Introduction: The Evolution of Lyophilization 4.0 (Smart Freeze Drying)

Lyophilization 4.0 (Smart Freeze Drying) marks a revolutionary leap in pharmaceutical manufacturing by combining Industry 4.0 technologies, IoT sensors, and predictive maintenance within modern freeze-drying systems. This new era of digital lyophilization not only boosts process reliability and efficiency but also ensures data-driven decision-making throughout the freeze-drying lifecycle.

In traditional lyophilization, critical parameters such as shelf temperature, chamber pressure, and condenser performance were manually monitored. However, with the rise of Lyophilization 4.0, these processes are now controlled by interconnected devices, AI-based algorithms, and cloud analytics, enabling real-time insights and proactive maintenance.

1. Understanding the Concept of Lyophilization 4.0

1.1 What Is Lyophilization 4.0?

Lyophilization 4.0 refers to the digital transformation of freeze-drying systems by incorporating smart technologies aligned with the principles of Industry 4.0. These include automation, connectivity, advanced data analytics, and machine learning, designed to enhance control, minimize human error, and optimize production outcomes.

This approach is crucial for pharmaceutical and biotech industries where product quality, sterility, and reproducibility are vital. As explained in Freeze-Drying for Cell and Gene Therapy, the stability of biologics and advanced therapies depends heavily on precision drying and accurate process monitoring—both achievable through digital lyophilization systems.

2. Industry 4.0 Integration in Smart Freeze Drying

2.1 Automation and Digital Control

Industry 4.0 integration has redefined the way freeze-drying systems operate. Automated systems now manage complex tasks such as:

- Chamber pressure regulation

- Shelf temperature mapping

- Ice condenser capacity monitoring

- Product temperature optimization

These automated loops are supported by real-time feedback control, ensuring consistent drying outcomes while minimizing operator intervention.

To achieve regulatory compliance, digital monitoring aligns with GMP Freeze-Drying Guidelines and enhances traceability by maintaining detailed electronic batch records (EBR).

2.2 Real-Time Data Connectivity

Modern lyophilizers are equipped with Industrial Internet of Things (IIoT) capabilities. This allows sensors, valves, and compressors to share live operational data through secure cloud networks. Engineers can visualize process trends, deviations, and efficiency reports remotely, enabling predictive analytics and timely interventions.

Such data-driven insights are crucial for maintaining system efficiency as described in Lyophilization Process Efficiency: Best Practices.

3. Role of IoT Sensors in Lyophilization 4.0

3.1 Smart Sensor Integration

IoT sensors act as the “digital eyes” and “ears” of smart freeze dryers. They continuously monitor parameters like:

- Chamber pressure

- Condenser temperature

- Shelf heating uniformity

- Residual moisture content

- Vacuum stability

Through this interconnected network, any variation in parameters is detected instantly, improving product uniformity and batch reproducibility.

3.2 Data Analytics and Predictive Insights

IoT sensors generate vast amounts of process data. This data is analyzed using AI models to predict failures, optimize parameters, and recommend maintenance schedules. For example, temperature or vacuum fluctuations detected early can prevent defects such as meltback or collapsed cakes, detailed in Meltback Defect in Lyophilized Cake: Causes and Solutions.

4. Predictive Maintenance: The Core of Smart Freeze Drying

4.1 From Reactive to Predictive Systems

Traditionally, maintenance followed a reactive model—components were replaced after failure. In Lyophilization 4.0, predictive maintenance uses sensor data, vibration analysis, and AI algorithms to forecast failures before they occur.

This predictive approach:

- Extends equipment lifespan

- Reduces unplanned downtime

- Minimizes production losses

- Enhances operational efficiency

4.2 Predictive Models in Action

For example, the compressor’s performance can be continuously monitored to detect abnormal patterns, as seen in Refrigerating Compressor Failures in Freeze-Drying Processes. Predictive analytics identifies deviations early, allowing for preemptive maintenance instead of costly repairs.

5. Process Analytical Technology (PAT) and AI Integration

5.1 PAT for Enhanced Process Understanding

Process Analytical Technology (PAT) is an essential part of Lyophilization 4.0. PAT tools collect and analyze process data in real time, ensuring each phase—from freezing to secondary drying—is optimized.

You can explore its detailed application in PAT in Freeze-Drying.

5.2 AI Monitoring and Defect Prevention

Artificial Intelligence enhances PAT by learning from historical data. AI algorithms detect subtle process deviations that may lead to quality defects.

