A single failure valve in a freeze dryer can cause big delays and cost thousands. Freeze dryer valves are key for making pharmaceutical products right. This guide will cover why valves fail, how to fix them, and how to keep your freezer dryer working well.

Key Takeaways

- Understand the vital role of valves in the lyophilization process and the potential consequences of valve failure

- Identify the common causes and symptoms of a faulty freeze dryer valve

- Learn effective diagnostic techniques to pinpoint the root cause of the valve issue

- Discover step-by-step procedures for replacing a failed valve and implementing preventive maintenance strategies

- Troubleshoot common valve-related problems to keep your freezer dryer running smoothly

Understanding the Importance of Freeze Dryer Valves

Freeze dryer valves are key to the lyophilization process. They control gas flow and keep vacuum levels right. This is vital for preserving pharmaceutical, biotechnological, and food products.

Role of Valves in the Lyophilization Process

Freeze dryer valves manage the flow of gases like nitrogen or argon in the drying chamber. This is crucial for the right vacuum. They also remove water vapor for efficient drying.

Potential Consequences of Valve Failure

- Compromised product quality: A broken freeze dryer valve can cause uneven drying. This harms the product’s quality, potency, and stability.

- Prolonged drying cycles: Valve failure messes with the lyophilization process. This means longer drying times and less production efficiency.

- Non-compliance with CGMP (current good manufacturing practice) standards: The FDA demands strict process control, including working valves. Valve failures can lead to non-compliance and legal issues.

Knowing how crucial freeze dryer valves are in lyophilization is key to making quality products. By understanding their importance and failure risks, manufacturers can keep their equipment in top shape. This helps avoid problems in their work.

Failure Valve in Freeze Dryer: Causes and Symptoms

Freeze dryers rely on valves to work well. If these valves fail, it can cause big problems. Knowing why and how to spot valve failures helps keep your freezer running smoothly.

A common reason for freeze dryer valve failure is a bad valve coil. This part helps the valve open and close. Problems with the wiring or control system can also cause valves to malfunction, leading to vacuum valve malfunctions.

Another issue is low compressed air pressure. Freeze dryers use air pressure to work their valves right. Not enough air pressure can stop the valves from working, which messes up the freeze-drying process.

- closed switch remains activated even when the valve is opened

- Valve fails to open despite receiving the activation signal

- Erratic valve behavior or unexpected valve closures

Spotting these symptomatic signs of valve failure early can help fix the problem before it gets worse. This keeps your freeze-drying operations running smoothly.

“Addressing valve failures in freeze dryers is crucial for maintaining consistent product quality and maximizing process efficiency.”

Diagnosing the Failure Valve Issue

First, you need to figure out what’s wrong with the freeze dryer vacuum valve. Look at the valve parts and do tests on the electrical and pneumatic parts. This helps you find the main problem and fix it.

