Did you know the global pharmaceutical lyophilization Cycle Development market is expected to hit $15.2 billion by 2027? It’s growing at an 8.1% CAGR. This shows how crucial it is to master lyophilization, or freeze-drying, in the pharmaceutical world. This guide will walk you through the key steps and best practices for creating successful lyophilization cycles. It will help you improve your freeze-drying processes and ensure consistent product quality.

Key Takeaways

- Understand the fundamental principles of the freeze-drying process and its impact on product quality attributes.

- Explore the essential equipment requirements and setup considerations for successful lyophilization cycles.

- Discover the key stages and parameters involved in the development of a robust lyophilization cycle.

- Learn strategies for optimizing the primary drying phase to maximize efficiency and product quality.

- Gain insights into secondary drying optimization and effective endpoint determination.

- Understand the scale-up considerations and process transfer requirements for lyophilization cycles.

- Implement risk assessment and mitigation strategies to ensure the success of your lyophilization processes.

Understanding the Fundamentals of Freeze-Drying Process

Lyophilization, or freeze-drying, is a key process in making medicines. It keeps the medicine’s quality and effectiveness. This method uses sublimation, where ice turns directly into vapor, skipping the liquid stage. This helps keep the medicine’s active parts safe and extends its shelf-life.

Basic Principles of Sublimation

Lyophilization works by using low temperature and reduced pressure. This lets the frozen water turn into vapor without becoming liquid. This careful control helps keep the medicine’s active parts safe during drying.

For troubleshooting lyophilization challenges such as equipment malfunctions or identifying performance issues, consider exploring the detailed insights provided in our Lyophilizer Operational Qualification Guide. This can be instrumental in setting up effective lyophilization cycles.

Critical Quality Attributes in Lyophilization

- Residual Moisture Content: Keeping the water content low is key to stopping microbial growth and keeping the product stable.

- Cake Appearance and Integrity: A uniform cake shows the lyophilization was successful, keeping the product quality high.

- Reconstitution Time: How fast and easy it is to mix the medicine is important for patient use.

- Potency and Purity: Keeping the drug’s strength and purity right is crucial for its safety and effectiveness.

Equipment Requirements and Setup

Good lyophilization needs special equipment, like lyophilizer recipe design and lyophilization systems. These machines control temperature, pressure, and more to dry the product right. Every part, from the freeze-dryer to vials and stoppers, is important for success.

| Equipment | Function |

|---|---|

| Freeze-Dryer | Provides the controlled temperature and pressure environment for the sublimation process. |

| Vials and Stoppers | Contain and seal the product during and after lyophilization, maintaining the sterile environment. |

| Loading/Unloading System | Facilitates the efficient transfer of product into and out of the freeze-dryer. |

“Mastering the fundamentals of freeze-drying is the key to unlocking the full potential of your pharmaceutical formulations.”

