Freeze-drying, or lyophilization, is widely used to preserve sensitive pharmaceutical and biotechnological products. A common challenge during this process is the RAMP step extension in freeze-drying, where the freezing phase takes longer than expected due to temperature or pressure fluctuations. This step, which controls shelf cooling, is essential for ensuring uniform product freezing.

In some cases, the system may fail to reach the target freezing temperature within the expected time due to factors such as compressor inefficiency, sensor errors, or pressure imbalance. This results in a RAMP step extension in freeze-drying, which can lead to longer cycle times and potential impact on product quality.

A real-world example involved an attempt to drop the temperature from 5.0°C to -48.0°C, which extended the freezing duration from the expected 120 minutes to 200 minutes. In this article, we will explore the reasons behind this delay, the risks it poses to the product, and the appropriate troubleshooting measures to resolve the issue efficiently.

🔗 Related: Freeze Drying Process Steps Explained Clearly

Table of Contents

ToggleDescription of the Incident

During a routine freeze-drying cycle, the freezing temperature was programmed to drop from 5.0°C to -48.0°C. The expected duration for achieving this was 120 minutes, but the system failed to reach the target temperature within the set time. As a result, the RAMP stage was automatically extended to 16 minutes and 25 seconds more, with the total freezing time extending to 200 minutes.

🔗 Learn More: Lyophilization Temperature Guidelines

Key recorded values during this cycle:

- Freezing Temperature Range: 5.0°C to -48.0°C

- Total Time Taken: 200 minutes

- Set Chamber Pressure: 0.950 mbar

- Max Chamber Pressure: 905 mbar

- Shelf Temperature: Set at 5.0°C

- Chamber Inlet Temp: 5.0°C

- Chamber Outlet Temp: 5.4°C

- Condenser Pressure: 1125 mbar

- Condenser Temperature: 72.5°C

Key Takeaway

The failure to achieve -48°C within the designated time suggests potential equipment inefficiency or malfunction. Understanding and addressing the reasons behind this delay is crucial to maintaining product quality and process efficiency.

🔗 Related: Impact of Temperature Overshoots During Lyophilization

What is RAMP in freeze-drying?

The RAMP step refers to the gradual temperature reduction phase during the freezing stage. It ensures the product freezes uniformly, preventing structural damage or formulation instability. This phase is carefully monitored to control both temperature descent and pressure stability. Explore More: The Essential Principles of Freezing Techniques, Benefits, and Best Practices

Why the Freeze-Drying Cycle Step (RAMP) Was Extended

The RAMP phase was extended because the system failed to achieve the desired temperature of -48.0°C within 120 minutes. To meet the required freeze condition, the system continued the cooling process until the temperature goal was met—resulting in a total cycle time of 200 minutes. Must Read: Compressor Excess Pressure: Causes and Solutions

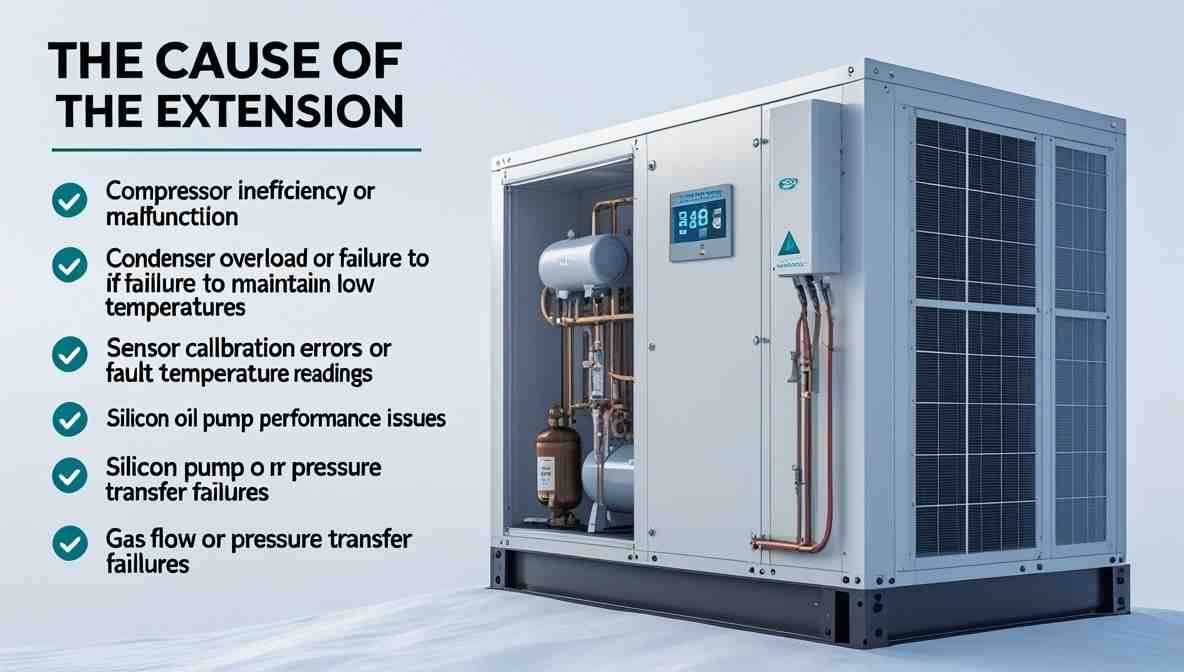

The Cause of the Extension

The possible reasons for the delay in reaching -48°C may include:

