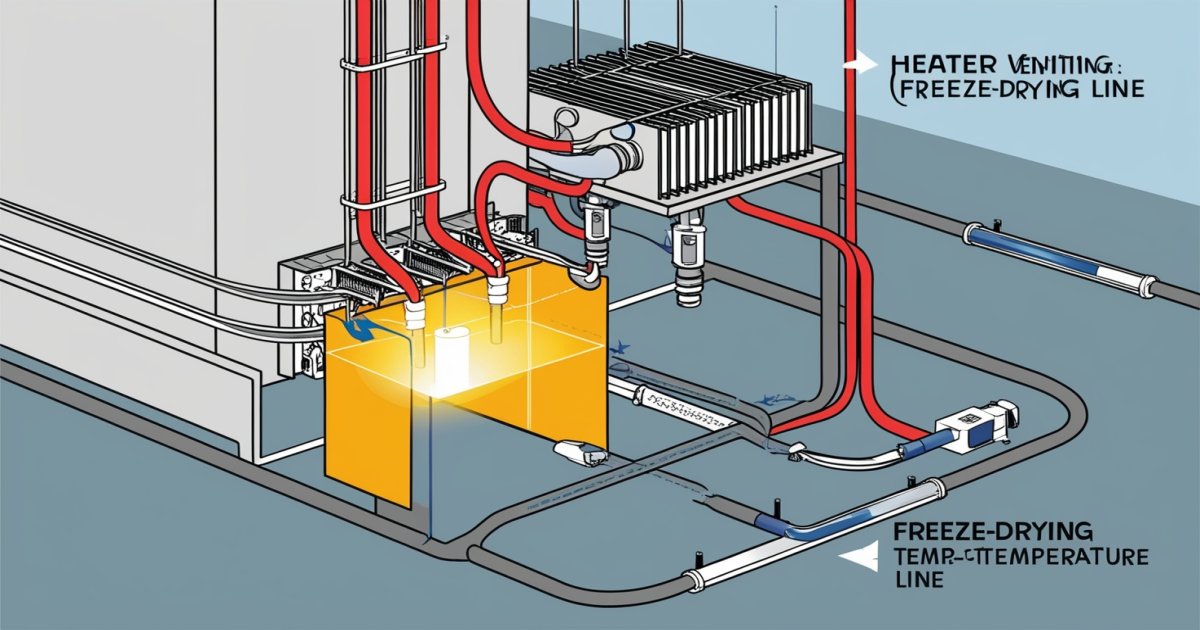

Heater Venting Line Excess Temperature During Freeze Drying: Causes and Solutions

In freeze-drying processes, maintaining optimal temperature conditions is crucial for effective operation and product quality. This occurs when the temperature in the venting line exceeds safety limits, causing the excess temperature safety switch to shut off the heaters. Understanding the causes and solutions for this issue is essential for ensuring smooth and efficient freeze-drying operations.

Key Takeaways

- Heater venting line excess temperature occurs when the venting gas temperature exceeds safety limits, causing automatic heater shutdown.

- The main causes include interrupted or defective switch connections and insufficient gas flow in the venting heater.

- Solutions involve routine maintenance, monitoring gas flow, and calibrating the system to prevent excess temperature issues and ensure smooth operations

What is Heater Venting Line Excess Temperature?

Heater venting line excess temperature refers to a situation where the temperature of the venting gas line becomes too high. When this happens, the safety switch detects the excess temperature and automatically turns off the heaters to prevent damage or hazards. Once the temperature drops back to a safe level and the switch resets, the heaters are turned on again.

Causes of Heater Venting Line Excess Temperature

Several factors can contribute to heater venting line excess temperature during freeze drying:

-

Interrupted or Defective Switch Connection

- Description: The connection to the safety switch may become interrupted or the switch itself may be faulty. This can cause the system to inaccurately detect excess temperature, leading to unnecessary heater shutdowns.

- Solution: Regularly inspect the connecting lines and safety switches to ensure they are functioning correctly. Replace any defective components to maintain accurate temperature monitoring.

