wondered what a freeze dryer does and why it’s so essential in various fields? Freeze dryers, though not a household name for many, play a crucial role in preserving food, pharmaceuticals, and even biological samples. Understanding the purpose of a freezer dryer and the functionality of these machines can offer insights into their importance in our daily lives.

The initial significant application of freeze-drying technology was during World War II, used for transporting penicillin, blood, and serum. Since then, lyophilization technology has advanced significantly and is now utilized across various industries for numerous purposes. Modern drying methods have become integral to the development of many pharmaceuticals and are widely used in biological and environmental research, often employing laboratory freeze dryers.

Table of Contents

ToggleThe Science Behind Freeze Drying

How Freeze Drying Works

Freeze drying, also known as lyophilization, is a process that removes moisture from a product after it is frozen and placed under a vacuum. This process allows the ice to change directly from solid to vapor without passing through a liquid phase, a phenomenon known as sublimation.

Key Stages of Freeze-Drying

Freezing: The product is frozen to solidify the water content.

- Crucial phase of the freeze-drying procedure.

- The sample material must be cooled to at least its melting point.

- Ensures thorough freezing for successful sublimation.

- Prevents evaporation, which hinders preservation quality.

Primary Drying (Sublimation): Under a vacuum, the ice sublimates, removing most of the water.

- The primary drying process starts once the freeze dryer and vacuum pump are running.

- Low pressure causes evaporative cooling, releasing heat to speed up drying.

- Approximately 93% of the sample’s water is sublimated during this phase.

- The duration of this phase can last several days, depending on the heat input and sample type.

Secondary Drying (Desorption): Remaining moisture is removed at higher temperatures.

- Releases water molecules attached to the specimen.

- It involves adding more heat to remove extra moisture.

- Reduces the overall moisture level to roughly 2%.

- Prepares samples for long-term storage and preservation.

Summary:

- The freezing of the product, most often under atmospheric pressure.

- Primary drying—(proper freeze-drying)—ice sublimation, most often at reduced pressure.

- Secondary drying—(desorption drying)—drying the product to the required final humidity.

Historical Background of Freeze Drying

Early Uses of Freeze-Drying

The modern freeze-drying process was developed during World War II to preserve blood plasma and penicillin for soldiers.

- Jacques-Arsene d’Arsonval invented freeze drying at the College de France in Paris in 1906.

- During World War II, freeze-drying became widely used for preserving blood serum.

- Since then, freeze-drying food has emerged as a critical method for preserving heat-sensitive biological materials.

Evolution Over the Years

From its early applications, freeze drying has evolved into a sophisticated technology used in various industries, driven by advancements in equipment and process understanding.

- Freeze drying has evolved from rudimentary beginnings to a sophisticated technology utilized across multiple industries.

- Advancements in equipment design have significantly enhanced the efficiency and capabilities of freeze-drying processes.

- Improved understanding of the freeze-drying process has led to more precise control over variables like temperature and pressure.

- The technology’s applications have expanded beyond its initial uses in food and pharmaceuticals to include biotechnology and material sciences.

- Ongoing research and development continue to push the boundaries of freeze drying, explore new applications, and improve sustainability.

Summary: Freeze drying, developed by Jacques-Arsene d’Arsonval in 1906, initially gained prominence during World War II for preserving blood serum.

Types of Freeze Dryers

Laboratory Freeze Dryers

Used for research and development, these are designed to handle small batches and are essential in pharmaceutical and biological research labs.

- Laboratory freeze dryers are essential tools in scientific research and development settings.

- They are designed to handle small to medium-sized batches of samples.

- These units provide precise control over temperature and pressure conditions during the drying process.

- Laboratory freeze dryers are used extensively in pharmaceutical, biotechnology, and academic research laboratories.

- They enable the preservation of biological samples and pharmaceutical products with minimal degradation of their properties.

Summary: Laboratory freeze dryers are vital for precise sample preservation in scientific research, ensuring minimal degradation of biological and pharmaceutical materials.

Industrial Freeze Dryers

These large-scale machines are used in the food industry and pharmaceutical manufacturing and are capable of processing large quantities efficiently.

- Industrial freeze dryers are designed for large-scale production and processing.

- They can handle significant quantities of materials in each batch.

- These dryers feature robust construction to withstand continuous operation.

- Industrial freeze dryers offer advanced control systems for precise monitoring of temperature, pressure, and cycle times.

