Lyophilizer shelf temperature mapping plays a pivotal role in ensuring optimal product quality and process efficiency. With precise control over shelf temperatures, manufacturers can achieve uniform drying rates, minimize product degradation, and optimize overall production processes. In this article, we delve into the importance of shelf temperature mapping, guidelines and norms, challenges, recommended equipment requirements, and best practices for conducting shelf temperature mapping studies.

Table of Contents

ToggleKey Takeaways

- Lyophilization is a critical process in various industries, particularly the pharmaceutical sector.

- Ensuring optimal temperature control during the lyophilization process is crucial for maintaining product quality and process efficiency.

- Lyophilizer shelf temperature mapping is essential for understanding and optimizing the temperature distribution within the lyophilizer.

- Proper shelf temperature mapping helps identify hot and cold spots, ensuring consistent product quality and process reliability.

- Adherence to industry guidelines and the use of specialized equipment are key to conducting effective shelf temperature mapping studies.

Introduction to Lyophilizer Shelf Temperature Mapping

Importance of Temperature Control in Lyophilization

Temperature control is key in lyophilization. It makes sure drying happens evenly and keeps the product quality high. This process removes ice or water from products without losing the volatile molecules. Freezing vials to -40 degrees C and creating a vacuum of 100 milliliters is common. Then, raising the shelf temperature to -20 degrees or more can speed up drying.

Impact on Product Quality and Process Efficiency

Keeping a tight control on temperature during lyophilization boosts both product quality and efficiency. This method is quite costly in pharmaceuticals, and long drying times can increase costs and risk equipment failure. It’s important to make freeze-drying cycles as short as possible without lowering product quality. Scaling up from lab to production can also save money. Proper temperature control is essential for this. Lyophilization uses less heat, which keeps the powder intact and stable. But it can make the process longer because it dries at low heat.

“Ensuring uniform temperature distribution across freeze dryer loading shelves ensures consistent drying rates for all products.”

Why is shelf temperature mapping important?

Controlling shelf temperature is a fundamental process parameter that directly impacts product quality. Achieving uniform temperature distribution across lyophilizer loading shelves ensures consistent drying rates for all products. By adjusting the sample’s heat input, manufacturers can maintain safe and optimal process temperatures throughout the entire cycle, thereby enhancing product quality and minimizing processing time.

Norms and Guidelines for Shelf Temperature Mapping

ISO 13408-3 Norm Requirements

The ISO 13408-3 Norm outlines the requirements for shelf temperature distribution studies in lyophilizers. It emphasizes the importance of identifying inter- and intra-shelf temperature variations to ensure compliance with specifications. However, conducting temperature mapping studies poses challenges, especially in high-vacuum environments where conventional contact sensors may not be suitable.

The ISO 13408-3 Norm sets rules for checking temperature in lyophilizers. It says these tests must show how temperatures change between and within shelves and meet product standards. But it doesn’t give a clear step-by-step guide, causing confusion among those working with freeze dryers and quality control teams.

ISO 13408-3 Norm suggests using wireless data loggers for measuring shelf temperatures. These loggers work from -60 to +60°C and can handle very low pressures. During these tests, temperatures are checked from -60 to +60 °C, covering all shelves. It’s advised to measure at 5 spots per shelf on full and empty shelves to get a full picture.

The Norm gives basic rules for checking shelf temperature but lacks a detailed guide. This has made it hard to standardize and ensure consistent temperature mapping in the pharmaceutical freeze-drying field.

“The ISO 13408-3 Norm describes the guidelines for Shelf Temperature Distribution and mentions the need to demonstrate conformance with specifications through temperature studies.”

Recommended Measuring Equipment Requirements

To overcome these challenges, manufacturers require non-conductive, minimally invasive, and flexible sensors with wireless data loggers. These sensors should provide direct contact with the shelf surface, ensuring accurate temperature measurements without compromising the integrity of the vacuum-sealed chamber. Additionally, wireless data loggers must operate within a wide temperature range and be capable of real-time data collection and display.

