Construction of Freeze Dryer plays a vital role in understanding how this advanced preservation equipment functions in the pharmaceutical, biotechnology, and food industries. A freeze dryer, also known as a lyophilizer, works by removing water from frozen products under vacuum, allowing ice to sublimate directly into vapor.

This process helps preserve sensitive materials without damaging their structure, making it vital for drug manufacturing, food preservation, and biological storage.

In this article, we’ll explore the construction of freeze dryers, their types, working principles, and key applications.

Table of Contents

ToggleConstruction of Freeze Dryer

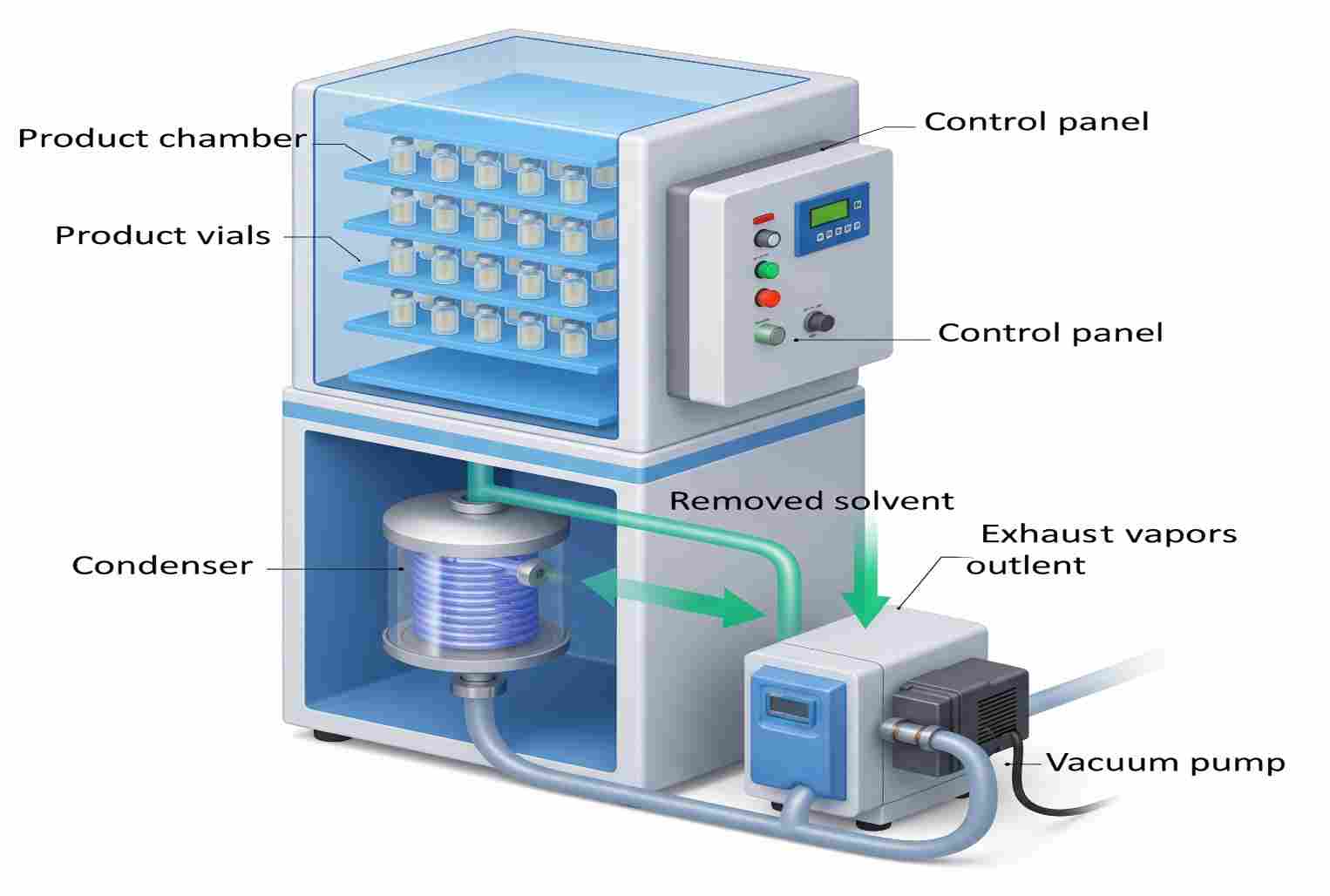

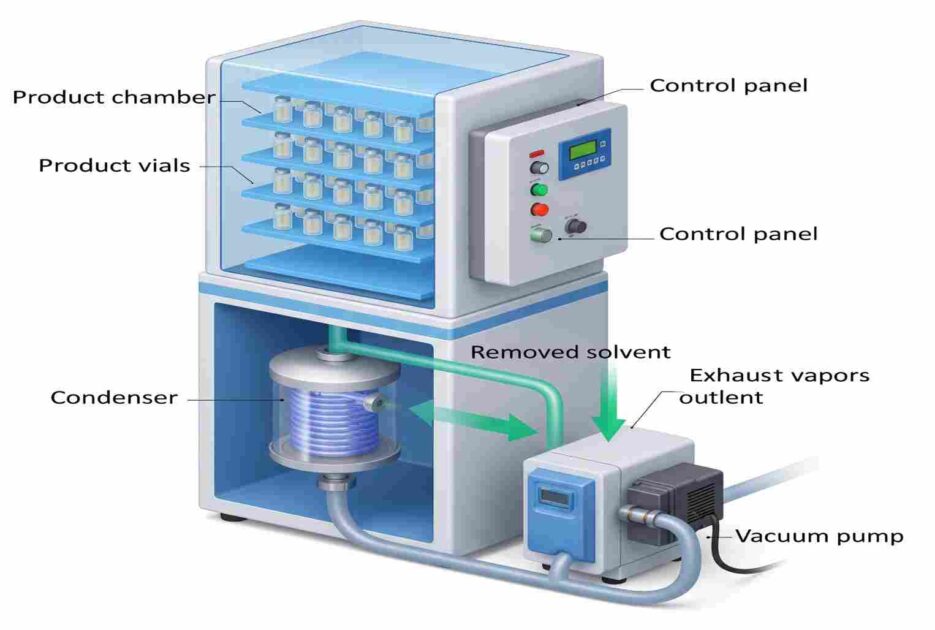

A freeze dryer is built with critical components such as:

- Vacuum chamber: where products are placed for drying.

- Shelves or trays: that hold vials, extracts, or solutions.

- Condenser: captures and traps water vapor as ice at very low temperatures.

- Vacuum pump: reduces pressure to enable sublimation.

- Control system: regulates pressure, temperature, and drying cycles.

Together, these components ensure efficient moisture removal while protecting product quality. For further understanding, you can check our detailed guide on freeze dryer equipment components and functions.

Product Chamber

- This is the main chamber where the product to be dried is placed.

- It contains shelves that hold the product vials.

- The chamber is maintained at low temperature and vacuum to allow ice to turn directly into vapor (sublimation).

Product Vials

- Small glass containers that hold the sample (liquid or semi-solid).

- During freeze-drying, the water content inside the vials is removed without affecting the chemical structure of the product.

Control Panel

- The electronic unit is used to operate and monitor the freeze dryer.

- It controls temperature, vacuum pressure, and drying cycles.

- Operators can adjust parameters for primary and secondary drying stages.

Condenser

- The condenser is a cold trap where vaporized solvent (mostly water) is captured.

- It prevents vapors from reaching and damaging the vacuum pump.

- Ice collects here as the removed moisture solidifies.

Vacuum Pump

- Creates the necessary low-pressure environment inside the product chamber.

- Reduces the boiling point of water, enabling sublimation at low temperatures.