- Compressor inefficiency or malfunction

- Condenser overload or failure to maintain low temperatures

- Sensor calibration errors or faulty temperature readings

- Silicon oil pump performance issues

- Gas flow or pressure transfer failures

🔗 Helpful Guide: Failure of a Silicon Oil Pump During Freeze Drying

🔗 Also Read: Refrigerating Compressor Failures in Freeze Drying Processes

Each of these issues can affect the cooling rate and overall cycle performance, necessitating technical inspection and corrective actions.

Impact Assessment of the RAMP step extension in freeze-drying

Extending the RAMP phase affects:

- Product Integrity: Slower freezing may result in larger ice crystals, potentially damaging the product matrix.

- Cycle Efficiency: Prolonged freeze times increase energy usage and operational costs.

- Equipment Wear: Excess load on compressors and condensers may reduce their lifespan.

- Process Validation: Consistency is key in pharmaceutical and food freeze-drying; extended steps may compromise batch uniformity.

🔗 Related Topic: Defects in Lyophilized Product: A Complete Easy Guide

🔗 Deep Dive: Defect Classification in Lyophilized Products: A Quality Guide

Troubleshooting During RAMP Phase (5.0°C to -48.0°C)

Below are common freeze-drying troubleshooting points for the extended RAMP phase:

-

Excess Chamber Pressure: Inspect the compressor load and gas seals.

-

Gas Transfer Failure: Check vacuum line blockages or valve leaks.

-

Compressor Pressure Overshoot: Monitor for possible overcompression and regulate settings.

-

Condenser Inefficiency: Clean or service the condenser coil and circulating coolant.

-

Temperature Sensor Calibration: Ensure RTDs or thermocouples are accurate and functional.

🔗 Troubleshoot Here: Freeze Dryer Troubleshooting Guide

🔗 More Info: Failure Detection and Elimination of Fuse Failure During Lyophilization

Summary: RAMP Step Extension in Freeze-Drying

- Initial Target: Achieve -48°C in 120 minutes

- Actual Outcome: Took 200 minutes to reach -48°C

- Root Cause: Cooling failure, likely from compressor, condenser, or sensor issues

- Impact: May affect product quality, cost, and process time

- Recommended Action: System inspection, maintenance, and sensor recalibration

🔗 Suggested Read: Lyophilizer Operational Qualification

🔗 Learn Best Practices: Lyophilization Validation Best Practices 2025

Conclusion of RAMP step extension in freeze-drying

The extension of the RAMP step in a freeze-drying cycle is a significant deviation that can signal deeper equipment or process issues. Monitoring temperature drops, maintaining system components, and ensuring accurate sensor readings are essential to avoid such delays. Prompt troubleshooting helps maintain the reliability and consistency of freeze-drying operations.

🔗 Explore This: Temperature Control in Freeze Drying Processes

FAQs on RAMP step extension in freeze-drying

What does the RAMP step mean in freeze-drying?

The RAMP step is the controlled cooling stage that gradually reduces shelf temperature during freezing to avoid thermal shock and maintain product quality.

Why is reaching -48°C important?

This low temperature ensures complete freezing of the product, preventing collapse or melting during primary drying.

Why was the RAMP phase extended?

It was extended because the system failed to reach -48°C within the set time of 120 minutes.

What causes failure in reaching the set freeze temperature?

Possible reasons include malfunctioning compressors, condenser inefficiency, sensor errors, or issues with the silicon pump.

What pressure was recorded during freezing?

Chamber pressure peaked at 905 mbar, and condenser pressure was 1125 mbar.

Can extended RAMP time damage the product?

Yes. Longer freeze times can lead to larger ice crystals, affecting product texture and structure.

What should be inspected first during troubleshooting?

Start with the compressor, condenser, temperature sensors, and gas flow lines.

How can this issue be prevented in the future?

Regular preventive maintenance, sensor recalibration, and process monitoring can help avoid RAMP stage extensions.

What causes a freeze dryer to take longer during the RAMP phase?

🔗 See: Failure Compressor Excess Temperature During Freezing

How do you detect freezing failures early?

🔗 Check: Failure of an Active MKS or Pirani Pressure Sensor in Freeze Dryer