-

Low Gas Flow in the Venting Gas Heater

- Description: If the gas flow in the venting gas heater is insufficient, it can lead to overheating of the venting line. This inadequate gas flow can trigger the safety switch, resulting in heater shutdown.

- Solution: Ensure that gas flow rates are adequate for proper venting. Regularly check and adjust the gas flow settings as needed to prevent overheating.

Solutions and Preventive Measures

To address and prevent heater venting line excess temperature issues, consider the following measures:

-

Routine Maintenance and Inspection

- Perform regular maintenance checks on the heating system, including inspecting the safety switch connections and gas flow rates.

-

Monitor and Adjust Gas Flow

- Ensure that the gas flow in the venting gas heater is set to the correct levels for efficient operation. Adjust the flow rates as needed to maintain safe temperature conditions.

-

Regular System Calibration

- Calibrate the heating system regularly to ensure that all components, including safety switches and gas flow meters, are functioning correctly and accurately.

Impact of Freeze Drying Heater Venting Line Excess Temperature

In freeze-drying processes, managing the temperature of the heater venting line is crucial for maintaining efficiency and product quality. Excessive temperatures in the venting line can have several significant impacts:

- Reduced Efficiency

- Impact: High venting line temperatures can cause the heating system to cycle on and off frequently, leading to inefficiencies in the freeze-drying process.

- Product Quality Issues

- Impact: Inconsistent heating due to excess temperature issues can affect the uniformity and quality of the freeze-dried product. Temperature fluctuations may lead to incomplete drying or degradation of sensitive materials.

- System Downtime

- Impact: Frequent activation of the safety switch due to excessive temperatures can lead to unexpected system shutdowns. This downtime can disrupt production schedules and result in costly delays.

- Increased Maintenance Costs

- Impact: Persistent excess temperature issues may necessitate frequent repairs and replacements of components like safety switches or gas flow systems. This can lead to higher maintenance costs and reduced system longevity.

- Safety Risks

- Impact: Overheating in the venting line can pose safety risks, including potential fire hazards or damage to the equipment. Ensuring that the system operates within safe temperature limits is essential for preventing accidents.

Monitoring and controlling heater venting line temperatures during freeze drying is essential for ensuring efficient operation and maintaining product quality. Addressing excess temperature issues promptly can help avoid operational disruptions, reduce maintenance costs, and enhance overall safety

Conclusion

Heater venting line excess temperature is a critical issue that can impact the efficiency and safety of freeze-drying processes. By understanding the causes—such as defective switch connections or low gas flow—and implementing effective solutions, you can maintain optimal operating conditions and prevent unnecessary disruptions. Regular maintenance and proactive monitoring are key to ensuring the reliable operation of your freeze-drying equipment.

FAQs

What is a heater venting line?

Heater venting line excess temperature occurs when the temperature of the venting gas line exceeds the safe operating limit, causing the safety switch to turn off the heaters automatically. Once the temperature cools down and the switch resets, the heaters are turned back on.

How can I prevent heater venting line excess temperature issues?

To prevent these issues, regularly inspect the safety switch connections for any interruptions or defects. Additionally, ensure that the gas flow in the venting gas heater is adequate and conduct routine maintenance to keep the system calibrated and functioning properly.

What should I do if the heaters turn off due to excess temperature?

If the heaters turn off, allow the system to cool down. Check for any disruptions in the switch connection or issues with gas flow. Address any identified problems and ensure that the system is reset before turning the heaters back on.

How often should I perform maintenance on my heating system to avoid excess temperature issues?

Regular maintenance should be performed according to the manufacturer’s guidelines or at least once every six months. This includes checking switch connections, gas flow rates, and overall system performance to ensure everything operates within safe temperature limits.

Can low gas flow in the venting heater cause other problems?

Yes, low gas flow can lead to overheating, decreased system efficiency, and potential damage to the heating components. It is important to monitor and maintain proper gas flow to avoid these issues.