- Excess air and exhaust vapors are expelled through the pump outlet.

Removed Solvent

- This refers to the water (or other solvents) removed from the product.

- It gets trapped in the condenser as ice and then later drained or melted away.

Exhaust Vapors Outlet

- Outlet for non-condensable gases and excess vapors from the vacuum pump.

- Maintains smooth operation of the system.

Types of Freeze Dryers

There are three main types of freeze dryers, each designed for specific applications:

Tray Freeze Dryer

- Consists of a rectangular chamber with shelves and trays.

- Commonly used for pharmaceutical solutions, tissue extracts, and injectables.

- Provides uniform drying, making it ideal for large-scale production.

👉 Learn more about GMP freeze drying guidelines.

Rotary Freeze Dryer

- Has a cylindrical rotating reservoir.

- Best for drying pellets, powders, cubes, and liquids.

- Rotation ensures even drying of bulk materials.

Manifold Freeze Dryer

- Uses insulated tubes connected by circular bends to attach multiple containers.

- Suited for small-scale labs handling multiple small samples.

👉 For cost evaluation, read about freeze dryer installation cost and ROI.

Working Principle of Freeze Drying

Freeze-drying, also called lyophilization, occurs in three main stages:

Freezing

- The sample is cooled to –40°C to –60°C, turning water into ice.

- The remaining liquid forms a glassy state due to high viscosity.

Primary Drying

- Ice is sublimated under deep vacuum (10⁻⁴ to 10⁻⁵ atm) at –45°C to –20°C.

- Produces a porous product structure.

👉 Optimization strategies for this stage are discussed in primary drying phase optimization.

Secondary Drying

- Residual water is removed by gradually heating the product to 10–15°C under vacuum.

- The final product has less than 5% moisture, ensuring long-term stability.

👉 See more about primary and secondary drying in lyophilization.