For accurate temperature mapping in lyophilizers, you need special equipment. This equipment must handle the unique conditions of freeze-drying systems. Researchers and manufacturers have created non-conductive sensors and wireless loggers to solve the problem of monitoring temperature in vacuum-sealed chambers.

Non-Conductive and Minimally Invasive Sensors

Sensors for temperature mapping must not interfere with the freeze-drying process. They should be made of non-conductive, flexible materials. These can be placed on the shelf without breaking the vacuum seal. They need to read temperatures accurately, from -85°C to 140°C, with great precision and consistency.

Wireless Data Loggers and Real-Time Data Collection

Wireless data loggers are key for efficient temperature mapping. They work well in the low-pressure, cold environment of lyophilizers. These loggers send data in real-time to a central system. They should measure temperatures from -85°C to 140°C, humidity from 0% to 100%, and pressure from 0 to 10 bar absolute (0 to 130 psia).

Using non-conductive sensors and wireless loggers helps lyophilizer makers and pharmaceutical companies map temperatures well. This setup lets them check thermal uniformity, equipment limits, and performance. It ensures freeze-drying systems work well and are optimized.

Comparing Thermocouples and Data Loggers for Mapping freezer-Dryer Shelves

Using thermocouples for thermal validations and mappings, including freeze-dryer shelves mappings, has been common. However, because of the numerous measurement points involved, mapping a freezer with thermocouples can be challenging and time-consuming, leading to increased downtime for production equipment.

| Comparing Thermocouples and Data Loggers for Mapping freezer-Dryer Shelves |

|---|

| Criteria | Thermocouples | Data Loggers |

|---|---|---|

| Cost | Relatively inexpensive | Generally more expensive |

| Installation | Requires careful placement | Easy to install and relocate |

| Measurement Points | Limited by number of thermocouples | Can monitor multiple points |

| Data Collection | Manual recording | Automated data collection |

| Accuracy | High accuracy | Consistent accuracy |

| Downtime | May increase downtime | Minimizes downtime |

| Calibration | Requires periodic calibration | Calibrated before deployment |

| Accessibility | Limited accessibility during | Accessible remotely |

| operation |

This table provides a comparison between thermocouples and data loggers for mapping freezer shelves, considering factors such as cost, installation, measurement points, data collection, accuracy, downtime, calibration, and accessibility.

How to Perform Shelf Temperature Mapping Correctly

With the current norms providing limited guidance, it is imperative to establish best practices and standardized operating procedures for conducting shelf temperature mapping studies. This involves determining the optimal number of measuring points and their positions on each shelf, as well as the temperature settings during both the cooling and heating phases.

lyophilizer shelf temperature mapping

Lyophilizer shelf temperature mapping is key in the pharmaceutical world. It makes sure lyophilized products stay stable and quality checked. This method measures temperature at many points on the shelves to understand the drying process better. Knowing the shelf temperatures helps make the drying process better, keeps products consistent, and follows rules.

Mapping shelf temperatures helps spot hot and cold spots in the drying chamber. This lets makers adjust shelf positions and drying settings for even temperatures. For big drying operations, keeping product quality the same on all shelves is very important.

| Sensor Type | Accuracy | Compliance | Advantages |

|---|---|---|---|

| Tempris Sensors | ± 0.7°C | 21CFR Part 11, GAMP 5 |

|

| LyoPro Data Loggers, kaye system | – | FDA 21 CFR Part 11 compliant |

|

Keeping an eye on temperature is key from start to finish of freeze-drying. Different sensors, like thermocouples and RTDs, measure important temperatures. Placing sensors right and keeping them in good shape is important for good data and control.

Using advanced tools like Tempris and LyoPro helps makers map shelf temperatures well. This leads to better drying processes and high-quality products for patients.