- They are used extensively in food manufacturing, pharmaceutical production, and chemical industries for efficient and reliable preservation of products

Summary: Industrial freeze dryers are essential in large-scale operations across food, pharmaceutical, and chemical industries

Home Freeze Dryers

Gaining popularity among survivalists and home gardening enthusiasts, these smaller units allow for personal food preservation.

- Home freeze dryers are becoming increasingly popular among survivalists and home gardening enthusiasts.

- They are compact and designed for personal use, fitting well in home environments.

- These units allow individuals to preserve a variety of foods at home, including fruits, vegetables, and meats.

- Home freezer dryers operate on a smaller scale compared to industrial or laboratory models.

- They offer convenience by allowing users to preserve seasonal produce or leftovers.

- Preservation through freeze drying retains food nutrients better than traditional methods like canning or drying.

- These dryers typically use a combination of freezing and vacuum technology to remove moisture.

- They are user-friendly and often equipped with automated features for ease of operation.

- Home freezers contribute to reducing food waste by extending the shelf life of perishable items.

- Cost-effective over time, they provide long-term storage solutions for emergency preparedness or everyday use.

Summary: Home freeze dryers are compact appliances increasingly favored by survivalists and home gardeners. They allow for easy preservation of a variety of foods like fruits, vegetables, and meats at home

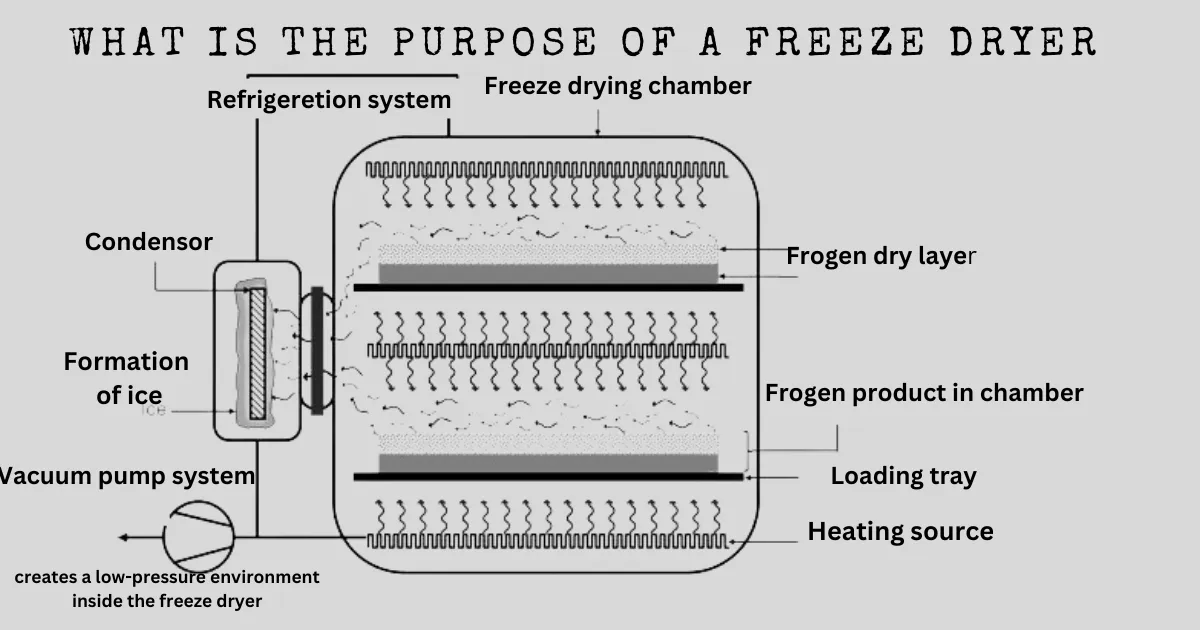

Components of a Freeze Dryer

Main Chamber

The chamber is where the product is placed for freezing and drying. The main components include: Chamber: This is where the product is placed and is typically maintained at a low pressure to facilitate sublimation. Shelves: They form the base for the product, allowing it to rest and be temperature-controlled, which is essential for managing the freezing and drying processes

Vacuum System

Essential for creating the low-pressure environment required for sublimation.The vacuum system is crucial because it creates a low-pressure environment inside the freeze dryer. This low-pressure environment is necessary for sublimation to occur effectively. Sublimation is the process where ice directly transitions from solid to vapor without passing through the liquid phase. By reducing the pressure in the chamber, the vacuum system allows this transition to happen at lower temperatures than it would under normal atmospheric conditions, preserving the integrity and properties of the product being freeze-dried.

