In freeze-drying processes, ensuring optimal performance and compliance with regulatory standards is critical. One key factor influencing both is the Freeze dryer for surface roughness of construction units that come into contact with clean media.

This parameter directly affects the cleanliness, efficiency, and reliability of the freeze dryer. Accurate measurement and verification of surface roughness are essential to maintaining the quality of freeze-dried products and preventing contamination.

This article provides a comprehensive guide on performing surface roughness checks for freeze dryers, outlining the necessary tools, procedures, and acceptance criteria to ensure compliance with industry standards.

Purpose: The objective of this procedure is to ensure that the surface roughness of all construction units in contact with clean media complies with the specified standards. Proper surface roughness is essential to maintaining optimal performance and preventing contamination in freeze-drying processes.

Test Documents Required

- Document Name: [Specify Document Name]

- Document Number: [Specify Number]

- Version Number: [Specify Version]

- Number of Pages: [Specify Pages]

Note: Attach all test documents to the qualification binder as outlined in the attachments section. Mark the first page of each test document with a “Qualification Document” stamp. For additional insights on installation checks, refer to our guide on freeze-drying unit installation checks.

Required Instrumentation and Auxiliary Means

- Equipment Type: Roughness Measuring Instrument

- Reference Type/Model: [Specify Model/Version]

- Serial Number: [Specify Serial Number]

- Calibration Valid Until: [Specify Date]

Acceptance Criteria: The surface roughness values must align with the specified standards. A maximum deviation of 10% from the reference value is permissible. and Implementation Preconditions: Ensure all surfaces are free of dust and dirt. Clean the surfaces if necessary before testing.

Reference Measurements and acceptance criteria

Before and after testing one measurement is to be carried out against the calibrated reference. The result is to be noted in the chart.

If, after testing the freeze drying unit, the result of the reference measurement is not within the limits of the tolerance, then the measurement results have to be confirmed by the realization of random tests with another measuring instrument. If this fails, the complete measurements are to be repeated.

- Conduct a reference measurement before and after testing using a calibrated instrument.

- Record the results in the provided chart. If the deviation exceeds the acceptable limit, replace the measuring instrument.

- If post-test reference measurements fall outside the acceptable range, conduct random tests with another instrument. If discrepancies persist, repeat the entire measurement process. For more guidance, explore our article on lyophilizer operational qualification.

Acceptance Criteria: Reference measurement before testing and after testing is within + 10% of reference value. Test result (pass / fail) Implemented (date / signature)

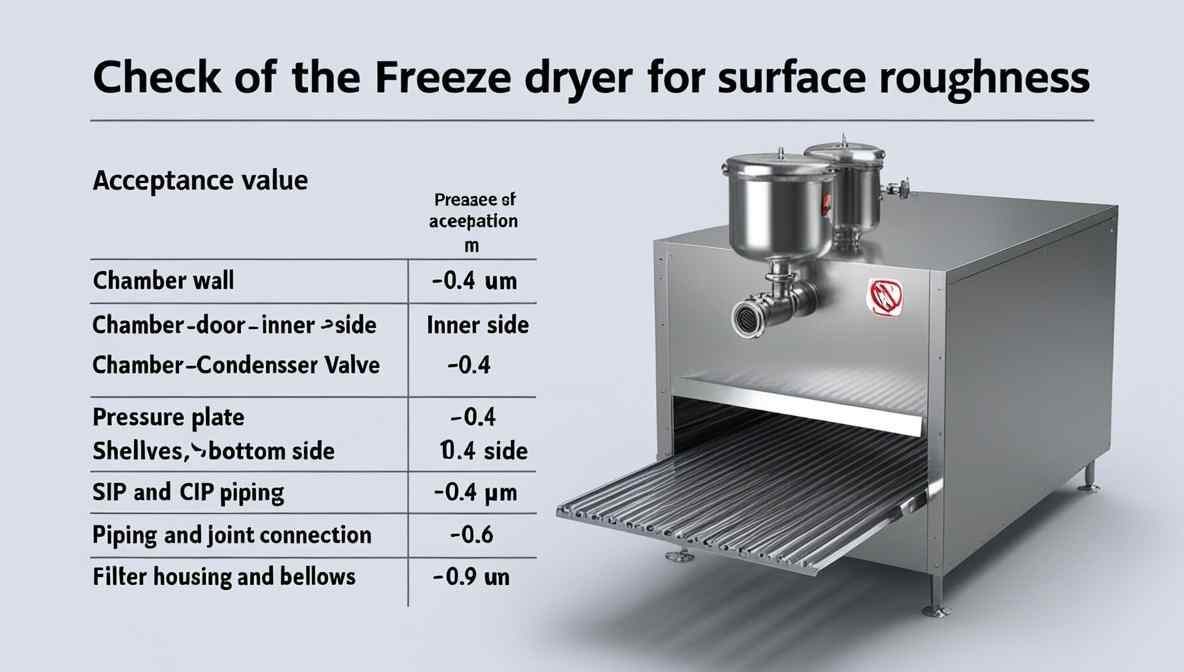

| Description | Acceptance value µM |

| Chamber wall | ≤0.4 µM |

| Chamber door inner side | ≤0.4 µM |

| Chamber-condenser valve | ≤0.4 µM |

| Pressure plate | ≤0.4 µM |

| Radiation shelf | ≤0.4 µM |

| Shelves top side | ≤0.4 µM |

| Shelves, bottom side | 1.4 to 2.0 µM |

| SIP and CIP piping | ≤0.6 µM |

| Piping and joint connection | ≤0.6 µM |

| Filter housing and Bellows | ≤0.6 µM |

Acceptance criteria: The surface roughness is in accordance with the acceptance criteria described in the table above. Test Result pass / fail on compliance.

For a complete guide on cleaning and validation procedures, visit lyophilizer cleaning validation.

Conclusion

Ensuring the surface roughness of freeze dryer components is critical to maintaining high standards in lyophilization. This detailed guide provides step-by-step instructions and acceptance criteria to help achieve compliance. For any freeze-drying processes, adherence to these guidelines ensures both operational efficiency and product safety.

FAQs

- Why is surface roughness important in freeze dryers?

Surface roughness impacts cleanliness and performance, ensuring product safety and compliance. - What is the acceptable surface roughness for a freeze dryer chamber wall?

The chamber wall should have a surface roughness of ≤0.4 µM. - What equipment is used for surface roughness measurement?

A calibrated roughness measuring instrument is used. - What should be done if the reference measurement is outside the acceptable range?

Replace the instrument and conduct the measurement again. - Where can I find more resources on freezing processes?

Visit our freeze dryer troubleshooting guide.

Related Resources

- Learn about the freeze-drying process and stoppering system.

- Explore the sublimation process in lyophilization.

- Check our freeze dryer troubleshooting guide.

- Discover the lyophilization validation best practices for 2025.