Demystifying Primary and Secondary Drying in Lyophilization: A Comprehensive Guide

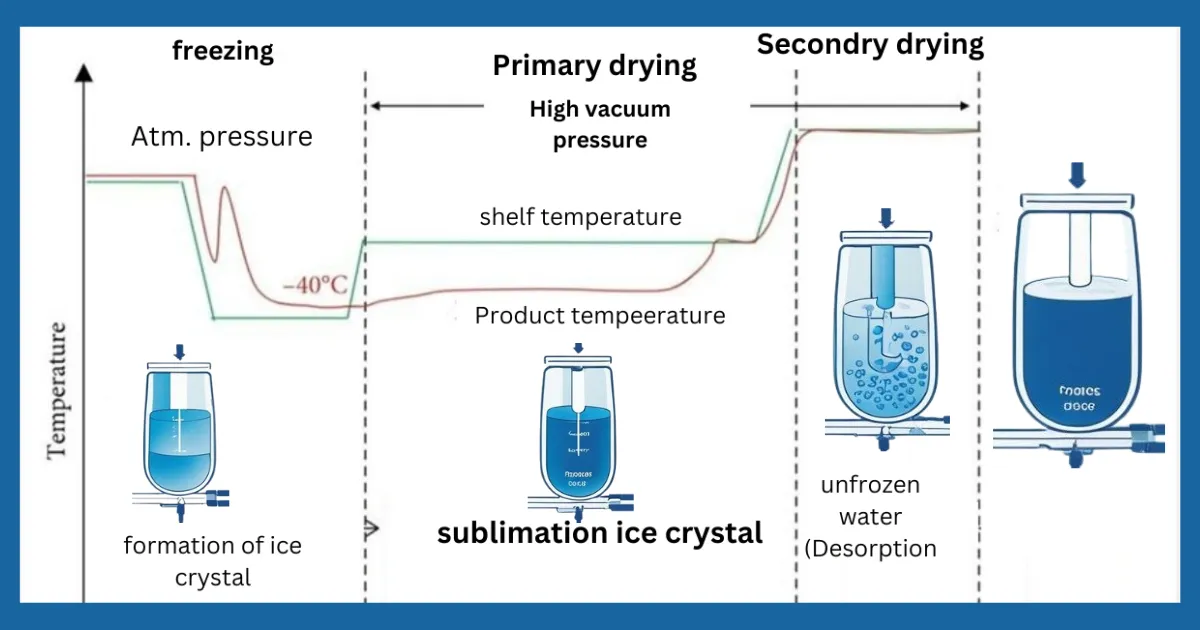

Lyophilization, commonly known as freeze-drying, is a vital process used in various industries, including pharmaceuticals, food preservation, and biotechnology. Central to this process are the stages of primary and secondary drying, each playing a critical role in achieving optimal results.

Lyophilization, commonly known as freeze-drying, is a critical process in the pharmaceutical and biotechnology industries for preserving delicate substances like proteins, vaccines, and antibiotics. Understanding the intricacies of primary and secondary drying is paramount for optimizing lyophilization processes and ensuring product stability and efficacy.

Primary Drying

The Initial Phase or Sublimation

Primary drying is the initial phase of lyophilization, where the majority of the water content is removed from the product under vacuum and at low temperatures. This process occurs by sublimation, wherein ice directly transitions into vapor without passing through the liquid phase. Key points to understand about primary drying include:

- Sublimation: During primary drying, ice crystals in the frozen product sublime, converting directly from solid to vapor.

- Temperature Control: Maintaining controlled temperatures is crucial during primary drying to prevent product collapse or degradation. Typically, temperatures are kept below the product’s collapse temperature but above its glass transition temperature.

- Pressure Adjustment: Vacuum levels are adjusted to facilitate sublimation while preventing excessive drying rates that could lead to collapse or overheating.

- Monitoring of the primary drying stage is essential for controlling temperature and avoiding product damage.

- The detection of the endpoint of primary drying is crucial to initiating secondary drying.

- Recent innovations include patented devices for monitoring primary drying in vials.