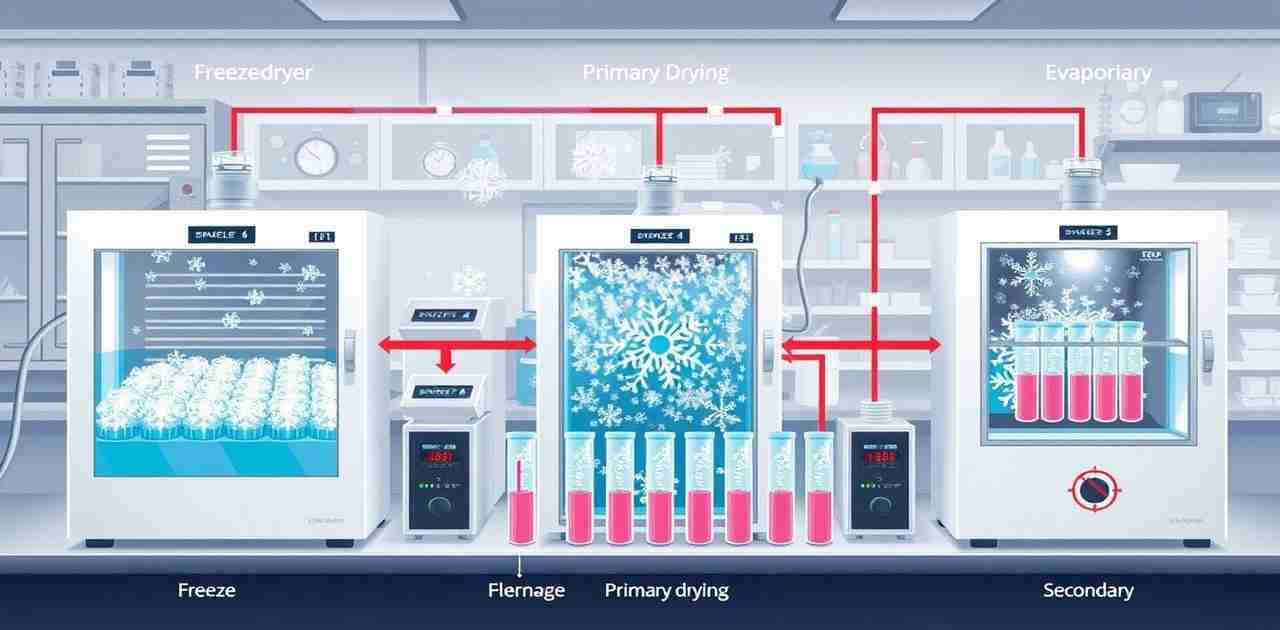

Lyophilization Cycle Development: Key Stages and Parameters

Creating a good lyophilization (freeze-drying) cycle is key for making biologics. This process has several important stages. Each stage has its own needs and settings that affect the product’s quality and how well it lasts.

The main stages of lyophilization cycle development are:

- Freezing: First, the product’s temperature is lowered to freeze it. The freezing rate, how concentrated the product is, and its pH matter a lot. They help shape the ice crystals, which affects drying and product quality.

- Primary Drying: Next, the frozen water is removed through sublimation. This is where ice turns straight into vapor without being liquid. It’s important to control temperature and chamber pressure well to dry the product right without damaging it.

- Secondary Drying: Last, any water left in the product is removed. This step needs higher temperatures and lower chamber pressures. It helps get the product to the right moisture level.

Getting through these stages and setting the right freeze drying cycle parameters is vital for lyophilization for biologics. Thinking about the product, its mix, and the equipment is crucial. This helps make strong and dependable lyophilization processes. These processes are key to making high-quality biopharmaceuticals.

| Lyophilization Stage | Key Parameters | Desired Outcomes |

|---|---|---|

| Freezing |

|

|

| Primary Drying |

|

|

| Secondary Drying |

|

|

Knowing the key stages and parameters of the freeze drying cycle helps manufacturers make better lyophilization processes. These processes are essential for making high-quality biopharmaceuticals. This ensures the success of their lyophilization for biologics work.

Optimizing Primary Drying Phase for Maximum Efficiency

The primary drying phase is key in lyophilization. It greatly affects the success of the process. Important factors include temperature control strategies and chamber pressure management.

Temperature Control Strategies

Keeping the temperature just right is crucial. It helps keep the product safe and the process on track. Here are some ways to control temperature:

- Watch the eutectic temperature closely to avoid damage

- Use special temperature ramps to slowly heat the product

- Adjust the shelf temperature with feedback systems

Chamber Pressure Management

The right chamber pressure is vital for drying. Here’s how to manage it:

- Keep an eye on and adjust the vacuum level

- Use pressure control tools like valves and sensors

- Think about adding inert gases like nitrogen

Product Resistance Monitoring

It’s important to watch how the product dries. Use methods like temperature checks and vapor flow measurements. This helps the process run smoothly.

| Technique | Benefits |

|---|---|

| Product Temperature Monitoring | Provides real-time data on product temperature and helps identify the end of primary drying |

| Vapor Flow Measurement | Allows for monitoring of the drying rate and detection of changes in product resistance |

| Impedance Analysis | Enables the assessment of product resistance and optimization of the drying cycle |

Using these advanced methods can make lyophilization more efficient. This leads to better product quality and process performance for pharmaceutical and biotech companies.