Summary: The vacuum system in a freeze dryer is essential as it creates a low-pressure environment crucial for sublimation. Sublimation is the process where ice transforms directly into vapor without becoming liquid first.

Condenser

Captures the vaporized moisture from the product. The condenser in a freeze dryer is responsible for capturing the vaporized moisture that is released from the product during the freeze-drying process. As the product undergoes sublimation (where water transitions directly from solid to vapor), the condenser cools down these vapor molecules. This cooling causes the vapor to condense back into liquid form on the surface of the condenser. The condensed water is then collected and removed from the system, preventing it from re-entering the product chamber. This process helps maintain the low-pressure environment necessary for effective freeze drying and ensures that the product retains its desired properties without excess moisture.

Summary: The condenser in a freeze dryer plays a crucial role by capturing vaporized moisture from the product during the freeze-drying process. As the product undergoes sublimation, where water transitions directly from solid to vapor, the condenser cools the vapor, causing it to condense back into liquid form.

Control System

Monitors and controls the temperature, pressure, and duration of the freeze-drying process.

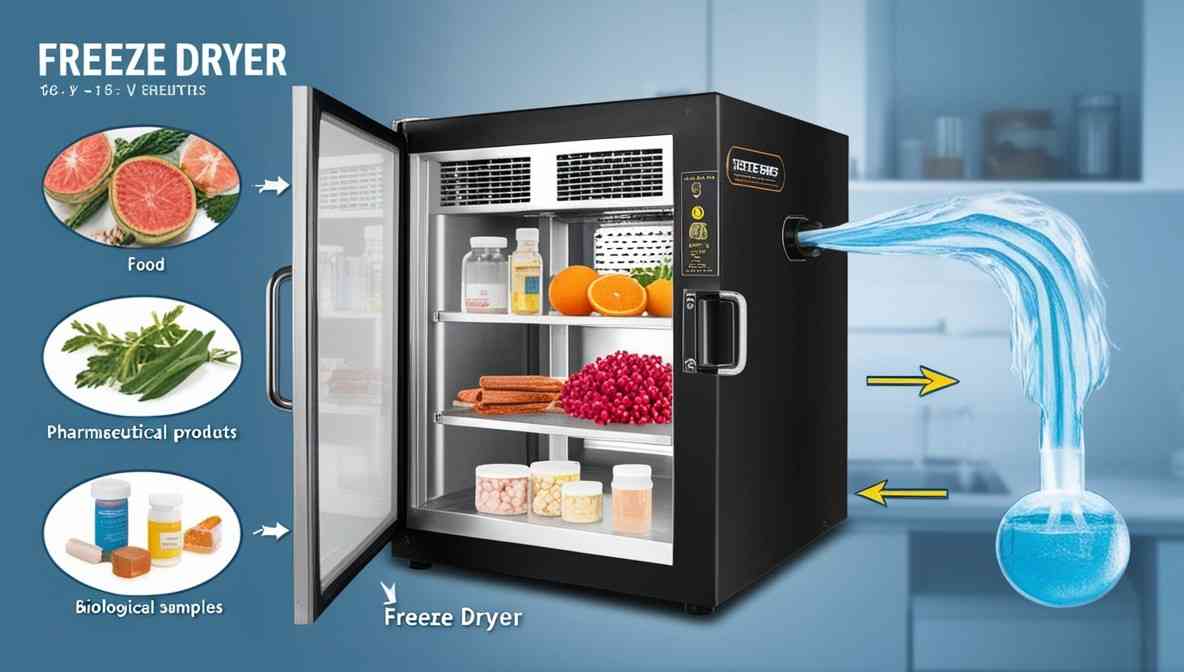

Applications of Freeze Dryers

Food Industry

Freeze dryers preserve the nutritional value, texture, and flavor of food, making them popular for producing high-quality dehydrated foods.

Pharmaceutical Industry: Used to stabilize and preserve medications, especially biologics and vaccines, ensuring they remain effective over time.

Biological Research: Essential for preserving biological samples, such as tissues and microorganisms, without damaging their structural integrity.