- Control of the primary drying stage is challenging due to the difficulty in measuring key parameters like product temperature and interface position.

- Current freeze-dryer control systems often rely on monitored data and empirical knowledge from previous experimental runs.

Example: For instance, in the production of freeze-dried vaccines, primary drying ensures the removal of ice crystals without damaging the vaccine’s antigenic properties, preserving its efficacy during storage and transportation.

Temperature and Pressure during primary drying

- Critical Temperature: Each frozen product has a unique critical temperature, and it is necessary to keep the product temperature safely below this during primary drying to avoid collapse.

- Vapor Pressure Dependence: Product temperature is dependent on the vapor pressure at the ice interface, which is influenced by heat transfer rate (controlled by shelf temperature) and system vacuum level.

- Target Product Temperature: Identify a target product temperature, typically several degrees colder than the critical temperature. Control the shelf temperature and system vacuum level to maintain this target temperature.

- Setting System Pressure: Use the vapor pressure over the ice table to set the system pressure. Monitor the product temperature using thermocouples and adjust the shelf temperature until the target temperature is reached.

- Maintaining Target Temperature: Once the target product temperature is obtained, keep the shelf temperature constant. For products with high resistance to vapor flow, reduce the shelf temperature towards the end of primary drying to maintain the target temperature.

- Avoid Arbitrary Temperature Increases: Do not increase shelf temperature arbitrarily during primary drying.

- Scientific Approach: Use the vapor pressure of ice table to determine an appropriate pressure for freeze-drying, typically 20% to 30% of the vapor pressure of ice at the target product temperature.

- Vacuum Levels: Sublimation can occur when the vacuum level set point is deeper than the vapor pressure of ice at the current product temperature.

- Primary Drying Duration: Continue primary drying until all ice crystals are sublimed.

- Temperature and Pressure Relationship: Lower ice temperatures result in lower saturated vapor pressure.

- Commercial Freeze Dryers: Most cannot control vacuum below 30mTorr consistently, leading to extremely slow freeze-drying at very cold temperatures (less than -40 °C), extending process times to 5–6 days or longer.

How to Determine the End of Primary Drying

- Monitoring Product Temperature: Use a thermocouple probe to monitor product temperature. During active primary drying, the product temperature is colder than the shelf temperature due to the heat used for sublimation. When primary drying is complete, the product temperature will equal the shelf temperature.

- Additional Drying Time: Allow extra drying time (30 minutes to 2 hours) after the product temperature increases to ensure complete sublimation of ice in the entire batch.

- Thermocouple Placement: Place the thermocouple at the bottom and center of the container. If drying in vials, insert the thermocouple in a vial in the middle of the shelf.

- Advanced Process Control Systems: Larger freeze dryers with advanced controls use parallel pressure readings between a Pirani gauge and a capacitance manometer. The Pirani gauge gives a falsely high reading in the presence of water vapor, while the capacitance manometer gives a true pressure reading. When the Pirani reading decreases and matches the capacitance manometer, primary drying is complete.

- External Condensers: Freeze dryers with external condensers can use an isolation valve to close the vapor port temporarily and measure the rise in pressure in the product chamber. When this pressure rise approaches zero, no more water vapor is being generated, indicating the end of primary drying.

Secondary Drying

Removing Residual Moisture (Adsorption Phase)

Secondary drying follows primary drying and involves the removal of residual moisture from the product. While primary drying removes the bulk of water, secondary drying targets the bound water molecules, ensuring the product’s long-term stability. Key aspects of secondary drying include:

- Desorption: Unlike primary drying, which involves sublimation, secondary drying relies on desorption, where bound water molecules are removed from the product.

- Elevated Temperatures: Secondary drying often employs slightly elevated temperatures compared to primary drying to facilitate the removal of bound water without causing product degradation.

- Duration: Secondary drying may take longer than primary drying, as it aims to achieve lower moisture levels to prevent microbial growth and maintain product integrity. and the following list of significant points about secondary drying

-

Example: In the production of lyophilized antibiotics, secondary drying ensures that residual moisture is sufficiently removed to prevent microbial contamination and maintain the antibiotic’s potency throughout its shelf life.