“Accurate temperature monitoring is the foundation for ensuring product quality and process efficiency in lyophilization.”

How to perform shelf-temperature mapping or shelf temperature distribution test in a freeze dryer

Objective: The objective of this test is to verify that all the shelves in the lyophilizer attains the required temperature at different set points and remain within a state of control.(Mbar)

Set parameter for temperature mapping study of freeze dryer

| Sr.N0 | Phase | Time (Minutes) | Temperature (°C) | Pressure (Mbar) |

| 1 | Loading | 11 | 20.0°C | – |

| 2 | Freezing | 6 | 20.0°C | – |

| 3 | Freezing | 45 | 0.0 | – |

| 4 | Freezing | 180 | -55.0°C | – |

| 5 | Freezing | 80 | -55.0°C | – |

| 6 | Primary drying | 79 | 0.0 | 100 mbar |

| 7 | Primary drying | 81 | 0.0 | 100 mbar |

| 8 | Secondary drying | 62 | 65.0°C | 100mbar |

| 9 | Secondary drying | 81 | 65.0°C | 100 mbar |

| 10 | Secondary drying | 55 | 20.0°C | 100 mbar |

| 11 | Stoppering temperature | 11 | 20.0°C | 1000 mbar |

The table outlines the set parameters for conducting a temperature mapping study of a freeze-dryer, which is essential for validating the uniformity and reliability of temperature and pressure conditions during freeze-drying cycles. Here’s a detailed explanation of each phase and its associated parameters:

1. Loading Phase

- Duration: 11 minutes

- Temperature: 20.0°C

- Pressure: Not specified (-)

- Purpose: The initial phase where products are loaded into the freeze dryer at ambient temperature. No vacuum or pressure control is applied yet

2-5. Freezing Phase

This phase gradually reduces the product temperature to freeze it solid.

- Step 2: 6 minutes at 20.0°C

- Initial cooling step to stabilize the system.

- Step 3: 45 minutes at 0.0°C

- Cooling begins to bring the product closer to the freezing point.

- Step 4: 180 minutes at -55.0°C

- A significant cooling step to freeze the product completely, ensuring ice formation.

- Step 5: 80 minutes at -55.0°C

- Maintains the product at the set freezing temperature to ensure uniform freezing.

6-7. Primary Drying Phase (Sublimation)

This phase removes the ice by sublimation under controlled pressure and temperature conditions.

- Step 6: 79 minutes at 0.0°C and 100 mbar pressure

- Step 7: 81 minutes at 0.0°C and 100 mbar pressure

- The product is maintained at a low temperature (just above freezing) and under vacuum to allow ice to sublimate into vapor without melting.

8-10. Secondary Drying Phase (Desorption)

This phase removes unfrozen water molecules to reduce moisture content further.

Step 8: 62 minutes at 65.0°C and 100 mbar pressure

-

- Temperature is raised to desorb bound water while maintaining controlled pressure.

- Step 9: 81 minutes at 65.0°C and 100 mbar pressure

- Continuation of drying to ensure complete removal of moisture.

- Step 10: 55 minutes at 20.0°C and 100 mbar pressure

- Temperature is lowered to stabilize the product and prepare for stoppering.

11. Stoppering Phase

- Duration: 11 minutes

- Temperature: 20.0°C

- Pressure: 1000 mbar (ambient pressure)

- Purpose: The chamber is brought back to atmospheric pressure, and the vials are sealed (stoppered) to ensure product sterility and integrity.