Secondary Drying Optimization and Endpoint Determination

Optimizing the secondary drying phase is key in lyophilization. This stage focuses on removing the last bits of moisture from the product. It’s important for keeping the product stable and of high quality. Finding the right balance in secondary drying and knowing when to stop is vital for freeze-drying success.

The annealing step in freeze-drying can greatly improve product quality. It involves warming the product slightly during secondary drying. This makes the product more stable and less prone to moisture absorption. It helps in reducing the formation of amorphous areas, which can increase moisture and shorten shelf life.

It’s important to keep an eye on how the secondary drying is going. Tools like gravimetric analysis and thermal analysis can help. They give insights into how the drying is progressing. This way, manufacturers can know exactly when to stop the drying cycle. By fine-tuning secondary drying and monitoring the drying process, products can be made consistently and reliably.

| Optimization Strategy | Benefit |

|---|---|

| Annealing during secondary drying | Improved product crystallinity and stability |

| Residual moisture content monitoring | Accurate determination of drying endpoint |

| Thermal analysis techniques | Insights into drying kinetics and process optimization |

By managing secondary drying well and using the right methods to determine when to stop, manufacturers can make high-quality freeze-dried products. This leads to successful lyophilization results.

“Optimizing the secondary drying phase is crucial for achieving the desired product quality and stability in lyophilization.”

Scale-Up Considerations and Process Transfer

Moving a lyophilization process from the lab to large-scale production is tough. It’s important to think about how different equipment affects the process. This ensures the quality of the product stays the same during freeze-drying.

Equipment Differences and Adjustments

Scaling up means dealing with different equipment designs. This includes shelf size, chamber volume, and how much you can load. You might need to tweak things like shelf temperature and chamber pressure to get the same results. It’s key to check and fine-tune these details for a smooth transition.

Critical Process Parameters During Scale-Up

- Product temperature

- Chamber pressure

- Sublimation rate

- Residual moisture content

Keeping an eye on these important factors is vital during scale-up. If they change, you might need to tweak the lyophilization cycle. This helps keep the product quality and consistency.

Risk Assessment and Mitigation

Scaling up brings new risks, like more batch-to-batch variation and product damage. It’s crucial to assess these risks and find ways to reduce them. This includes doing lyophilization scale-up studies, checking critical process parameters, and setting up strong quality control.

| Lyophilization Scale-Up Considerations | Freeze Drying Process Optimization |

|---|---|

|

|

“Successful scale-up of a lyophilization process requires a comprehensive understanding of the critical process parameters and their interdependencies. Careful planning and risk mitigation are key to ensuring consistent product quality across different manufacturing scales.”

Conclusion of lyophilization Cycle Development

Creating a good lyophilization cycle is key in the pharmaceutical world. It makes sure drugs stay stable and work well. By knowing how freeze-drying works, managing important steps, and improving drying phases, companies can make a strong cycle.

We’ve looked at what makes a lyophilization cycle good, from the right equipment to scaling up. A careful and ongoing approach helps improve product quality and makes making drugs more efficient. This leads to safer and more effective medicines for patients.

The field of lyophilization is always changing. Keeping up with new tech and methods is vital. By using the tips from this guide, experts can handle the challenges of making a lyophilization cycle. This helps in launching products successfully and improving health outcomes for patients.

FAQs of lyophilization Cycle Development

Stages and Cycle of Lyophilization

Lyophilization, or freeze-drying, involves three main stages: freezing, where the product is cooled to convert water into ice; primary drying, where ice is removed through sublimation under vacuum; and secondary drying, where residual moisture is eliminated through desorption. A typical cycle includes all these stages and is carefully monitored to ensure product integrity.

Process Duration

The lyophilization process generally takes 24 to 48 hours, depending on the product and equipment.

TC and Tg in Lyophilization

TC (Thermocouple) refers to sensors used to monitor temperature during the process. Tg (Glass Transition Temperature) represents the temperature at which the product transitions from a glassy to a rubbery state, critical for ensuring product stability.

For more insights into ensuring optimal lyophilization performance, explore our guide on CGMP guidelines for lyophilized product manufacturing.