Visual Inspection Techniques

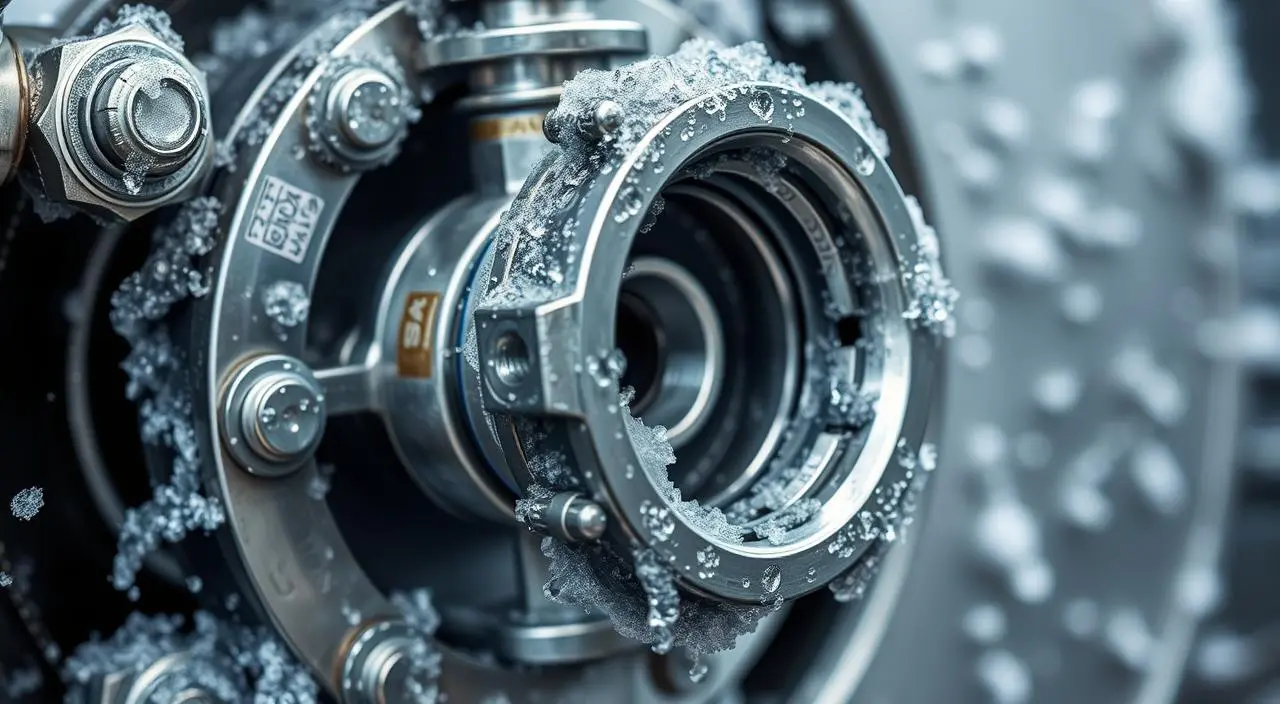

Start by looking at the freeze dryer valve closely. Check the valve body, seals, and moving parts for any damage or blockages. Watch for cracks, corrosion, or dirt that might stop the valve from working right.

Electrical and Pneumatic Testing

After checking visually, test the electrical and pneumatic parts too. Make sure the valve’s electrical parts, like the solenoid, work well. Also, check if the valve gets the right air pressure and if the pneumatic system works as it should.

| Test | Purpose | Procedure |

|---|---|---|

| Electrical Testing | Verify the electrical components of the valve |

|

| Pneumatic Testing | Ensure the valve is receiving the correct air pressure |

|

By looking at the valve’s visual, electrical, and pneumatic parts, you can find out what’s causing the problem. Then, you can fix it.

Resolving the Failure Valve Problem

When a freeze dryer valve fails, act fast and right. Replacing the valve and keeping up with maintenance is key. This keeps your freeze drying process smooth and CGMP compliant.

Failure Valve Replacement Procedures

To fix a bad valve in your freeze dryer, here’s what to do:

- Turn off the freeze dryer and close valves on both sides of the faulty valve.

- Disconnect the electrical and pneumatic lines from the valve carefully.

- Take out the old valve and clean the area where it was mounted.

- Put in the new valve, reconnect the lines, and make sure it fits right.

- Do a leak test and check if the valve works as it should.

- Write down the steps you took and update your maintenance logs.

Preventive Maintenance Strategies

To avoid valve failures and keep up with CGMP rules, try these tips:

- Regularly inspect valves. Look at them and test their function often to catch problems early.

- Implement a comprehensive maintenance program: Have a plan for keeping valves well-lubricated, clean, and replaced when needed.

- Train your staff: Make sure your team knows how to take care of and replace freeze dryer valves.

- Keep detailed records: Keep track of all work done on valves to show you follow CGMP rules.

By doing these things for valve care and replacement, you can cut down on failures. This keeps your freeze drying process reliable and CGMP compliant for a long time.

Troubleshooting Common Valve-Related Issues

In the world of freeze dryers, valve issues are common but solvable. This section offers practical solutions for leaks, sticking valves, and pressure changes. These tips will help keep your freezer dryer working well.

Valve leaks are a big problem, affecting the drying process. Check for cracks or damage during a visual inspection to find the leak. Replacing the faulty valve is the next step. Regular maintenance and lubrication can also prevent leaks and extend your freezer’s life.

Sticking valves can be a big headache, often due to residue or misalignment. Use electrical and pneumatic tests to find the cause. Then, take steps to fix the valve. Cleaning and adjusting your freezer dryer regularly can prevent sticking valves and keep it running smoothly.

FAQ

What are the common causes of failure valves in freeze dryers?

Common causes include a faulty valve coil, a loose valve connection, and issues with the limit switch. Low compressed air pressure can also cause problems with electropneumatic valves.

How can I diagnose a failure valve issue in my freeze dryer?

Start by visually checking the valve parts. Then, do electrical and pneumatic tests to find the issue. This could be a broken valve coil or wiring issues.

What are the steps to replace a faulty valve in a freeze dryer?

First, shut down the freezer. Then, isolate and disconnect the valve’s electrical and pneumatic connections. Finally, install the new valve as the manufacturer directs.

How can I implement preventive maintenance strategies to avoid future valve failures?

Regularly check and test the valves. Clean the parts and keep compressed air pressure right. This helps prevent valve failures and keeps your freeze dryer in CGMP compliance.

How can I troubleshoot common valve-related issues in my freeze dryer?

Start with a visual check for leaks or sticking valves. Then, test pressure and flow. Make sure the valve’s electrical and pneumatic systems work right.