Acceptance criteria: Temperature defference on the shelf from mean:±2.0°C, temperature defference per shelf package from mean ±2.0°C, Temperature defference between heat transfer fluid inlets and outlet ≤2.0°C (defference between sensor TE3.1 and sensor TE3.8

Implementation: Possible instruction and notes in the test documents are to be considered. the freeze drying unit must be switched on and all supply media must be connected and present. No failure massages , whichhave an impact on the implementation , are displayed on the SCADA system. the tester must be appropriately assigned on the freeze drying unit and SCADA system

Calibration: The thermocouple have to be calibrated prior to be measuring and after the measuring (pre calibration at 40°C to -40°C) the report of the calibration must be attached to this procedure

Key Takeaways,

- Temperature Control: Ensures precise freezing, sublimation, and drying conditions for consistent product quality.

- Pressure Management: Maintains appropriate vacuum conditions during drying phases to facilitate sublimation and desorption.

- Validation Goal: The mapping study ensures that all parts of the freeze-dryer (shelves, chamber, etc.) meet set parameters uniformly.

Test procedure:

- Check the calibration status verification of all the thermocouple before starting activity

- before starting the temperature mapping of freeze dryer, it should be clean as per respective standard procedure and make entry in sequential log of freeze dryer

- Ensure chamber evacuationprior to the start of temperature mapping study with required vacuum level of 300 mbar to achieve desired result.

- The entry of qualification activity should be done in the equipment log book.

- performed one run of temperature mapping in a standard lyophilization cycle.

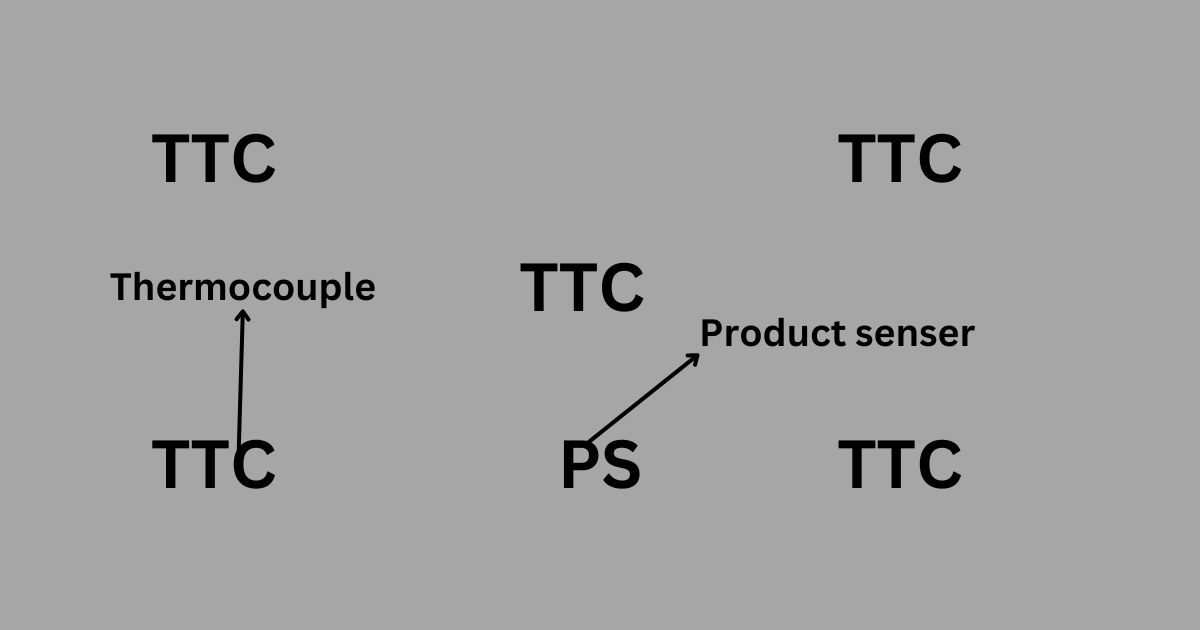

- Place the thermocouple in each shelf of the freeze dryer (four corners of the shelf and one at the center of the shelf) and attach the product sensor of the freeze dryer in the middle of the front side of the shelf, as shown in the below photo

- TTC thermocouple, PS-product senser

- Performed at three different temperature on a static rating

- rang: -45 (0 °C), 0.0 (0 °C), 80.0 (0 °C)

- Run the freeze dryer temperature mapping cycle as per set parameter mentioned in the protocol at -55.0 °C. 0.0(0 °C),65.0(0 °C)

- After achieving the set temperature, maintain the temperature for 80.0 minutes and do temperature mapping of all thermocouples for the last 20 minutes for the validation system after the 60-minute stabilization period.