In Freeze-Drying AI Monitoring: Smarter Control and Defect Prevention, AI is shown to prevent critical defects like vial fogging or partial collapse by adjusting process parameters autonomously.

6. Continuous and Autonomous Freeze-Drying

6.1 Transition to Continuous Freeze-Drying

Continuous processing is a defining feature of Lyophilization 4.0. Unlike batch systems, continuous freeze-drying maintains a steady flow of product through connected chambers, improving throughput and consistency.

For more insights, refer to Continuous Freeze-Drying Process in Pharmaceuticals.

6.2 Autonomous Control and Learning

Through IoT integration, smart dryers can self-adjust temperature profiles, chamber pressure, and condenser loads based on product feedback. Machine learning helps fine-tune cycles for diverse formulations—significantly improving energy efficiency and yield.

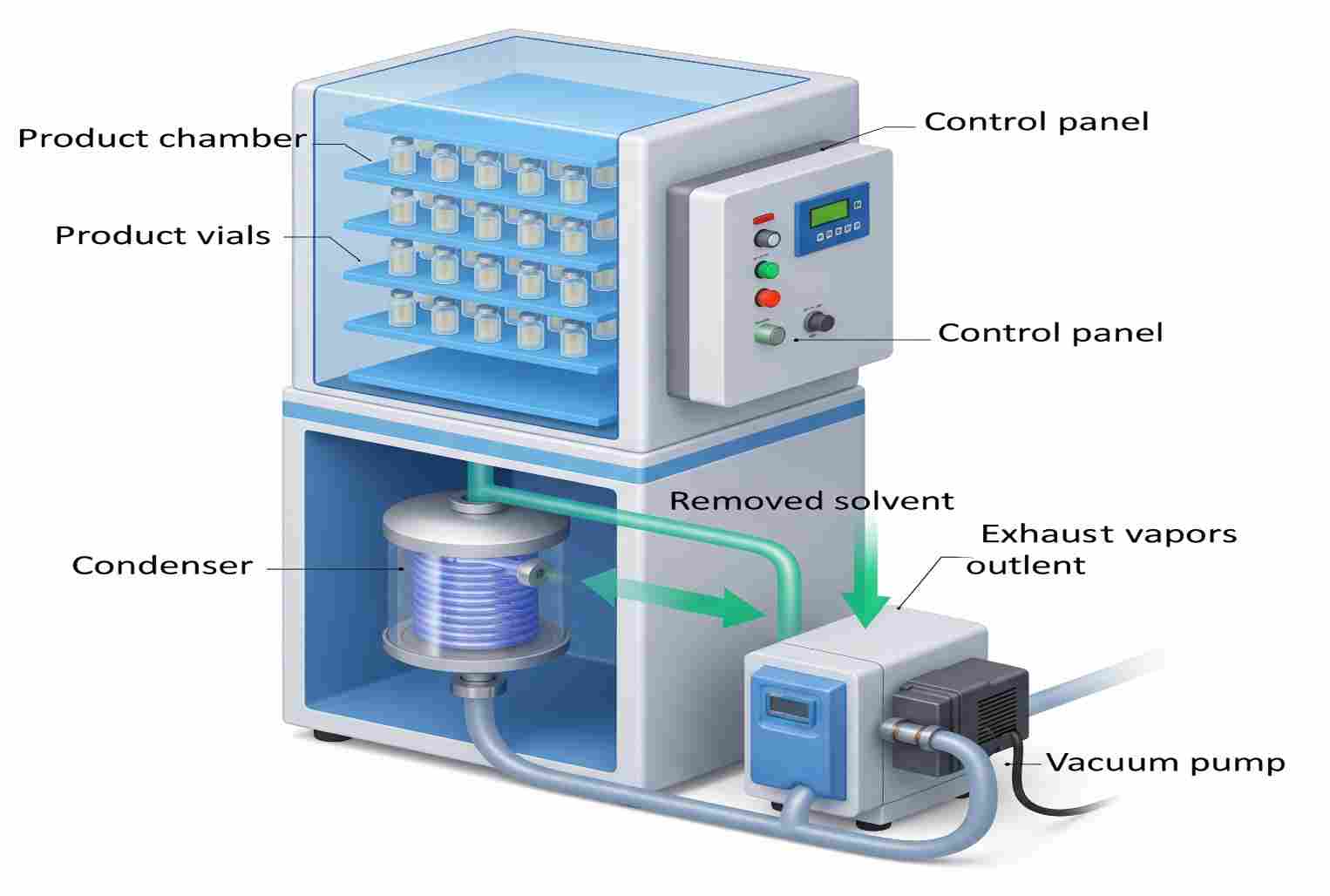

7. Construction and Design in Lyophilization 4.0

7.1 Smart System Architecture

The structural design of modern freeze dryers includes embedded sensors and digital controllers for real-time diagnostics.