Here’s a table highlighting the key differences between primary drying and secondary drying in lyophilization:

| Aspect | Primary Drying | Secondary Drying |

|---|---|---|

| Process Description | Initial phase, where majority of water is removed. | Follows primary drying and targets residual moisture. |

| Mechanism | Sublimation: Ice converts directly to vapor. | Desorption: Bound water molecules are removed from product. |

| Temperature | Low temperatures, typically above collapse temperature | Slightly elevated temperatures compared to primary drying. |

| Objective | Removal of bulk water from product. | Removal of bound water to ensure long-term stability. |

| Duration | Generally shorter compared to secondary drying. | Secondary drying takes longer to achieve the desired moisture content levels. |

| End Point Detection | It is crucial to initiate secondary drying. | Indicates completion of drying process. |

| Control Challenges | Monitoring temperature and pressure dynamics. | Ensuring sufficient desorption without product damage. |

Process step of primary and secondry drying

| Sr No | Stage | Time (Minutes) | Temperature

°C. |

Pressure mbar |

| 01 | Primary Drying | 1 | 45 | 0.500 |

| 02 | Primary Drying | 5 | 45 | 0.700 |

| 03 | Primary Drying | 1 | 30 | 0.500 |

| 04 | Secondary Drying | 5 | 30 | 0.500 |

| 05 | Secondary Drying | 1 | 30 | 0.500 |

| 06 | Secondary Drying | 5 | 20 | 0.500 |

| 07 | Secondary Drying | 1 | 5 | 0.700 |

| 08 | Secondary Drying | 5 | 5 | 0.700 |

This table presents a series of drying stages in a lyophilization (freeze-drying) process, detailing the duration (time), temperature, and pressure conditions for each stage you are set as per your product required. Here’s a breakdown of the table’s components:

Explanation of the Table Components

- Sr No: This is the serial number that indicates the sequence of the stages in the drying process.

- Stage: This column categorizes the stages of the lyophilization process into two main parts:

- Primary Drying: This phase removes the bulk of the water from the product by sublimation, where ice converts directly to vapor without becoming liquid.

- Secondary Drying: This phase aims to remove the remaining bound water from the product, typically at lower temperatures and pressures.

- Time (Minutes): This indicates the duration of each stage in minutes. For example, the first stage of primary drying lasts for 1 minute.

- Temperature (°C): This column shows the temperature maintained during each stage. For instance, during the first stage of primary drying, the temperature is set to 45°C.

- Pressure (mbar): This indicates the pressure within the freeze-drying chamber during each stage. It affects the sublimation process; for example, the first stage is conducted at a pressure of 0.500 mbar.

Conclusion

Primary and secondary drying are essential for optimizing lyophilization processes and ensuring the quality and efficacy of lyophilized products. By carefully controlling temperature, pressure, and duration, manufacturers can achieve optimal drying conditions, resulting in stable, long-lasting products with retained biological activity.

FAQs

What is the primary drying phase in a freeze dryer?

The primary drying phase in a freeze dryer is the initial stage, where the majority of water is removed from the product. It involves sublimation, where ice directly transitions into vapor without passing through the liquid phase.

What is the secondary drying stage of desorption?

The secondary drying stage of desorption is the subsequent phase following primary drying in freeze-drying. It focuses on removing residual moisture from the product, targeting bound water molecules. This stage often employs slightly elevated temperatures to facilitate the removal of bound water without causing product degradation.

What are the three stages of lyophilization?

The three stages of lyophilization are freezing, primary drying, and secondary drying. Freezing involves freezing the product to form ice crystals. Primary drying removes the majority of water through sublimation, and secondary drying targets residual moisture to ensure long-term stability.

What is the temperature of primary drying in freeze-drying?

The temperature of primary drying in freeze-drying is typically maintained below the product’s collapse temperature. But above its glass transition temperature,. This balance is crucial to prevent product collapse or degradation while facilitating the sublimation of water from the frozen product.