Acceptance criteria:

On each shelf, the average temperature for the five thermocouple should not vary more than 2.00 °C from the reading of the individual hermocouple on that shelf at every minute of the data logging at static condition

The avaerage temperature of the shelf should not vary by more than 5.0 °C at every minutes of the data logging at static condition

At the mid point of the static period, the controlling senser temperature (temperature of silicon oil) should not vary by more than 5.00 °C from the individual product probes on shelves

The product senser temperature should not vary by more than 5.00 °C from the average temperature of the individual shelf. Shown by the thermocouple placed on the shelves during the period of data logging in the static condition every minute

Summary: During the temperature mapping activity, there are 5 thermocouples placed on each shelf (4 on the diagonal and one in the middle). The probes near the inlets and outlets for the silicon oil on each shelf are the crucial points and show the temperature of the shelf near the inlets and outlets. Hence, these points have to be functional after the run fopr each shelf. However, the other probes which are the places on the shelves other than inlets and outlets, can be considered for exclusion only if found nonfunctioning during validation run

For the lyophilization, having 15 shelves out of 75 thermocouples placed—a minimum 72—should be functional. And on each shelf, the number of probes that should be functional should be at least 4 out of 5

For the lyophilization, having 13 shelves out of 65 thermocouples placed, a minimum 62 should be functional. And on each shelf, number of probes that should be functional should be at least 4 out of 5

For the lyophilization, with 12 shelves, out of 60 thermocouples placed, a minimum 57 should be functional. And on each shelf, number of probes that should be functional should be at least 4 out of 5

For the lyophilization, having 11 shelves, out of 55 thermocouples placed, a minimum 52 should be functional and on each shelf, number of probes that should be functional should be at least 4 out of 5

Summary: Based on the above rational, the proposed number of thermocouples that can be non-functional during run can be maximum 03, and rest of the probes should be properly functional

Observation

Set up report verification: Set the required parameter in the thermacouple system as per the below table. And verify the set-up report with the actual required parameter, as well as check the set-up report printout.

Challenges in Shelf Temperature Mapping

In a variety of industries, including pharmaceuticals, shelf temperature mapping is essential to guaranteeing product quality and compliance. However, several challenges can impede the effectiveness of temperature mapping efforts. Let’s delve into some examples to better understand these challenges

Getting accurate surface temperatures in a lyophilizer or freeze dryer is tough. This is because it works in a high-vacuum environment. In this setting, most heat moves through radiation, not convection. So, using regular contact sensors to measure temperatures can be tricky. They might not work well for this special environment.

Measuring Surface Temperatures in High Vacuum

High thermal resistance and limited heat transfer by convection make temperature mapping hard in a high-vacuum setting. Regular contact sensors like thermocouples or RTDs might not give the right surface temperatures. This is because of the unique way heat moves around in this environment.

Limitations of Conventional Contact Sensors

Regular contact sensors have big limitations in a high-vacuum environment. This means we need special tools and methods for accurate temperature mapping. It’s important to overcome these challenges for successful lyophilization and keeping product quality high.

“The validation of lyophilization processes requires a thorough understanding of product and process conditions as well as equipment capabilities.”

Case Study: Shelf Temperature Mapping in a Pharmaceutical Company

In the fast-growing pharmaceutical freeze-drying field, mapping the temperature of lyophilizer shelves is key. It ensures the quality of products and makes the process more efficient. For a company that freezes dry products in vials, the process involves checking the temperature carefully.