A deeper understanding can be gained from Construction of Freeze Dryer.

7.2 Energy and Media Optimization

Smart freeze dryers employ algorithms that regulate heating and cooling media effectively. Studies such as Heating Media Control in Lyophilization and Cooling Water Regulation in Freeze Dryers highlight how digital regulation minimizes energy waste and ensures uniform drying performance.

8. Data Integrity, Compliance, and Validation

8.1 GMP and 21 CFR Part 11 Integration

Digital lyophilization systems automatically record all critical process parameters, complying with GMP and FDA 21 CFR Part 11 requirements. Data encryption and electronic signatures maintain data integrity and audit readiness.

For detailed compliance aspects, explore GMP Requirements for Freeze Drying.

8.2 Validation and Qualification

Each IoT-enabled component undergoes validation testing to ensure operational reliability. Refer to Lyophilizer Qualification Guidelines for best practices in qualifying smart freeze dryers.

9. Benefits of Lyophilization 4.0

- Enhanced Process Control: Real-time monitoring of every parameter.

- Reduced Downtime: Predictive maintenance prevents unexpected halts.

- Improved Product Quality: AI ensures consistent temperature and pressure control.

- Regulatory Compliance: Automated documentation ensures traceability.

- Energy Efficiency: Smart regulation minimizes operational costs.

10. Future of Lyophilization 4.0

The future of lyophilization lies in self-learning dryers, capable of independently adapting to product behavior and environmental changes. Advanced cloud integration, robotics, and digital twins will further transform this field, ensuring that each batch meets exact quality standards without manual intervention.

As Lyophilization 4.0 (Smart Freeze Drying) evolves, it will continue shaping the next generation of pharmaceutical manufacturing, making processes more reliable, sustainable, and intelligent.

Conclusion Of Smart Lyophilization 4.0

Lyophilization 4.0 (Smart Freeze Drying) symbolizes the fusion of innovation and precision in the world of pharmaceutical drying technology. By merging Industry 4.0 principles, IoT connectivity, and predictive maintenance, it delivers a smarter, safer, and more sustainable approach to lyophilization.

This transformation not only enhances production efficiency but also strengthens product reliability and compliance—ushering in a future where digital lyophilization systems think, learn, and adapt autonomously.

Frequently Asked Questions (FAQs) OF Smart Lyophilization 4.0

What is Lyophilization 4.0?

Lyophilization 4.0 refers to the integration of Industry 4.0 technologies like IoT, AI, and automation into freeze-drying systems for smarter control and predictive maintenance.

How does Industry 4.0 improve freeze drying?

Industry 4.0 introduces digital monitoring, data analytics, and automated control, which increase process efficiency and product quality.

What role do IoT sensors play in Lyophilization 4.0?

IoT sensors collect real-time data on temperature, pressure, and vacuum conditions, ensuring consistent product performance.

What is predictive maintenance in smart freeze drying?

Predictive maintenance uses data from sensors to predict equipment failure, preventing downtime and optimizing system reliability.

How does AI enhance freeze-drying operations?

AI analyzes historical and live data to detect deviations early and automatically adjust process parameters for quality consistency.

What are the advantages of continuous freeze drying?

Continuous systems improve throughput, maintain consistency, and reduce energy consumption compared to batch operations.

Is Lyophilization 4.0 compliant with GMP standards?

Yes, digital systems in Lyophilization 4.0 comply with GMP and FDA 21 CFR Part 11, ensuring full traceability and data integrity.

Can smart freeze dryers reduce product defects?

Absolutely. Through AI and PAT tools, smart systems detect and prevent common defects such as meltback and vial collapse.

What industries benefit most from Lyophilization 4.0?

Pharmaceuticals, biotechnology, food preservation, and cell therapy manufacturing gain the most from digital lyophilization advancements.

What is the future of Lyophilization 4.0?

The future involves autonomous systems with AI-driven learning, predictive modeling, and real-time adaptive control for unmatched precision.