Personal Use: Increasingly used by individuals for food preservation, especially among those preparing for emergencies or looking to reduce food waste,

Benefits of Freeze Drying

Preservation of Nutritional Value: Freeze drying retains most of the nutrients in food, unlike other preservation methods that can degrade nutritional content.

Extended Shelf Life: Products can remain preserved for years without the need for refrigeration, making them perfect for long-term storage.

Lightweight and convenient storage: With the moisture removed, freeze-dried products are significantly lighter and easier to store and transport.

Comparing Freeze-Drying to Other Preservation Methods

- Freeze Drying vs. Dehydration: Freeze drying preserves more nutrients and flavor compared to traditional dehydration, which uses heat.

- Canning vs Freeze Drying : Canning involves heat, which can alter the taste and nutritional value of food. Whereas freeze-drying does not.

- Freeze Drying vs. Freezing: Frozen foods require constant refrigeration and can lose quality over time due to freezer burn, unlike freeze-dried foods.

Challenges and Limitations of Freeze-Drying

- Cost Factors: Freeze dryers are expensive to purchase and operate, making them a significant investment.

- Time-Consuming Process: The freeze-drying process can take several hours to days, depending on the product and amount being processed.

- Technical expertise is required: operating and maintaining a freezer requires specialized knowledge, which can be a barrier for some users.

Innovations in Freeze-Drying Technology

Advances in Equipment Design

Modern freeze dryers are becoming more efficient, with better temperature and pressure control systems.

Automation and Control Improvements

Automated systems allow for precise control over the freeze-drying process, reducing the need for manual intervention.

Sustainable Practices

New technologies focus on energy efficiency and reducing the environmental impact of freeze drying.

How to Choose the Right Freeze Dryer

Assessing Your Needs

Determine what you plan to freeze dry, the volume, and the frequency of use to choose the appropriate model.

Budget Considerations

Consider both the initial purchase cost and ongoing operational costs when selecting a freezer.

Technical Specifications

Look at the machine’s capacity, temperature range, and vacuum strength to ensure it meets your requirements.

Freeze-drying at Home

DIY Freeze Drying Techniques

While professional equipment is ideal, some DIY methods involve using household freezers and vacuum chambers, though results may vary.

Safety Tips and Best Practices

Ensure food is properly prepared and handled to prevent contamination. Follow the manufacturer’s guidelines for operating home freezer dryers.

Maintenance and Care for Freeze Dryers

- Regular Cleaning and Upkeep: Clean the chamber and components regularly to prevent contamination and ensure efficient operation.

- Troubleshooting Common Issues: Familiarize yourself with common problems like vacuum leaks or inadequate drying and how to address them.

- Extending the Lifespan of Your Freeze Dryer: Regular maintenance and proper use can significantly extend the lifespan of your freezer, protecting your investment.

Future Trends in Freeze-Drying

Emerging Technologies: Innovations, such as improved vacuum pumps and advanced control systems, are on the horizon.

Potential New Applications: Freeze drying is expanding into new fields like 3D printing of biological tissues and advanced material science.

Market growth predictions: The freeze-drying market is expected to grow, driven by increased demand for preserved foods and pharmaceuticals.

Conclusion of Purpose of Freeze Dryer

In conclusion, freeze drying stands as a crucial and versatile preservation method with wide-ranging benefits across diverse industries. Whether extending the shelf life of food, safeguarding delicate pharmaceuticals, or enabling pioneering research, freeze dryers play an indispensable role. Their ability to retain nutritional integrity and product quality, coupled with advancements in technology and applications, underscores their importance in modern society.

FAQs on Purpose of Freeze Dryer

What is the objective of a freezer dryer?

The objective of a freeze dryer is to remove moisture from products while preserving their structure and properties through sublimation, thereby extending shelf life and maintaining quality.

What is freeze-drying used for?

Freeze drying is used to preserve a wide range of products, such as food, pharmaceuticals, biological samples, and delicate materials, by removing moisture under low temperatures and vacuum conditions.

What is the principle of a freeze dryer?

The principle of a freeze dryer involves freezing the product, reducing the surrounding pressure to induce sublimation (a direct transition from solid to vapor), and then removing the vaporized moisture using a condenser, preserving the product’s integrity.

What is a lyophilizer freeze dryer used for?

A lyophilizer freeze dryer is used primarily for preserving perishable items like food, pharmaceuticals, and biological samples. It maintains the quality, nutritional value, and shelf stability of these materials by removing moisture under controlled conditions.