They make sure the shelf temperature stays within certain limits. This is done to keep the product safe and effective.

- 50 loggers measure the temperature in all 4 corners and the center of all 10 shelves at +25, 0, and -20°C using atmospheric pressure

- 50 loggers measure the temperature in all 4 corners and the center of all 10 shelves at -20, 0, +20, and +40°C using vacuum

They check how the temperature changes across and between shelves at different temperatures. This helps them see if it meets the required standards. Keeping an eye on the temperature is crucial. It affects the quality of the product and how well the freezing works.

| Parameter | Value |

|---|---|

| Collapse Temperature | -15°C |

| Maximum Allowed Shelf Temperature | +35°C |

| Number of Loggers | 50 |

| Number of Shelves | 10 |

| Measuring Points per Shelf | 5 (4 corners, 1 center) |

| Temperatures Tested | +25, 0, -20°C (atmospheric pressure) -20, 0, +20, +40°C (vacuum) |

By mapping the temperature, pharmaceutical companies can improve their temperature mapping protocol in pharma. They follow temperature mapping guidelines for pharmaceutical industry. This ensures their products are always of high quality and freeze-drying works well.

“Accurate temperature monitoring is essential, as the product quality and the overall freeze-drying process efficiency are heavily influenced by the thermal behavior of the vials loaded on the shelves.”

Conclusion

Lyophilizer shelf temperature mapping is key for quality and efficiency in many fields, especially in pharmaceuticals. About 40% of the energy that goes to the product during drying comes from the shelf, so keeping the temperature right is very important. With a focus on making medicines for patients, lyophilization is crucial for keeping medicines stable.

By using the best methods and tools, makers can beat the challenges of measuring temperature in high-vacuum settings. New sensors and wireless loggers make it easier to check surface temperatures during drying. Using standard methods and new tech helps make better products and improve how things are made.

The need for medicines in areas like cancer, immune system studies, and brain research is growing. So, keeping an eye on lyophilizer shelf temperatures is more important than ever. Following rules, planning well, and using data helps make sure medicines are safe and work well, helping patients.

(FAQs) about Lyophilizer Shelf Temperature Mapping

What are the challenges associated with conducting shelf-temperature mapping studies?

Measuring surface temperatures in a high vacuum environment presents challenges due to thermal resistance and limited heat transfer by convection. Additionally, existing norms provide limited guidance on the procedure, making it challenging for operators and quality assurance departments.

What equipment is recommended for conducting shelf-temperature mapping?

Non-conductive, minimally invasive, and flexible sensors with wireless data loggers are recommended for accurate temperature measurement. These sensors should provide direct contact with the shelf surface and operate within a wide temperature range.

How should shelf-temperature mapping studies be conducted effectively?

Shelf temperature mapping studies should involve determining the optimal number of measuring points and their positions on each shelf. Additionally, temperature settings during both the cooling and heating phases should be carefully controlled to ensure accurate data collection.

What are the benefits of implementing standardized procedures for shelf temperature mapping?

Standardized procedures help ensure consistency and reliability in temperature mapping studies. Leading to improved product quality, process efficiency, and regulatory compliance. They provide clear guidance for operators and quality assurance departments, facilitating the smooth execution of temperature mapping studies.

What temperature should a condenser be at for lyophilization?

The condenser temperature for lyophilization is typically maintained at around -80°C to -90°C.

What is the temperature of a freeze dryer?

The temperature of a freeze dryer generally ranges from -50°C to -70°C during the primary drying phase.

What does the ISO 13408-3 Norm say about shelf temperature distribution?

The ISO 13408-3 Norm talks about checking shelf temperature to find any hot spots. It makes sure the temperature is even across the shelves as needed.

What is the importance of temperature control in lyophilization?

Keeping the shelf temperature steady is key to making quality products. It makes sure all products dry at the same rate. This is crucial for product quality.