Understanding Compressor Excess Temperature Failure in Freeze Drying

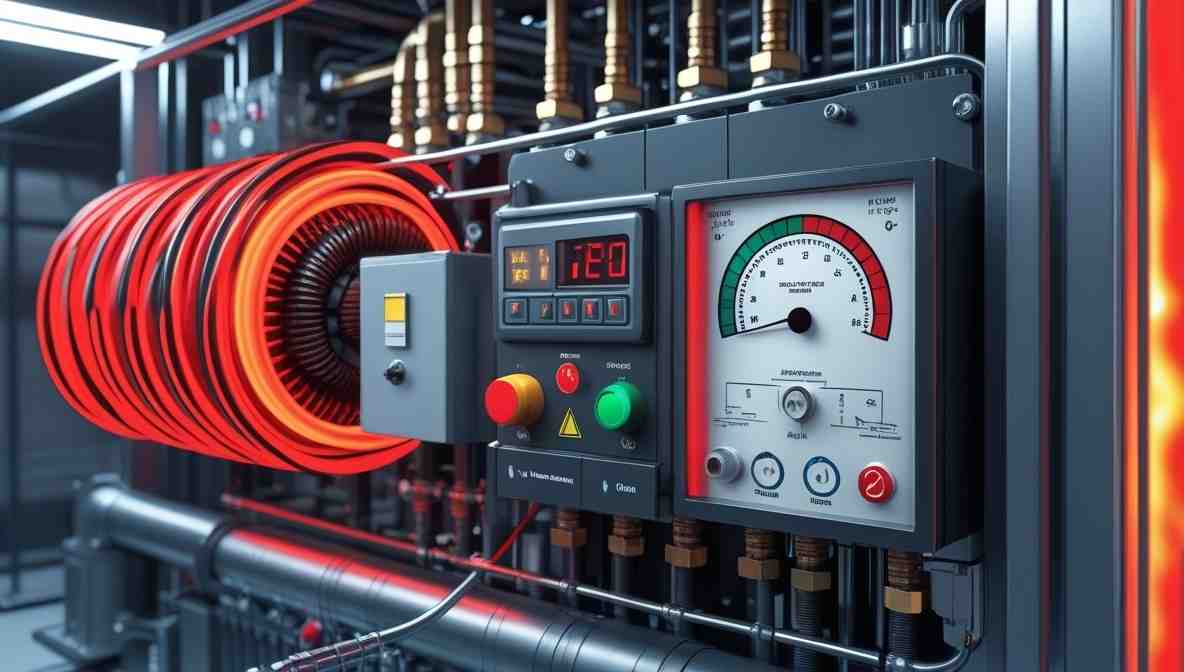

In freeze-drying processes, compressor failures due to excess temperature can significantly impact system performance and product quality. This failure occurs when one of the motor protection systems detects excessive coil temperature and shuts down the corresponding compressor. The issue persists until the motor coil cools down and an additional waiting period elapses before restarting.

Causes of Compressor Excess Temperature Failure

Several factors contribute to this failure, including:

- Short-circuit in the coil: Electrical faults within the compressor’s coil can lead to overheating and automatic shutdown.

- Frequent switching cycles: Rapidly turning the compressor on and off can cause thermal overload.

- Lack of refrigerant: Insufficient refrigerant levels affect heat dissipation, causing excessive temperature rise.

- Blocked injection valves: Improper refrigerant flow due to clogged valves results in inadequate cooling.

Impact on the Freeze-Drying Process

Compressor excess temperature failures can disrupt the freeze-drying cycle, leading to process inefficiencies and product degradation. The freeze-drying process consists of distinct phases, with temperature fluctuations affecting product stability.

Freezing Process Steps:

| Phase | Time | Temperature (°C) |

|---|---|---|

| Freezing | 1 min | 10 |

| Freezing | 20 min | 10 |

| Freezing | 600 min | 40 |

| Freezing | 140 min | 40 |

When compressor failures occur, the inability to maintain precise temperature control can result in incomplete sublimation, product inconsistency, and prolonged cycle times.

Preventive Measures and Solutions

To mitigate compressor overheating and its impact on the freeze-drying process, consider the following strategies:

- Monitor motor temperature regularly. Use thermal sensors to detect early signs of overheating.

- Optimize compressor cycles. Avoid frequent switching to prevent excessive thermal stress.

- Ensure proper refrigerant levels. Regularly check and refill refrigerant to maintain cooling efficiency.

- Perform routine maintenance—inspect and clean injection valves to ensure unobstructed refrigerant flow.

Related Insights and Internal Resources

For an in-depth understanding of freeze-drying equipment performance, regulatory compliance, and troubleshooting, explore the following resources:

- Verification of Base Values

- Freeze Drying Unit Leak Test

- Test of Freeze Dryer CIP Process Efficiency

- Impact of Temperature Overshoots During Lyophilization

- Refrigerating Compressor Failures in Freeze Drying

- Lyophilizer Cleaning Validation

- Freeze Dryer Troubleshooting Guide

By implementing effective monitoring and maintenance strategies, manufacturers can prevent compressor excess temperature failures and optimize the freeze-drying process for consistent, high-quality results.

Conclusion

Compressor excess temperature failures can cause serious disruptions in the freeze-drying process, impacting both efficiency and product quality. By understanding the root causes and implementing effective preventive measures, manufacturers can enhance system reliability and maintain optimal drying conditions. Regular monitoring, maintenance, and process optimization are key to minimizing the risk of failures and ensuring consistent performance.

FAQs

1. What are the main causes of compressor excess temperature failure?

Short-circuits in the coil, frequent switching cycles, a lack of refrigerant, and blocked injection valves are common causes of this failure.

2. How does compressor overheating affect the freeze-drying process?

It leads to temperature fluctuations, incomplete sublimation, prolonged drying cycles, and potential product degradation.

3. What can be done to prevent compressor excess temperature failures?

Regular monitoring, optimizing compressor cycles, maintaining proper refrigerant levels, and performing routine maintenance are effective preventive measures.

4. How long does it take for the compressor to restart after overheating?

The compressor restarts only after the motor coil has cooled down and an additional waiting period has elapsed.

5. Why is refrigerant level important in preventing compressor failures?

Adequate refrigerant levels ensure proper heat dissipation, preventing excessive temperature rise and system shutdowns.