Applications of Freeze Dryers

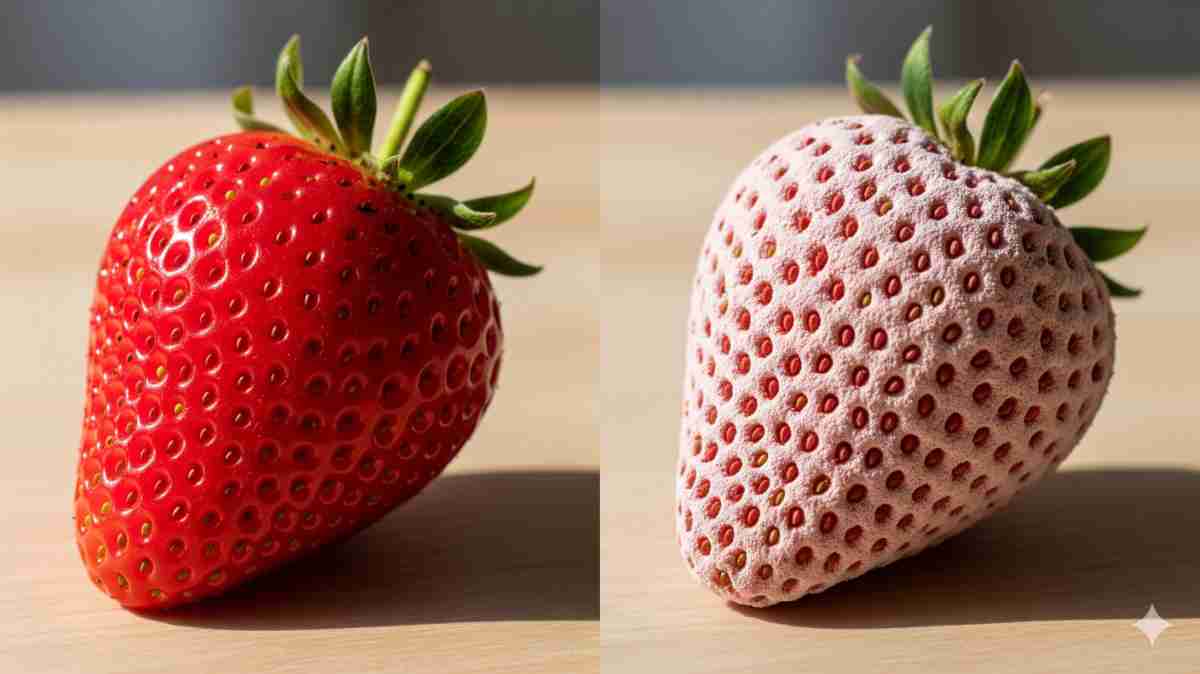

Freeze dryers are widely used for:

- Pharmaceuticals: vaccines, injectables, and protein-based drugs. (Applications in biopharmaceuticals)

- Food industry – preservation of fruits, vegetables, dairy, and ready-to-eat meals. (Best fruits for freeze drying)

- Biologicals: blood products, enzymes, and microbial cultures.

- Chemicals: improving solubility, storage stability, and solvent removal.

Advantages of Freeze-Drying

- Retains nutrients, structure, and activity of sensitive products.

- Provides a long shelf life with minimal contamination risk.

- Rapid reconstitution of dried material.

- Effective for thermosensitive and oxidation-prone substances.

👉 For efficiency tips, see energy efficiency in lyophilization.

Limitations of Freeze Drying

- High cost compared to conventional drying methods.

- Requires aseptic handling during loading and unloading.

- Some products may be unstable under very low temperatures.

👉 Learn how to avoid issues in our freeze dryer troubleshooting guide.

Conclusion of Construction of Freeze Dryer

The construction of freeze dryers revolves around vacuum chambers, condensers, pumps, and advanced controls that ensure precise drying. With tray, rotary, and manifold designs, freeze dryers serve industries from pharmaceuticals to food preservation. While the process is cost-intensive, it delivers unmatched product stability, making it a cornerstone of modern preservation techniques.

For an in-depth understanding of freeze-drying technology, explore our complete guide on the lyophilization process.

✅ In summary of the construction of Freeze Dryer

The freeze dryer works by first freezing the product in vials inside the product chamber. The vacuum pump creates a low-pressure environment, causing ice to sublime into vapor. These vapors are trapped in the condenser as ice, leaving the dried product behind. The control panel ensures all parameters (temperature, vacuum, and time) are properly managed.

✅ FAQs on Construction of Freeze Dryer

Q1. What is a freeze dryer?

A freeze dryer, or lyophilizer, is equipment that removes water from frozen products under vacuum through sublimation.

Q2. What are the main parts of a freeze dryer?

The key components are the product chamber, shelves, condenser, vacuum pump, and control system.

Q3. How does a freeze dryer work?

It works in three steps: freezing the product, sublimating ice under vacuum, and removing residual moisture by secondary drying.

Q4. What are the types of freeze dryers?

The three main types are tray freeze dryers, rotary freeze dryers, and manifold freeze dryers.

Q5. Why is a vacuum pump important in freeze dryers?

The vacuum pump lowers pressure, allowing ice to sublimate directly into vapor without passing through a liquid phase.

Q6. What is the role of the condenser in freeze dryers?

The condenser traps vaporized water as ice, preventing it from reaching and damaging the vacuum pump.

Q7. Where are freeze dryers used?

They are widely used in pharmaceuticals, biotechnology, food preservation, and biological sample storage.

Q8. What is the main advantage of freeze-drying?

Freeze drying preserves product structure, nutrients, and biological activity while extending shelf life.

Q9. What is a limitation of freeze dryers?

Freeze drying is cost-intensive and requires aseptic handling to prevent contamination.

Q10. Why is freeze drying better than conventional drying?

Unlike heat drying, freeze drying prevents thermal damage and maintains product stability and reconstitution ability.